Kuznetsov's stove is installed in baths, dachas, houses, it is used to heat the garage, workshop. Varieties of designs are performed in the form of a Russian stove, fireplace, open hearth - all options deserve the attention of users.

- The history of the bell furnace

- Advantages and disadvantages

- Features of designs I. V. Kuznetsov

- Double bell oven

- Heating and cooking option

- Device characteristics

- How to fold the stove I. V. Kuznetsov

- Calculation of dome heating devices

- Performance indicators of the bell method

- Furnace designs for low-rise buildings

- Order scheme and materials for construction

The history of the bell furnace

In the early 60s, a talented craftsman began to search for a solution to how to obtain a large heat output with a small amount of fuel. After more than half a century, Kuznetsov's furnaces became the most effective. The first structure was built immediately after the start of research. Since then, the unique development has been repeatedly modernized as a heating device and a device for preparing hot food.

A team of like-minded designers has conducted more than one and a half hundred studies. They were attended by engineer I. S. Podgorodnikov, Russian professor V. E. grum-Grzhimailo. The developments covered the entire range of models of household stove devices. As a result, the efficiency of modern Kuznetsov furnaces reaches 80 - 94%. The design is known for its positive characteristics and good user reviews.

Advantages and disadvantages

The efficiency ratio exceeds that of traditional stoves, in which it is in the range of 70 - 85%. In Kuznetsov's designs, soot completely burns out, so the period between two adjacent cleanings is estimated at 3-4 years.

Advantages of the inventor's models:

- traction is carried out due to the voids inside (caps), and not channels, so less brick leaves;

- stoves run on any fuel, not only wood;

- the use of a short smoke channel also saves money on the arrangement;

- there is a uniform heat transfer throughout the day;

- there is the possibility of heating several levels of the house from one device;

- DHW and steam-water heating circuits are inserted into the structure, it is combined with a hob, stove bench, oven, fireplace.

Complex masonry is being performed, which must be fully mastered before starting construction. Furnaces of this category have significant weight, are massive, so a solid foundation is needed.

Features of designs I. V. Kuznetsov

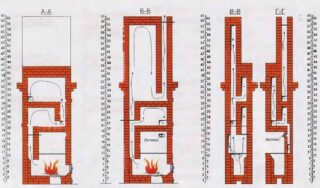

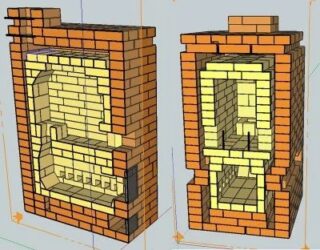

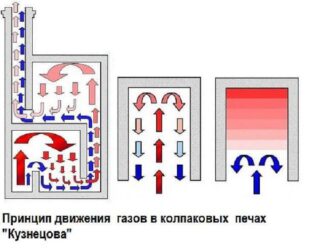

The heated smoke rises, lingers in the dome, and descends after gradual cooling. All thermal energy is transferred to the brickwork, since the contact time is increased due to the retention of hot air. The walls of the hood are heated evenly, with one or several heat sources located underneath. The limited cavity creates a "view" effect.

The designer, in the process of experimental research, improved the furnace of the stove, modernized the heat supply process, and changed the type of equipment. As a result, the device was perfected, the oven has high reliability, quality, and is distinguished by its impeccable appearance.

Double bell oven

More often, there are models where two hollow containers are provided. At the bottom of the furnace there is a chamber with a high temperature for the final combustion of gases, which are divided into cooled and hot ones. The first ones are discharged into the pipe, the heated ones are retained in the bell, while the heat exchanger is not cooled.

After kindling, the red-hot smoke rises under the arch, where it remains until it cools. The fuel burns out, new heated portions, rising, displace those that have already cooled. The cooled mass enters a vertical channel that leads them to the upper dome. The cooling and displacement situation is repeated in the upper cavity, but the used smoke is already discharged into the chimney.

Protection against condensation on the walls of the smoke channel is required, since cold air passes through them, which has given heat to the masonry. Chimney insulation is used.

Heating and cooking option

Complex aggregates are popular for their extended functionality. Despite multitasking, such devices work on the principle of distributing hot air to different streams. The design has not only a cooking surface, but also a built-in oven for baking. You can cook and bake a short time after kindling. Above the niche where the cooking stove stands, they arrange shelves for drying.

