The staircase in a building with multiple floors or a house with an attic must match the interior. However, reinforced concrete and metal structures often do not meet aesthetic standards. The same goes for a dilapidated tree. Finishing the stairs with laminate solves the problems of comfortable movement between floors and transforms the appearance of the room.

Advantages and disadvantages of laminate

Before you sheathe the stairs with a laminate with your own hands, you need to familiarize yourself with its features. The knowledge gained will help with the choice of material and will save you from mistakes during finishing work.

Laminate is a three-layer building material based on fiberboard. Due to its decorative appeal and physical properties when finishing floors and other elements of premises, it successfully competes with expensive wood and unreliable plastic. According to some parameters, the coating can be ranked among the leaders among finishing materials.

Laminate properties:

- resistance to mechanical stress;

- waterproofness;

- long-term preservation of appearance during intensive use (up to 10 years);

- ease of installation;

- a variety of colors and structures;

- ease of care;

- relatively low price.

The elastic coating has high sound-absorbing performance. A slightly rough or bulky surface prevents slipping, and a properly selected design brings warmth and comfort into the house.

Finishing steps with laminate is not devoid of negative sides:

- the need for a substrate;

- temperature and humidity expansion;

- damage from sharp objects.

Most of the negative reviews about laminated flooring are based on the use of cheap material of dubious origin.

Laminate selection rules

Comfort of use, service life and compatibility with the environment depend on the characteristics of the finishing material. When choosing a laminate for finishing stairs, the following parameters are taken into account:

- Strength and wear resistance. Since the steps are regularly subjected to increased loads, a commercial laminate is used as a cladding, which belongs to the 31-34 strength class.

- Lamella size. The complexity and speed of finishing, as well as reliability depends on this parameter. Ideally, laminated panels match or slightly exceed the tread and riser.

- Texture. For stairs as an object of increased danger, a material with a rough surface is suitable, which provides a confident fixation of the leg when going up and down.

- Design. In appearance, the laminate must match the surrounding interior decoration.

- Environmental Safety. Laminate class E1 (European standard EN 13329) is used in residential premises.

Cheap staircase laminate flooring quickly loses its original appearance and needs to be replaced. The purchase of a laminate from trusted manufacturers is accompanied by a 2 to 6 year warranty.

Preparatory work

Before finishing the stairs with laminate, it is necessary to prepare:

- checking the integrity and reliability of the steps;

- restoration, replacement of damaged and defective elements;

- removal of old coating, protruding objects and dirt;

- leveling surfaces;

- antiseptic treatment (for wooden stairs);

- anti-corrosion treatment (for metal surfaces).

Finishing a concrete staircase with a laminate is preceded by the restoration of steps using leveling mixtures followed by grinding. Decorating a metal staircase with your own hands begins with cleaning and installing a plywood backing, which will ensure reliable adhesion of materials.

Calculation of the amount of materials

To calculate the amount of materials used, it is enough to measure the area of the tread (horizontal surface) and riser (vertical surface) of one step and multiply it by the total number of steps. By a similar analogy, the area of the substrate, the number of sills and fasteners are calculated.

The finished panels must completely cover the cladding areas. Otherwise, the typesetting method is used, which reduces moisture insulation and reduces the strength of the structure.

Required tools and accessories

In order to sheathe the stairs with laminate in accordance with the established standards and not be distracted by the search for tools and materials, in addition to the laminate, substrate and sills, profile, before the procedure, you need to acquire:

- polyurethane or epoxy glue;

- self-tapping screws or liquid nails;

- electric or ordinary jigsaw;

- notched trowel;

- tape measure, level, corner;

- pencil.

Quality tools and binders will speed up your work.

Do-it-yourself laminate stairs

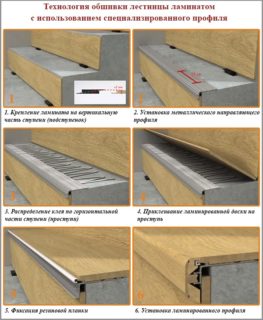

The correct laying of laminate on the steps depends on the type of profile used.

Specialized profile:

- The riser is evenly covered with glue, after which the panel corresponding to the marking is pressed against it with an indent along the lower edge by the thickness of the laminate. Support pads are installed in the gap, which hold the vertical board during fixation.

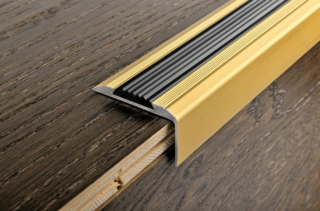

- A metal profile with glue applied to the reverse side is pressed against the edge of the step and is fastened from the vertical side with self-tapping screws, the distance between which does not exceed 15 cm.

- A corresponding board is applied and pressed to the tread, previously coated with glue, the edge of which fits into the groove between the tread and the horizontally installed laminate panel.

- The edge profile is equipped with a rubber insert that fits over the spike or fits into the groove.

- After filling the grooves with glue, the edge profile is placed on a metal guide without gaps.

The rest of the steps are faced in the same way.

L-shaped sills:

- Along the riser, using a notched trowel, evenly distribute the glue, after which the panel is pressed against it with an indent along the lower edge by the thickness of the laminate.

- After applying the glue, an appropriate lamella is applied to the above horizontal plane.

- At the point of contact between the vertical and horizontal panels, an L-shaped sill is installed, which is fixed with fasteners depending on the material of manufacture (metal - screws, plastic - glue, wood - by any convenient method).

A staircase properly sheathed with laminate is ready for use no earlier than in a day. If the lining was made exclusively with glue, the period is doubled.