A do-it-yourself spiral staircase is usually made of wood or metal. The small dimensions of the structure and its elegance make it possible to mount it even in a small house (including a summer cottage).

Choice of design

Before making a spiral staircase, you need to decide on the type of construction. They differ in the height of the steps, the way they are fastened, the presence or absence of railings.

Structures are straight and rotary. Some of them are made in the form of a transformer. The ladder can be attached to the wall or stand isolated. Railings are made from different materials; most often wood and PVC are used for this. The staircase can be used to climb to the front door of the dwelling, to go to the next floor, basement or attic.

Mount types

For the manufacture of the structure, run-in steps are created. Assembly and bonding can be done in different ways. One of the most common options is radial using kosour. The steps in this case form a helical configuration. The most reliable and safe option is to use a wall surface to support it.

It is easy to build with your own hands a structure with the fastening of the steps to the main pillar and helical railings. The option with bolts is also practiced. It is attractive because the steps do not creak in this case.

Advantages and disadvantages

Spiral staircases are good for their compact form, so they are often chosen when arranging small-sized dwellings. They have an intricate appearance that is in harmony with the "antique" interior or a cozy wooden house. The design visually stretches the room with a low ceiling.

Due to the small amount of raw materials, the homeowner will save some of the savings. The dimensions also help to save space on the second floor due to the lack of the need for a large opening.

This design is well suited for climbing the attic in the cold season. In this case, the main flight staircase is equipped outside the building (on the street) and is used, for example, to carry up cabinets and other large things, and the spiral staircase is equipped inside the dwelling.

The screw design is not suitable for lifting furniture or bulky appliances. In addition, some people experience discomfort when climbing stairs in such a confined space.

Calculations of a spiral staircase

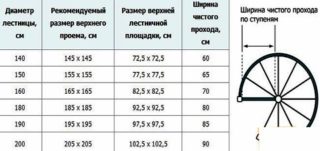

Before starting work, you need to make the necessary calculations and prepare a drawing of a spiral staircase with dimensions. It is desirable that already during the erection of the first floor of the building, the design documentation indicates the localization zone of the structure and the dimensions of the opening. A separate scheme is prepared for the circular corner areas of the opening.

The optimal march width is 0.9-1 m, and the slope angle is 45 degrees. The value of the last parameter is inversely proportional to the amount of space occupied by the resulting structure as a result. The minimum distance from the opening edge to the handrail is 0.1 m.

The number of steps can be found by determining the length of the structure. It is equal to the sum of the heights of the space between the floor and the ceiling and the overlap between the floors. This parameter must be divided by the height of one step (the recommended range is 0.18-0.22 m).For example, if you plan to build a structure with a height of 3 m, and the step rises by 20 cm, the total number of them will be 3: 0.2 = 15 pieces. When designing, you must comply with the norms of SNiP.

Material selection

Most often, the staircase to the second spiral is constructed of solid wood or metal. Sometimes the construction of a concrete structure with formwork is also practiced. Steps are also made of marble.

Wood

Hardwoods are best suited for home stairs. The resinous nature of coniferous wood makes it especially susceptible to fire, so such a material in this case is not the best choice. You can take solid oak, ash or maple. Beech is highly susceptible to water, so you should not use it for steps. Raw materials must be impregnated with compounds that protect against rotting and fungal attack. You can emphasize the texture of the wood by covering the surface with varnish.

Metal

Since the metal is not afraid of moisture, it is possible to assemble and install the staircase system on the street. It can lead to the attic, attic or to the main door located at a sufficient height. Typically the system includes rungs, bushings with washers, and a main strut. The latter can be made from a long pipe. The steps are connected with bolts and couplings.

DIY construction stages

When installing a spiral wooden staircase to the second floor with your own hands, you can make the main support and steps yourself or assemble a structure from ready-made elements. The latter path is suitable for those who do not have sufficient carpentry skills. The master needs to provide drawings and measurements.

If it is decided to carry out the work from scratch, it is recommended to pre-assemble the model, which includes three stages, to assess the correct dimensions and ease of lifting. If such a test was satisfactory, you can proceed to further actions.

- Steps are created from blanks using a milling machine. Do not forget about the preparation of the grooves for the sleeves. Parts should be sanded and varnished on top.

- A support element for the main tube, flange components and sleeves is made. The latter are sometimes replaced with rings made of wood. With the ability to work with a welding machine, the structure may be based on a metal frame.

- After completing the preparation of the components, you can begin to build the system. They put it on a plane, freed from the floor covering. First, mount the main rack. It must be strictly vertical, otherwise rolls will appear in different places of the structure. It is fixed to the floor with anchor parts.

- They install sleeves and steps. The latter during fitting fasteners can be covered with polyethylene so that the surfaces are not damaged.

Bolts or load-distributing jibs can be used for fixing. Then, the handrails are installed, consisting of racks and handrails. The latter are often made of PVC. For racks, it is possible to order balusters equipped with holes for metal studs.