The hood accepts and removes gases from its bottom. Leaving the valve open will not affect the heating efficiency, since the air stays in the cavity for a long time and releases energy. Waste after combustion flows out of the oven without hindrance. Such a device is effective if there is little room for a tall pipe.

Device characteristics

There are no narrow channels in the structure, the bell-type stove is distinguished by less resistance to the heated flow, therefore the chimneys are made shorter.

Reasons for efficiency:

- two hoods promote uniform heating of gas and brick surfaces;

- hot smoke is retained for a long time, which gives the greatest heating, accumulates heat;

- collecting products from fuel burnout in one place reduces the likelihood of soot in the chimney.

The water heat exchanger is placed in the bell, therefore, the furnace productivity increases, and the efficiency increases. It is not so easy to build a two-bell structure in compliance with all norms, the master must follow the order for the Kuznetsov furnace and lay bricks strictly according to the plan of each row.

How to fold the stove I. V. Kuznetsov

It is better to plan the foundation of the stove during the design period of the house. The dimensions of the foundation must exceed the dimensions of the furnace by 15 cm on each side; it is not associated with the base of the residential building.

If the heat source is placed along the wall, the stove foundation is removed from the foundation of the house by 6 cm, and a gap is made between them, covered with sand. The concrete structure is isolated from soil moisture with roll materials.

The brick is also laid on a three-layer insulation with roofing felt. Consider the location of the chimney so that the safety conditions inside the room, when passing through the ceiling and when installed on the roof, are observed.

Heating is tested one day after the end of the laying.

Calculation of dome heating devices

Design includes methods for selecting internal fittings and equipment to obtain effective thrust, increase heat transfer without loss. The heat loss of the room is calculated by volume, then the resulting value is multiplied by 21. This is the average loss for 1 cubic meter. The stove power must be 15% higher

If the projects do not suit the user, he can make the project on his own, taking as a basis the general rules for the construction of bell structures. Determines the outer dimensions of the heating structure, divides the result by 300. The number means the heat output that the square of the outer wall of the stove can give off. Get the required squaring of the walls above the grates.

Performance indicators of the bell method

Stoves need to be heated twice a day in order to create a comfortable microclimate in the room. The average consumption of logs for heating 100 squares of area is 16 - 17 kg per day. Skeptics argue that long-term retention of smoke leads to a weakening of the draft in the chimney, but this is not the case:

- Smoke vacuum in the bell cavity shows a value of 0.18 hPa, which is considered a normal indicator in relation to atmospheric pressure and creates conditions for natural convection.

- The open door of the blower chamber helps to seal air, which is used to replace the rarefied flows in the bell.

- The smoke exhaust pipe is a pipe for exhaust gases, thanks to the adjusted length, it provides a high speed of movement.

The hood is placed behind the combustion chamber, because of this, the heated smoke immediately moves into it, without cooling in a short passage.

Furnace designs for low-rise buildings

Most often, heating stoves are used to heat the house. They are combined with a stove for cooking hot food and an oven for baking bread.

There are sauna varieties that heat the steam room, dressing room and washing room.

Street options are made in the form of a complex with a barbecue, grill, cauldron for cooking in an open space.

The rooms are represented by fireplace stoves and separate open hearths. They are used to raise the temperature in a room and as a decorative element.

Order scheme and materials for construction

Refractory fireclay bricks are used, which are placed on a clay mortar. It is not recommended to use the usual cement-sand mixture. You can not take silicate brick for masonry.

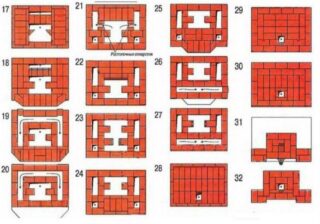

On the first row, angles are set, and from the second they begin to make smoke channels, form a blower and an ash pan. The brick is laid in a checkerboard pattern, the seam is 6 mm. Set the inner walls to a height of three rows.

Grates are placed from the 5th row, making gaps of 7 mm to the walls. Stove doors are installed, the combustion chamber is trimmed with fireclay bricks. Up to the 16th row, the laying is carried out similarly to the previous scheme, and from the 17th row, the cavity of the cap is formed, then the second compartment is equipped above the first.

From 21 rows, they put an overlap over the caps, make passages along the walls on two sides. The work is carried out according to the ordering scheme up to row 26, then the top of the cap is covered with brickwork.

Such stoves were laid long ago without Kuznetsov. Whoever has folded the stove can write his last name on it.