You can make a door with your own hands for several reasons. Someone has lumber left, someone likes to tinker, someone is sorry for the money to buy a finished product. The step-by-step instructions may vary depending on the materials available and the type of blade selected.

Advantages and disadvantages of wooden doors

The advantages and disadvantages of wooden doors are due to the physical characteristics of the natural material.

Positive qualities include:

- low thermal conductivity and frost resistance;

- strength;

- durability with proper handling and protection;

- environmental friendliness;

- low cost when manufactured on their own;

- various design options and the ability to implement unusual design solutions;

- maintainability.

The disadvantages of wooden products are flammability, change in geometry when exposed to moisture.

Taking into account the totality of properties, wooden doors are used as interroom doors, entrance doors in apartment buildings and internal additional doors in private buildings.

Brief classification

Starting to manufacture, they determine what parameters the design should correspond to.

Canvases made of wood are divided according to the characteristics:

- material of manufacture - coniferous or deciduous;

- finishing - painting, veneer, MDF, lining, etc .;

- opening method - swing, sliding, swinging, folding;

- functional purpose and location - entrance, interior, special;

- by internal filling - from solid wood, panel board, paneled, smooth.

Experienced craftsmen are capable of making any product that meets all classification parameters in a small home carpentry environment.

For a first-time experience, it is best for novice carpenters to start with simple wood products.

DIY design options

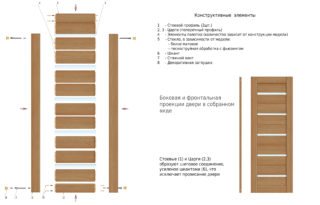

Door block - a structure that includes a box (frame), curtain, locking devices and awnings (hinges). Additionally, an opening angle limiter and a peephole are installed.

Solid wood doors

Solid wood products can play the role of an external door - they are distinguished by their strength, burglary resistance, and a long service life.

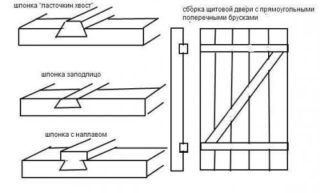

Doors are made of boards connected by the tongue-groove method or processed by planing with a fit that excludes gaps between individual elements.

Separate nodes are fastened with transverse bridges.

Entrance loops are made of oak, cedar or larch - they do not deform in conditions of high humidity and negative temperatures. Not suitable for outdoor use pine.

For bath complexes, including for doors to the steam room, pine, linden and alder are used.

The advantages of solid wood canvases include:

- good heat and sound insulating properties;

- durability;

- simplicity of restoration with giving the original appearance;

- presentable appearance, use in several types of design;

- the possibility of making recesses, decorative carving;

- giving any color with the help of stains, stains (stain that requires dilution), stains and tint varnishes.

The disadvantages include rapid destruction with an inappropriate choice of wood species.

To preserve their appearance and prevent decay, solid wood doors require regular maintenance with the use of antiseptics, impregnations, polishes and varnishes.

Manufacturing requires specialized tooling, wood handling skills and installation practice.

Shield

Shield structures are also called frame structures.

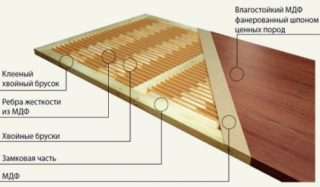

The product consists of longitudinal and transverse rails of the frame, between which the honeycomb filler is located. To impart sound insulating properties, the "honeycomb" is filled with cardboard, foam, mineral insulation, etc.

After making the frame, the canvas is sewn on both sides with sheets of fiberboard, MDF, plywood and other similar materials.

In places where locks, handles, hinges are installed, the width of the frame must be at least 100 mm with a height of at least 250 mm.

The advantages of panel doors include simplicity of manufacturing technology and inexpensive materials, which reduces the cost of the structure.

Panel doors with honeycomb filling are used only in the interior space of houses and apartments based on their resistance to climatic factors.

The structure resists mechanical stress poorly and cannot be used for installation at the entrance to a dwelling.

There are panel doors of solid filling with slats or bars. The front side of the canvases is sewn up with sheet materials. Products have an increased weight and require the manufacture of a frame of a reinforced structure.

Tsargovye

The special design of prefabricated doors is called tsargovaya.

Longitudinal boards are connected by several wide crossbars. Part of the canvas can be filled with glass, plastic and other materials. The entire surface is finished with a finishing material, there are no bulges and notches.

Tsargovy blocks are used as interior structures.

Paneled

Paneled doors are similar in design to side doors, but they are more difficult to execute and require special tools for manufacturing.

The structure consists of longitudinal and transverse beams of the frame, the space between which is filled with small figured details - panels.

Paneled structures are difficult to manufacture, therefore quality products have the highest price among other options.

Pine canvases, used only in the interior space. Larch, oak suitable for exterior doors.

Keyway

A door made of boards, assembled on dowels, is called a key door. It is a construction made of 40-50 mm thick timber, which are tightly fitted. Key grooves are made for connection in the canvas.

Fasten the structure with curly dowels.

The appearance of the keyed doors fits perfectly into the interiors of a bath or workshop. In the rooms of living quarters, such a design is rarely used or in very exotic semi-antique interior design solutions.

Keyed doors should not be confused with veneered doors - these are fundamentally different designs.

Veneered

Veneer is called thinly cut sheets from wood raw materials. The thickness of the plates is from 0.1 to 1 cm. The color depends on the type of wood and the method of finishing the raw materials.

