A soft roof is a special type of covering that performs a protective and decorative function. Compared to rigid materials, it is easier to install, cheaper, and also characterized by a variety of species. For proper installation, a suitable sheathing for soft tiles is required. The structure is arranged so that it does not warp for a long time under the influence of external loads. It is the support for the soft floor.

General requirements

The frame for roll shingles must be strong, sufficiently rigid. The following requirements are imposed on it:

- accurate horizontal level without grooves and bulges;

- perfectly fitted joints;

- lathing step for OSB;

- the ability to withstand human weight, the mass of the roof under the influence of precipitation and wind.

For the installation of the lathing under the soft tiles, high quality materials are used, which ensure the durability of the coating. The tightness of the roofing tile depends on how flat the base will be.

Features of the arrangement of the lathing

When organizing the support layer, the state of the material from which it is made is taken into account. If it is warped or irregularities have formed on it, such elements are unsuitable for work. Since boards are more often used for work, they must be laid out with a tray. This feature should be taken into account if there is a risk of moisture getting under the roofing material through the joints of the sheets.

To make the bends of the tiles smooth and less noticeable, the front boards are rounded at the ends. The thickness of the material for the structure must be sufficient to withstand all possible load. However, the weight of the crate itself is also taken into account here. Do not make it too large, so as not to increase the load on the foundation of the building.

In the manufacture of the rafter system and frame, structural nuances are taken into account. The parameters of consumables depend on this.

Varieties of lathing for flexible shingles

The lathing for a soft roof is mounted with a continuous covering. There are 2 types of frames: single-layer and combined.

Single layer decking

When installing a single-layer base, all parts of the sheathing are nailed in the direction of the ridge to the rafter legs. For work, hewn boards, OSB boards or plywood sheets are used. The sparse version is not often used, as the soft coating will sag.

Double decking

In this case, several layers are combined, for the manufacture of which you can choose different materials. The first of them is a sparse crate for OSB on the roof. For its arrangement, the bars or boards are laid in acceleration. The second layer is made from boards, plywood or OSB sheets. Thanks to this scheme, it is possible to form a heat-insulating cake and a ventilation gap. This design is more suitable for modern flexible roofing materials.

Materials used

For the lathing device, plywood or OSB is used. Each material has its own characteristics:

- Plywood. The product must be waterproof and flexible. The coating is multi-layer, therefore it has a high functionality.The best option is considered to be FSF plywood, which is made from coniferous wood. The material has high mechanical strength, resistance to aggressive substances and moisture, and low weight. Since the product is treated with fire retardants and antiseptics even at the manufacturing stage, it is not subject to rapid ignition and biological factors.

- OSB. Due to the special production technology, the boards are not susceptible to moisture, are resistant to various atmospheric loads, and have a low weight. With the help of this material, you can equip a perfectly smooth base for a soft roof.

For plywood or OSB boards, tongue-and-groove boards of the same thickness are required. It is also allowed to use softwood edging elements. Their moisture content should not exceed 20%.

Sheathing step

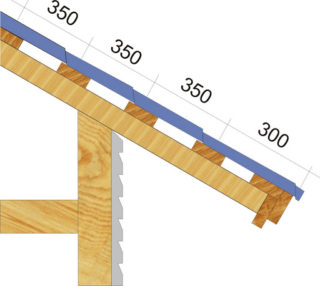

Compliance with the pitch of the sheathing under the shingles is the main condition for the strength and durability of the system. In a lattice structure, this parameter varies between 20-50 cm. For a soft roof, such a distance is too large if the system is single-layer. In a solid crate, the joints between the elements are minimal. The largest is 1 cm.

The boards are laid back to back. The acceptable seam size does not exceed 3 mm. In this case, the support for the soft roof will be strong enough, and the wooden elements will be able to change size under the influence of moisture and temperature. In this case, the lathing will not warp.

The correct calculation of the pitch of the rafters for a soft roof is also important. The thicker the plywood or OSB board, the larger it is.

DIY installation features

During installation, the technology must be strictly observed. It depends on the type of lathing.

Single layer

The single-layer lathing is mounted directly on the rafters. It is used if there is no need to form an insulation cake. For the manufacture of the structure, boards and boards of OSB, plywood are used. Unedged elements are not suitable for the first option. The boards are laid across the rafters. Their width is 10-14 cm, thickness - 2-3 cm. The lathing elements are fixed along the ridge with trays up. Laying is carried out from the bottom up using nails or self-tapping screws. The joints of the boards must fall on the rafters.

When using plywood, the sheets are mounted with the long side parallel to the ridge. The vertical joints of adjacent rows must be done so that they do not coincide. Self-tapping screws or punched nails are used for fastening. The size of the step between them is 30 cm. At the edges, the distance between the fasteners is 10 cm.

Double

The combined lathing is mounted from the first layer of boards laid in a row, as well as the second from panel materials.

The arrangement of the structure contains the following stages:

- Construction of a counter-lattice. This stage is needed if roof insulation is used. Wooden bars are screwed along the rafter legs. A waterproofing layer is laid on such a base over the insulation.

- Installation of the first layer. Boards are screwed onto the base.

- Laying the second layer of panel board materials.

The advantage of a double-layer lathing is the presence of a ventilation gap between the counter-lathing and the main structure. Heat-insulating mats are placed between the bars. After installation, a lining is laid on the base, and then soft tiles.