Making sauna stoves with their own hands has become widespread in the private sector, where real estate owners prefer the autonomy and independence of central communications. Competently designed products are compact, convenient and safe to use, have high efficiency and good economy. If you make a stove for a bath with your own hands, you can save and improve your skills and skills in working with metal and stone.

Metal sauna stoves

Heating boilers for steam rooms differ in size, shape and finishing options.

Sauna stoves made of metal have a common structure:

- Housing. It can be in the form of a cube, parallelepiped, cylinder of vertical or horizontal orientation. Serves for placement of functional parts for fuel and removal of combustion products.

- Firebox. Box, limited in the body, for receiving and burning firewood. In the lower part there is a grate, and in the upper part there is an opening for the removal of smoke and pyrolysis gases.

- Ash pan. Located under the grates, it is needed to collect ash and ash. The door is used to adjust the draft in the system.

- Kamenka. Metal basket with stones. Designed for more efficient heat distribution throughout the steam room. As a heat exchanger, ordinary cobblestones or talcochlorite are used - a unique mineral of the metamorphic type with healing properties.

- Chimney. Creates the necessary draft, removes smoke from the combustion chamber. Usually made from steel pipe.

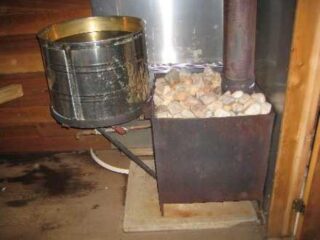

Sometimes a stove is installed in a bath with a water tank. The container is located directly above the boiler and can be equipped with a tap for supplying water to heating elements or to a basin.

Varieties of designs

Before making a boiler for a steam room, you need to evaluate its ratio to the size of the room and the level of safety.

A do-it-yourself wood-fired sauna stove can be made in this design.

- Closed. The structure is compact and almost completely eliminates the likelihood of burns. The boiler led out into the steam room is lined with walls made of refractory bricks, and completely covered with stones from above.

- Open. The side parts do not close, which ensures faster and stronger heating of the room. A metal box is welded onto the boiler lid, into which cobblestones are poured. The capacity for water is made of a smaller volume. Such a stove for a bath with a tank with your own hands is done simply and quickly.

- Combined. In such furnaces, thermal energy is used to the maximum. In the design, a firebox is distinguished, equipped with two valves, a grate and a blower, two pipes with four holes for a pipe and a bypass elbow.

Heating devices are also distinguished by the type of fuel used:

- wood-fired - require constant refueling and supervision, but can be used autonomously, regardless of the presence of communications;

- electrical - modern, reliable, equipped with high-class protection devices that consume a large amount of energy, which means they are expensive to operate;

- gas - practical, safe, economical devices with the ability to adjust the heating power.

The choice is made based on the characteristics of the premises, financial capabilities and skills of the master.

The simplest metal sauna stoves

When designing a sauna, the decision on the type and characteristics of the stove is made after evaluating all the associated factors. Sometimes the choice is made in favor of the simplest structures as a temporary solution in the absence of funds, equipment or when waiting for any favorable conditions for the construction of more expensive and efficient structures.

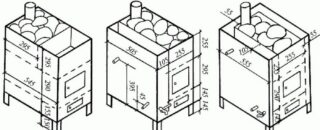

Boiler shape options:

- Cubic. They are a classic potbelly stove with an internal firebox. An ash pan, grate bars are placed inside the body, and a pipe is placed on top, which is led out through the wall to the street. Safety is ensured by a high chimney and air duct supply to the blower. It is the most common way to set up a steam room quickly and inexpensively.

- Vertical. A good solution for small steam rooms. They take up little space, they are fenced off from the walls with insulating material. The boiler can contain two or three compartments - a firebox, an internal heater, a water boiler. To redirect heat fluxes, a screen is installed on top.

- Horizontal with a remote firebox. It is more difficult to make such devices, since you need to make and insulate a passage in the wall. However, the costs are paying off. Being in the steam room is comfortable, safe, there is no risk of fire and carbon monoxide poisoning. The portable firebox also heats the dressing room, which is convenient and practical.

Rectangular stoves are more durable than round ones, since the iron in the corners heats up less, the body retains its shape better and longer. A tall boiler gives more design possibilities, but most of the heat is released upward, which requires the installation of additional devices in its direction downward and to the sides.

Manufacturing process

To weld a heating boiler for a sauna, you can use a wide variety of materials, including waste materials:

- an old gas cylinder after thorough cleaning;

- a barrel with thick walls;

- disks from wheels;

- a piece of metal pipe;

- metal sheets with a thickness of at least 5 mm.

In addition, you will need:

- grate fittings;

- handles, hinges and door latches;

- asbestos cord for sealing and lining;

- fireclay and refractory red bricks;

- clay and sand;

- two-layer chimney pipe.

If you have everything you need, you need to weld the body, attach the legs to it in accordance with the previously drawn up scheme, and start making the furnace.

First, a firebox is made:

- Marking. Cutting holes for blower and fuel loading. On the inner side of the body, stops are attached for attaching the grate. You need to cook carefully, it is better to point it, so as not to burn through the body and not leave bulges on it from overheating. You can make the grill yourself or buy a finished product in the store.

- Fastening the doors. The hinges are fastened by welding, bolts or rivets. It is advisable to use the last two methods so that the products do not deform from heating.

- Carrying out lining. Fireclay bricks are glued to the walls of the furnace. This will prevent the metal from glowing red, absorb excess heat and extend the life of the structure.

The next step is to make the heater. One of the technologies is used:

- Superficial. After taking measurements, a cage is made of reinforcement with a diameter of 10-12 mm. Then the box is installed on the boiler lid and welded to it. Deaf walls should not be made in order to ensure better heating of the room and free exit of steam after water supply.

- Internal. A hole is made in the body, a grate is placed under the stones. Water can be supplied with a mug through an opening or through an opening from a tank with a tap.

The cavity is filled with special minerals - talcochlorite, diabase. The use of mica-containing rocks, flint and granite is not allowed.

Making a tank for heating water is not one of the mandatory activities, but it allows you to make the process of visiting the bath more comfortable and safe. This structure serves as a supply of water to the stones, and for subsequent hygiene procedures in the shower.

For the manufacture, the same materials are used that went to the boiler, only their walls can be thinner, since the product is not exposed to contact with an open flame. The ends of the pipe are plugged, a hole is made from above for refueling, a tap is inserted from below. The tank is attached to the stove, heating occurs from direct contact with the material, as well as from hot smoke.

How to improve the characteristics of a metal stove

Having drawings of a metal bath stove, you can assemble reliable and functional products. But there is always an opportunity to make their work more efficient and their appearance more attractive.

To maintain constant traction and not worry about a possible fire, double pipes with a deflector will allow. Soot does not linger in such channels.

You can improve the design of the hearth with clinker tiles and tiles. These coatings tolerate heat and sudden changes in temperature very well.

It is advisable to take large stones. They retain heat longer and do not cool down immediately after sprinkling with water.