Decking is a popular material used for construction and decoration of buildings. The main criteria for its selection are low weight, acceptable cost, high strength. When choosing corrugated board for the roof, you must first consider its characteristics and installation features. Not every type of the specified material is suitable for the organization of the roof.

Description and characteristics of the material

Choosing the right material requires consideration of wave height, stiffness, size, throughput, thickness, color and coating type. The duration of the product's operation depends on these qualities.

Profiled sheet is a material made from galvanized steel. Manufacturing method - cold rolling using a roll forming machine. The shape of the protrusions is wavy, square or trapezoidal.

Roofing sheeting has the following properties:

- The wave height exceeds 2 cm. The wave has a wider bottom, so the water flow is more efficient. The wave height should be higher if the roof slope is insignificant. In this case, during installation, an overlap of 1 wave is provided.

- The presence of a capillary groove. It prevents rain or melt water from entering the corrugated board. However, with an incorrectly selected wave height, this element will not save from fluid flowing under the roof.

- Dimensions. Average material characteristics: length - 0.5-12 m, thickness 0.4-0.8 mm (optimal indicator 0.45-0.5 mm), width - 1 m.The wave height ranges from 2-7.5 cm. Weight of 1 m² of material ranges from 5.14 to 12.87 kg.

- Coating. An unpainted type of material is used in the construction of outbuildings or for the temporary organization of the roof. Painted sheets are more reliably protected from the influence of external negative factors and will last longer. There are such types of sheet coating: glossy or matte polyester, pural, plastoizol, polydifluorionad.

The color of the roofing sheet does not determine its technical qualities, but the general appearance of the structure, its compatibility with other objects on the construction site, depends on it. When choosing, take into account the influence of direct sunlight on the material. The color fades and fades over time.

A roof made of corrugated board is characterized by: high strength, reliability and long service life. A wide range of colors of material, various textures are available to the buyer. Fastening of sheets can be done independently. The small mass of products allows them to be used to cover houses on soft soils, since they slightly make the structure heavier.

The disadvantages of the profiled sheet include the "drum" effect when it rains. Eliminate the problem with quality sound insulation. Another disadvantage is the appearance of rust in places where the protective layer has been mechanically damaged.

Varieties of corrugated board

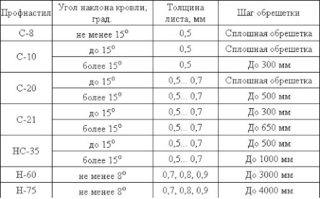

For arranging the roof, different types of material are selected. Each of them meets certain characteristics suitable for roofing material:

- C8. The sheet has a wavy surface. Its strength is not very high, so it is better to use it for temporary coverage. This type of product is suitable for roofing with solid sheathing. It has a relatively low weight (4.5 kg) and thickness (up to 0.7 mm).

- C10. The corrugation has a trapezoidal shape.Suitable for arranging roofs on roofs with a large slope. Recommend material for covering outbuildings. The maximum pitch of the lathing is 0.8 m. Depending on the thickness of the sheet, its weight is 4.6-7.6 kg.

- Roofing professional sheet C18. The product has a wavy or ribbed surface. Suitable for roofs with a slope not exceeding 25 degrees, and a batten pitch of 40 cm. The material is easy to process and install.

- C44. Such a profiled sheet is characterized by a trapezoidal shape and a large wave height. A polymer layer is used to protect the product. It has increased rigidity, so it can be laid on the roof, even if the step between the elements of the lathing reaches 2 m. In this case, the structure can be either gable or flat.

- HC35. The material is equipped with an additional ribbed surface, which makes it as strong and rigid as possible. The roof is airtight. In this case, the step of the lathing should not exceed 1.5 m.

- Professional sheet for the roof Н57. Sheet with trapezoidal corrugation. It has a characteristic high wave. The advantage of the material is the presence of a groove on the corrugation. The product is durable and suitable for roofs with battens up to 3 m.

- H75. It has maximum strength characteristics, as it is equipped with additional stiffeners. The surface of the sheet is trapezoidal with a maximum profile height.

The strongest profile is grade Н114-600, since the product has several additional stiffeners. The material can withstand high loads, so it can be used in harsh climatic conditions.

Roofing device made of corrugated board

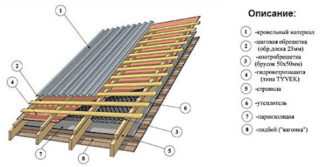

The roof consists of several layers that must be installed in a strict sequence. This ensures reliable protection and thermal insulation of the entire house. The number of layers depends on the operating conditions and the purpose of the building. If it is intended for permanent residence of people, the standard roofing pie arrangement is as follows:

- lathing;

- vapor barrier layer;

- counter lattice;

- heat insulator;

- hydro-barrier;

- air gap;

- roofing material.

If the room is not residential, it is not necessary to put a vapor barrier and insulation. It is necessary to insulate ventilation shafts and chimneys.

Selection rules

In order for a roof made of corrugated board to serve for a long time and efficiently, the material must be chosen correctly. Main criteria:

- Metal thickness. For the roof, you need to use a durable material, as it lends itself to atmospheric influences. High-quality sheets have good bearing capacity, they can withstand the weight of a person who carries out repair or installation work. The optimum thickness is 0.5-10 mm. Thinner products can be installed in private houses, the rest are suitable for industrial facilities.

