The requirements for the exterior walls of the house vary from functionality to appearance. Most of the problems of old houses and new buildings made of various materials will help to solve the house cladding with metal siding. It is necessary to familiarize yourself with the assortment of finishing materials and the nuances of working with it.

Purpose, advantages and disadvantages of the material

Metal siding is widely used in building facades, roofs and fences.

The popularity is due to the ease of installation, the ability to use in any climate, and high consumer properties.

Among the advantages are:

- long service life, with a manufacturer's guarantee for perforating corrosion up to 50 years;

- various designs, allowing you to select products for any exterior of buildings;

- the ability to maintain a single style throughout the entire complex of home ownership - walls, roof, fence, outbuildings;

- ease of preparation of the base and speed of installation;

- a wide range of operating temperatures (from -60 to + 80 ° C) at which the characteristics are preserved, there is no damage to the appearance;

- minimal maintenance during operation;

- fire safety;

- the ability to order panels of any size at the price of standard elements;

- resistance to mechanical damage and abrasion;

Cladding with siding allows you to transform the appearance of old brick and wooden buildings, as well as to complete the finishing of new houses, saving on plaster and wind protection.

At the same time, the metal has limitations in use, since the iron cladding has disadvantages:

- high price compared to other types of finishes;

- houses need thermal insulation, since steel has a high thermal conductivity;

- a large mass of siding is taken into account when calculating the foundation, walls, lathing, which increases the cost of construction;

- repair of damaged panels is impossible - you will have to install new elements;

- during installation, care must be taken - violation of the protective layer provokes the rapid spread of corrosion.

The decision to sheathe the house with metal siding is taken, taking into account all the positive and negative aspects of the material.

Varieties of metal siding

Most manufacturers manufacture panels according to their own specifications. Products are classified according to several criteria:

- used raw materials;

- appointment;

- protective coating;

- structures - type of profile and geometric dimensions;

- installation method.

These parameters are important for choosing the right exterior cladding for the house.

Raw materials

Use:

- sheet galvanized steel with continuous lines;

- hot-dip galvanized sheet metal;

- thin-sheet cold-rolled and cold-rolled hot-dip galvanized steel with polymer coating;

- thin-sheet rolled products with protective and decorative paint and varnish or polymer coating;

- steel rolled products with polymer coating;

- rolled aluminum.

The choice is made based on the operating conditions, there are no significant differences depending on the type of rolled steel.

Aluminum sheets have less stress on the foundation and walls. Aluminum does not corrode. The main reason for the low popularity is the high price, which is 1.5–3 times higher than the cost of steel products.

Appointment

Manufacturers and sellers distinguish three types of panels, depending on the purpose: facade, basement and perforated.

Facade products are needed for wall decoration. It is permissible to use them for the base, but the service life from contact with the ground and from the constant influence of flowing water is sharply reduced.

For basement siding, the thickest metal is used, which resists corrosion for a long time.

Perforated sheets are used for finishing the space from the wall to the roof overhang. This siding is also called soffit. The peculiarity is that air enters through thin openings under the roof, and the attic is ventilated. At the same time, condensation drops do not accumulate, flowing down through the perforations.

Protective covering

The protective coating includes several layers, which may differ in composition and properties.

In general, the metal on the front side is protected:

- zinc coated;

- primer;

- base coat with a printed pattern;

- transparent protection.

On the back side, there is no base layer and pattern, which is often replaced with a chrome-plated primer or other protection.

For protective painting, depending on the type of rental, use:

- polyester and polyurethane enamels;

- polyester-silicone and acryl-silicone enamels, organodispersed paints and PVC compounds;

- polyester, epoxy, polyurethane or acrylic powder paints;

- polyamide and polyvinyl chloride plastisols.

The quality of each coating must be confirmed by certificates of conformity. The paint is applied on automated lines, therefore, as a rule, no complaints are made about its quality.

When choosing, they are guided by the appearance and price of products.

Construction and geometry

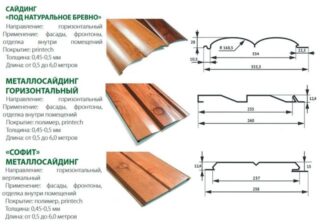

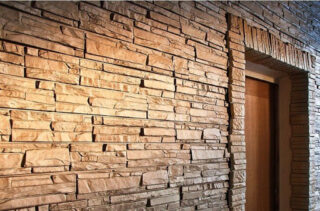

In appearance, they distinguish siding made in the form of a ship board, a block house and a wild stone. The names reflect the shape of the sheets.

