Many private developers prefer to make houses and outbuildings on the site using a frame method or from lightweight and practical foam concrete blocks. The latter have one very significant drawback - the unpresentable surface of the outer walls. One of the best solutions is to clad the house with imitation of a bar. The finished building looks like a solid mansion built from a real solid wood. The technology is universal, it can be applied from the outside and from the inside, with a competent approach to the matter, it is quite feasible with your own hands.

What is imitation timber

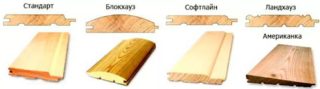

Timber imitation belongs to the category of cladding finishing materials applied to the base without the use of adhesives. By its design, it is a rail, the front part of which is turned to match the massive or glued timber used in construction. The surface has a flat or semicircular texture with characteristic grooves along the top and bottom edges. The connection of the strips is made into groove locks, which contributes to the achievement of solidity and the absence of through slots in the coating.

The cladding presented in the retail network has the following parameters:

- thickness - 16-32 mm;

- height - 10-20 cm;

- length - 300-600 cm.

The following types of wood are used as raw materials for the manufacture of panels:

- Pine;

- cedar;

- oak;

- spruce;

- Linden;

- larch;

- aspen.

Decorating the house from the outside under the timber can be carried out on walls made of almost any materials, the degree of shrinkage of which does not exceed this indicator for decorative lining.

Material advantages

The decision to sheathe the house with imitation timber is beneficial in many ways, even when the presentability of the building is not of particular importance.

The material has the following advantages:

- Affordable cost, which largely depends on the value of the wood used.

- Nice looking appearance. The finish looks great in any interior and exterior interior.

- Easy to install slats. All the details are thought out, the master is not required to show ingenuity and make complex non-standard decisions.

- The ability to decorate buildings at any time of the year. There are no wet works. The only limitation is precipitation.

- Installation variability. Mounting can be carried out on the frame and directly on the wall. In the first case, using the available space, the master can carry out additional insulation of the building.

- The use of the glue method for the production of planks ensures the constancy of their shapes and sizes.

- Excellent heat and sound insulation characteristics. Timber finishing inside the house maintains an optimal balance of indoor humidity.

It is advisable to use wide slats for external work in order to create the illusion of using expensive massive links. Inside, it is better to sheathe the house with narrow slats in order to visually increase the size of the walls and ceilings.

Material selection rules

Initially, you need to make a choice regarding the shape of the rails. They are even with bevels along the edges and convex curved. The first option is cheaper, but the second looks more spectacular and more comfortable.

The next criterion is the type of wood. Spruce and pine are light, light shade and affordable. The material exudes a pleasant smell, the substances it secretes are a natural antiseptic that is useful for the respiratory system.At the same time, these species are hygroscopic, prone to drying out, rotting and tangible changes in size with fluctuations in humidity.

Cedar, larch and oak are immune to environmental influences, and from contact with moisture they only become stronger. However, their cost may turn out to be unaffordable for many developers, and a high specific weight will require the creation of a powerful lathing and possible strengthening of the foundation.

Next, you should pay attention to the class of raw materials. Products of the Premium and A category are distinguished by a uniform color, no or minimal amount of knots and surface cracks. Products of class B and C contain a large number of knots, including dropping out, shallow and deep through cracks. Expensive planks do not require additional processing, while it will take time and money to bring low-grade raw materials to the desired condition.

It is necessary to check the condition of the panels when purchasing them. They should not have chips, dents, cracks, tan marks or mold damage. Marking the front surface is not permissible, as the paint penetrates deep into the wood and is very difficult to remove.

Preparatory work

The first stage of finishing is drawing up a project. Measurements are made, the need for materials is determined, and its purchase is carried out. After delivery of the goods, it must be unpacked and kept for at least 5 days at the installation site, so that the slats acquire the parameters and humidity corresponding to the conditions of the forthcoming operation.

Then you need to prepare such a set of tools:

- roulette;

- a hammer;

- hacksaw;

- level;

- mallet;

- screwdriver;

- paint brush;

- ladder.

To prevent injury, gloves and goggles must be purchased.

The following materials will be required:

- wood for the lathing;

- self-tapping screws and plastic dowels;

- impregnation;

- antiseptic;

- topcoat (varnish, mastic, stain, paint).

Before sheathing, all objects are removed from the walls - wires, lamps, plates. Nails and screws are pulled out. The surface is leveled, treated with an antiseptic and a primer.

Stages of cladding a house with your own hands

In order to properly decorate a house with an imitation of a bar, it is necessary to perform a number of sequential activities, each of which has a targeted focus.

Stages of cladding a building with decorative slats:

- Vapor barrier. Glassine, waterproofing or similar materials are used. Fastening is carried out with vertical stripes, joints and breaks are glued with tape.

- Lathing. A bar is used, the thickness corresponding to the parameters of the insulation. Based on this indicator, the interval between the racks is also taken. Without insulation, the maximum step is 100 cm, and the minimum timber thickness is 3 cm. The planks are fastened in a horizontal orientation.

- Warming. Choose from polystyrene, mineral wool or polyurethane foam. Fastening is carried out with dowels, twine or wire.

- Wind protection. Designed to isolate insulation and walls from environmental influences. An excellent option is isospan, which is nailed to the crate with furniture staples.

- Counter battens. The design is designed to create effective ventilation of the filler. The timber is placed in an upright position at intervals of no more than 50 cm to prevent deformation of the cladding.

- Installation of imitation. The starting rail is placed at the bottom with a groove downward and screwed to the counter batten. Clips can be another option for fastening. The connection is made until full contact between the strips is achieved. The last element is trimmed, the corners are closed with profiles.

The final stage is the processing of the finished surface. It is cleaned of irregularities, after which it is covered with an antiseptic, and last of all with a waterproof protective coating.