Finished solid doors are covered with veneer.

Combinations of decorative materials made from different types of wood can give an interior an exclusive look.

It is undesirable to install veneered doors in places where physical impact on the structure is possible or in places where pets are kept. It is extremely difficult to restore the surface from scratches and damage on your own.

Currently on sale there are artificial types of veneer based on polymer films.

Sometimes, by staining, they imitate an inexpensive material for elite wood species.

Instructions for making wooden doors

The door block manufacturing process consists of several sequential operations:

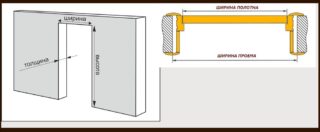

- measuring the dimensions of the opening in the wall;

- drawing development;

- frame manufacturing;

- assembly of the canvas;

- decorative finishing;

- installation and adjustment;

- installation of accessories.

Before starting work, they buy material and prepare tools.

To make a door from boards with your own hands you will need:

- a milling cutter for making grooves and drawing a pattern;

- hacksaw or jigsaw - for an accurate cut, the teeth of the tool or files must be small;

- planer and grinder;

- hammer, mallet;

- a set of chisels for sampling grooves for locks and hinges;

- screwdriver or drill;

- a workbench larger than the door leaf;

- clamps of different sizes;

- wood glue, brushes, sandpaper, stain, varnish or paint.

Depending on the desired appearance, you may need veneer, MDF, and other finishing materials.

Frame fabrication

If you plan to cover the door with a transparent varnish, choose the same type of wood for the door leaf and frame.

For strapping, a beam with a thickness of 4 cm or more is used, so that you can choose a groove for the canvas.

The outer size of the box is chosen 2–3 cm less than the minimum dimensions of the opening. This will allow you to have a headroom during installation, which will be needed to fit the door block.

The longitudinal and transverse strips are fastened with self-tapping screws, or by making cuts “in half a plank”.

Whether or not to make the lower crossbar of the box depends on the purpose of the door. In the entrance doors, a lower strip is made with a recess in half the thickness of the timber to prevent drafts.

For interior designs, bathrooms and kitchens, the lower crossbar is hidden in the floor. A gap is left between the floor covering and the canvas for air circulation.

Solid wood canvas

For manufacturing, use blanks with a thickness of more than 25 mm. Purchase grooved boards or make connections on their own.

The grooves and spikes in the boards must be at least ½ of the thickness of the material in height and depth.

The harness boards should be flat on one side. The grooves and spikes are removed with a plane.

Step-by-step instruction:

- Select high-quality material without cracks and large knots.

- Dry the tree indoors, avoiding direct sunlight.

- Sawing the boards according to the size of the canvas, take into account the width of the upper and lower crossbar, if provided.

- The canvas is assembled on the workbench, the joints are treated with carpentry glue.

- Clamps squeeze the resulting structure and leave to dry completely.

- If necessary, a pattern is selected using a router.

- Mark and sample surfaces for mounting hinges and a lock.

- The surface is cleaned first with coarse and then fine sandpaper.

- The surface is treated with stain or tinting impregnation. Before staining with opaque paints, the surface is treated with an antiseptic.

- Cover the surface with clear varnish or paint of the desired color.

After drying, the door leaf is installed in the frame, the door opening and the operation of the locks are regulated.

Shield

A simple manufacturing option is to assemble the frame and then fill the interior space.

Algorithm for assembling a panel door with solid filling:

- Collect the outer harness - the frame of the canvas. To do this, the side beams are connected to the jumpers - upper, lower, central. To create a rigid structure, spike-to-groove joints are used or samples are made in half the thickness of the bar parts.

- On one side of the frame, sheathing made of laminated MDF 10 mm thick, fiberboard or plywood is glued.

- The cavities inside the frame are filled with bars, which are attached to the cladding with wood glue.

- The second cladding panel is glued.

- They cut in hinges, locks, handles.

- Mount the door to the box.

At home, you can make a simplified version of the door with partial filling. The operations are carried out in the same way as for the fabrication of a canvas with a continuous filling, only instead of a continuous filling with bars, a lattice is made of MDF strips.

In the process of assembly, MDF is glued with its end to the surface, and for stability, wood bars 10-15 cm long are laid between the strips. It turns out a kind of fence.

Block installation rules

When installing doors, they take into account the peculiarities of operation, violation of the rules can render the entire structure inoperative or significantly complicate the use.

Important rules:

- The door should not occupy a large area of the room when opening. For example, the door to the bathroom should open outward, and it is better to open the canvas from the corridor to the room towards the room.

- They take into account the side to which the canvas will move, structures are right or left. The parameter is important to know when buying hinges, which can also be right and left.

- The installation of the frame begins only after the plaster has completely dried, if the wall is finished with it - after absorbing moisture, the frame may warp.

- Particular attention is paid to maintaining the vertical level of the frame. If it is skewed towards the outer or inner surface of the wall, the door will spontaneously open or close. The ideal position is when the blade remains stationary when opened to any angle.

Making a wooden door with your own hands is a fascinating process for a home craftsman. In addition to moral satisfaction, work can significantly save money. It is important to exercise care and patience when making. In this case, the result will delight the master and household members.

I myself like to tinker, but you must admit it is difficult to create a good thing without proper experience, and it is still difficult to find the appropriate material why are they stamping furniture from sawdust and fences from boards?