"Wild stone" is often produced in the form of typesetting sheets of small height and length, so it is more convenient to finish the base.

A ship board imitates wooden planks or beams, and a block house imitates logs.

Mounting method

The method of fastening should be understood as the direction of the siding and the type of hardware.

The most widespread are panels for horizontal fastening. They imitate houses made of wood, especially when painted with a natural material.

The vertical arrangement of sheets is more often used in industrial construction or in some design solutions.

At the design stage, you should check with the seller (manufacturer) for which orientation in space a particular siding model is suitable. Models are not always universal due to the structure of the lock connection, which can lead to moisture penetration or destruction (deformation) from the load.

Important specifications

For the consumer, several specifications are critical.

The thickness of the metal affects the strength of the structure and resistance to external influences. The thicker the metal, the longer it will last. At the same time, the increased thickness has a great impact on the supporting structures.

For walls, choose siding from 0.4 mm, for a basement from 0.5 mm.

Orientation in space determines the location and configuration of the supporting crate.

Working dimensions are important when calculating the amount of material, so parts of the locking systems overlap and the total sheet size will be larger than the working one.

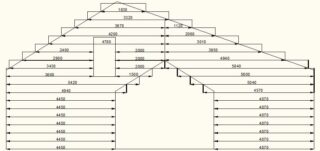

Material calculation

You can quickly and correctly calculate the amount of material for cladding the walls of a house using numerous online calculators.

It is necessary to accurately measure the height and length of each wall, the distance from the roof overhang to the wall and the height of the base, the dimensions of doors, windows, garage doors.

For installation, in addition to the siding itself, you will need additional elements, the type and number of which depends on the configuration of the walls of the building:

- racks of external and internal corners;

- chamfer or cornice panel;

- soffits - perforated panels;

- starting strip for the first sheet;

- docking profile;

- finishing pad;

- platband for finishing slopes;

- J-profile for joints at different angles;

- low tide, if the plinth protrudes beyond the wall and for windows.

Siding and additional elements are attached to blind rivets or self-tapping screws. Their number is from 3 to 4 per running meter of each element.

Check the calculations on several sites. Another way to get accurate data is to draw to scale the walls and the location of each structural element.

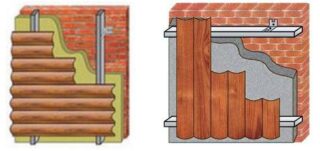

The lathing is made from a galvanized structural profile, less often from a wooden bar. Logs are placed every 50 cm. Large intervals reduce the strength of the entire structure.

Often, simultaneously with finishing the house with metal siding, walls are insulated with foam, expanded polystyrene or stone wool. In this case, they acquire the required amount of insulation and fasteners.

How to sheathe a house with metal siding

The step-by-step recommendations for installing panels look the same for any type of coating:

- Choose a material.

- Accurate measurements are taken, a detailed layout of the elements is drawn up.

- They buy siding, additional elements, lathing material, hardware.

- Clean the walls from dirt and dust. Wooden surfaces are freed from rotten areas, treated with an antiseptic against rot and fungus, impregnated with a fire retardant composition against combustion.

- They mount a lathing made of wood or a galvanized metal profile. On even walls, the logs are attached directly to the surface, with large differences, brackets are used.

- Insulation is laid, the joints are sealed with polyurethane foam.

- Attach additional elements. For ease of installation, the corners are often covered with simple overlay elements - this simplifies installation.

- The sheets are cut out after repeated measurements. For thermal expansion, gaps are provided, but not more than 10 mm, since the expansion of the metal with temperature fluctuations is insignificant.

- During installation, follow the manufacturer's instructions regarding the rules for connecting lock systems. Most often, the lower elements are first mounted, gradually rising to the roof.

- They trim the slopes of doors, windows, gates.

- Cover the roof canopies and overhangs.

It is not difficult to decorate a house with metal siding. Accurate calculation and accuracy during work will be required. Structural elements are available in any locality, if necessary, you can order parts according to individual dimensions, which will simplify installation. Siding will renew the walls of any house, protect building structures from destruction by weather conditions, which extends the life of houses.