- Profile type. A material with a large wave height and additional stiffeners is suitable for the roof. Such products can withstand heavy loads and mechanical stress.

- The length of the element. For roofing from corrugated board, it is better to take sheets that correspond to the roof slope. The design in this case will look more aesthetically pleasing, and the installation becomes easier.

- Compliance of the professional flooring with the norms of the state standard. All parameters are indicated on the package.

- Purpose. Do not cover the roof with wall material.

- Color. The range of products is extensive, but the effect of sunlight on the surface is taken into account. Darker garments run hotter and discolored areas are more visible.

An important selection factor is the coating of the material. It provides a beautiful appearance to the roof and has protective properties. When buying, you need to take into account the availability of quality certificates for the metal profile for the roof.

Necessary tools for the job

To put the profiled sheet on the roof correctly, you need to prepare the tools:

- a hacksaw for metal or other tools for cutting material;

- cord for marking the roof;

- hammer, rail;

- tape measure and building level;

- pliers for corrugation;

- knife for cutting sheets of thermal insulation;

- gun for fixing staples;

- screwdriver;

- drill with a set of drills.

When attaching the profiled sheet to the roof, you need to fasten the insurance on yourself so as not to fall from a height. It is necessary to work in protective clothing and gloves.

DIY installation features

Before covering the roof with tiles or other material, it is necessary to calculate how much material is required. First you need to measure the base along the ridge, and also determine the length of the slope. Next, the wizard calculates the horizontal rows. For this, the width of the ramp is divided by the width of the corrugated board element. The resulting figure is rounded up.

To find out the number of sheets in one row, the length of the slope is required. The size of the overlaps and the dimensions of the sheets are also taken into account. Before laying the sheets, the structure is being prepared.

Since the corrugated board is made of metal, condensation may appear on its surface during operation. The liquid negatively affects the rafter system and the sheets themselves, therefore waterproofing is required. The material must be laid on the rafters and fixed with a construction stapler. Lay the film so that there are no folds or damage on it. The pieces of insulation are overlapped and connected with tape.

On top of the waterproofing layer, wooden blocks are attached to the rafters. Nailed them in a row, observing the distance between the elements (5-10 cm).

Further, the work includes the following stages:

- Arrangement of the lathing. Fastened perpendicular to the already prepared bars. It is the basis for laying roofing material. Wooden elements are impregnated with a composition that protects them from biological factors and fire. The pitch of the lathing ranges from 0.3-1 m. The optimal value is 0.5-0.6 m.

- Roofing device made of profiled sheets on wooden lathing. For fixing the sheets, galvanized self-tapping screws are used, equipped with a neoprene washer. This rubber will prevent moisture seepage. The self-tapping screw is placed at the bottom of the wave. Place the clips in a checkerboard pattern. Correct installation of the first row of corrugated board involves screwing self-tapping screws into each wave. The material should fit as tightly as possible to the base. Before laying the first row, a cornice bar is installed. The overhang of the roof at the edge is 5-30 cm. The higher the wave height, the greater this indicator.

- Installation of subsequent rows. The technology provides for compliance with horizontal and vertical overlap. The steeper the slope, the smaller it is, since the liquid will quickly and easily drain from the roof without getting under the roof. If the length of the structure and the sheets are the same, before screwing, the material is aligned in relation to the eaves line. If the material is adjacent to the wall, an angle bar is attached at this place.

- Installation of additional elements. The wind strips are laid from the bottom up. Screw in the fasteners every 30 cm. In this case, do not forget about the overlap. The upper part of the plank should overlap the first row of corrugated board. The ridge elements are mounted with an overlap of 20 cm. A seal is laid under these products. Long screws are required to attach the ridge.

Last of all, the snow holders are fixed.

If you follow the step-by-step instructions, the installation of the roof will not cause problems. You also need to take into account the following recommendations:

- you need to cover the house with corrugated board so that the sheets lie against the prevailing wind direction in the area;

- the laying of the material begins from the end of the roofing structure, if the sheet fits on the slope along the entire length;

- you need to align the elements along the cornice;

- the joints between the sheets are strengthened with hardware, and not only on the wave, but also on the deflection;

- electric scissors are used to remove excess corrugated board;

- it is forbidden to use abrasive cutting elements for cutting the material, as they damage the protective layer and the metal begins to rust;

- it is possible to correctly calculate the amount of corrugated board only taking into account the useful width of the sheet (element size minus overlap allowances);

- so that there is no gap between the joints, the wider shelf is located at the bottom, and the narrow one at the top.

The fasteners must be tightened strictly at right angles. Otherwise, the gasket will not fit snugly to the base, water will flow under it.

When calculating the amount of material, both slopes are measured, since the rafter system is not always perfect.

Forgot about the wind rose in this region. You need to start laying the sheets from the side of the roof where the prevailing winds blow, otherwise it will really blow off the roof (in a strong wind)!

I wanted to cover the roof, but one person dissuaded it, saying that there was such a roar in the rain, at least take out the saints.

GALTURA !!!!! I used simple acrylic on the crate! does not rattle does not knock! and the crate does not rot from condensation !!! the sixth year is worth anything. during installation, use a ladder so that the prof. sheet falls into the streams.