The construction of a frame house resembles a designer. The construction of a wooden building is carried out according to the scheme. The reliability and strength of the future structure depends on the quality of the assembly of the units of the frame house.

Structural features of a frame house

The strapping of a frame house is a connecting element of a structure on a columnar or pile foundation. The lower nodes connect the parts of the base structure between the uprights and the walls. The top rail acts as a unifying system for the partitions and also distributes the load from the roof.

There are two categories of nodes for timber frame houses.

Main nodes:

- wall system;

- floors (ceilings and floors);

- roofing system.

Auxiliary nodes:

- connections of various parts;

- fastenings and places of joining of jumpers.

For some types of buildings, no piping is needed. For example, if the building has a small area, and the height of the piles from the ground is less than 0.5 m. The strapping is optional when the house is being built on a monolithic strip foundation. But if the building has 2 or more floors, as well as a complex structure, connecting elements must be present.

Purchase boards and beams of coniferous trees, since they have optimal performance characteristics.

Connection nodes

The purpose of the strapping is to strengthen the frame, connect the roof and foundation, and also give strength to the structure. The lower and upper assemblies perform different tasks, but they have the same assembly principle. Auxiliary elements that need to be given equal attention are the corners of the wall and the building system.

Bottom strapping

The system is designed to strengthen the building at the bottom. The harness distributes the load evenly around the perimeter. It is the same integral part of the base as the grillage. In this case, the technology of manufacturing the foundation does not matter - fasteners are used in all cases.

The nuances of the top strapping

It is mounted on vertical supports after fixing the corner posts. When the length of the building is more than 6 m, intermediate pillars are installed in the center of the wall. After these works, the upper harness is laid and the jibs are fixed. This is followed by the installation of the remaining uprights. Upon completion, the temporary supports are removed.

If using a bundle of planks, stagger them together using nails of different lengths.

Wall corner and building system

Corner joints of a frame house are places of maximum heat loss. It is in these areas that condensate accumulates. Warming the corners is a priority goal, therefore, when assembling the frame, it is necessary to carry out appropriate work.

The formation of the wall corner is carried out according to the following scheme:

- place the fixing strips on the outside of the vertical beam;

- place the corners on the side;

- fix the connections.

In addition to corners in the building system, there are types of fasteners:

- In the upper harness, it is necessary to connect the ceilings, beds, racks on the pediments.

- Fastening of internal racks to the rafter and to the ridge.

- Tying struts (rafter supports).

- Crossbar fasteners to inclined rafters.

- Knots for battens.

The elements are fastened with corners or nails, if the parts of the system are superimposed on each other.

The boards used for strapping must be even and of the same size. Standard parameters: 380x1400 cm or 380x1000 cm.

Node design

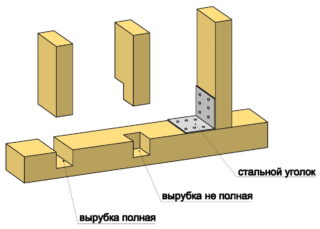

In the structure of the frame house, vertical posts are provided, which are mounted on top of the lower strapping. Nails act as connecting elements. Metal corners are used to fasten T-shaped beams without punching. Fixation with nails is used at the junction with the partial cutting of the lower beam - this is the most difficult stage in the self-erection of a wooden building.

Start laying the strapping by marking the corners, according to the sketches.

A joint without punching is relevant for corner joints of supports. Butt-type fasteners with plate fixing are used on the main elements of the house in construction. Craftsmen use fasteners with a partial cut. This method prevents the lumber from moving when drying out.

The volume of cutting for the vertical structure pillar should not be more than 30-45% of the thickness of the lower strapping beam.

In places where corner joints are not cut, fixation occurs with metal plates using self-tapping screws for wood. Perforated steel corners are used for reinforcement. It is recommended to choose self-tapping screws with a golden cap. To strengthen the corners, it is necessary to carry out technological processing - hardening - or use a metal with a cross section of 2 mm.

The cut-out mount is used to connect the uprights in the center of the wall. The recesses are prepared, supports are installed in them and fixed with nails. Reinforcement of the structure is carried out by installing vertical jibs, which rest against the rack with one side, and with the strapping on the other. For convenience, the ends of the boards are cut down, making them beveled.

Fastening elements

Anchors for wooden buildings are made of high-strength steel. The supporting elements are held together by reinforced corners. Fasteners are used from hardened steel or 3-4 mm thick. Fixation of minor parts is carried out with ordinary corners of 2-3 mm.

In timber frame houses, the following are used as fasteners:

- Smooth perforated plates and corners. The connection of the nodes is carried out using self-tapping screws for wood.

- Straight and angle brackets - wire elements of different diameters. The edges are folded over and inserted into the end or side of the beam.

- Bolts are used to tighten adjacent nodes, such as rafters. They are inserted into through holes and tightened with nuts.

- Traditional fasteners are nails.

Waterproofing is an important step in the construction of a wooden house. Spread roofing material on the concrete surface or apply mastic to the surface. After installing waterproofing materials, check the horizon. Deviations of no more than 0.5 ° per 3 m are allowed.

Common node connection errors

The drawing of nodal connections assumes that the developer or owner has sketches with a description of the structure. Despite the technical documentation, novice builders often make annoying mistakes.

A common mistake is not placing pillars or piles in a line. A similar defect is revealed at the stage of installing the foundation. With such a miss, not all walls will rest on piles, since the strapping will not take place according to technology. Elimination of the error will require financial investments and the involvement of experts.

In view of this, at the stage of arranging the foundation of a wooden frame house, take into account the geometry of the future object. Mark accurately, accurately and refer to technical documents.

Follow the recommendations of experts to improve the reliability of your future home:

- Install insulating materials at the joints between the tree and the foundation, since cement has a negative effect on lumber.

- Check the accuracy of the trimming of the timber or board for construction several times.

- Fill the gaps with jute, foamed polyethylene or padding polyester.

- After each stage of assembling a frame house, check its geometry.

- Place the fasteners in increments of at least 1.5 m.

The construction of frame houses is a technology that is distinguished by its simplicity of execution. However, before erecting a building, it is necessary to take into account all the nuances and features. This will prevent mistakes and their negative consequences.

How many jambs are already .. horror ... what corners on the dowel need to be planted VERTICALLY .... And why will you fasten the lower harness? ... .. put tow or flax on the cuts ... ..yes !!!!!