Facing a house from corrugated board is an inexpensive and practical option for exterior decoration. The material is used for industrial and office buildings, private housing and outbuildings. Knowing the nuances of choosing and installing a metal profile, you can do the work yourself.

Description of corrugated board and selection rules

Profiled metal sheets are produced by cold rolling steel. As a result, a wavy profile is formed, which is a stiffening rib. The material is treated with anti-corrosion protection, it can have one or two-sided polymer coating. Profiled sheet is used in the construction of roofs, fences and other enclosing structures, facade decoration.

Metal profiles can be used to sheathe old buildings made of logs or beams, improving their appearance and increasing fire safety. The pluses of finishing include:

- durability;

- environmental friendliness;

- incombustibility;

- protection of walls from weathering;

- originality of the facade;

- the ability to do it yourself;

- affordable cost.

The disadvantage of metal sheets is noise, precipitation and wind make them make loud noises. Correct installation using soundproofing materials and reliable fasteners will eliminate the problem.

- galvanized - hot zinc coating prevents rust, the cheapest option, 15 years' service life;

- plastisol - a layer up to 200 microns thick can have an embossed structure, resistant to mechanical stress, the disadvantage is rapid fading, sensitivity to temperature changes;

- polyester - a polymer resistant to ultraviolet radiation, withstands a wide range of temperatures, due to its low price it is the most common coating option;

- pural - the coating is not afraid of corrosion and sunlight, a wide range of colors is offered, glossy or matte surface;

- PVDF coating - the composition is resistant to any weather influences and mechanical damage, does not change the color intensity.

The type of coating determines the duration of the finish. With proper installation, the corrugated board with a polymer layer will last at least 50 years. The decorative protective coating is applied on one or both sides. You can sheathe the house with products with external staining, the second side will be hidden. Such sheets will be cheaper. Also, when choosing a facing material, the dimensions of the sheets are taken into account: thickness, length, width.

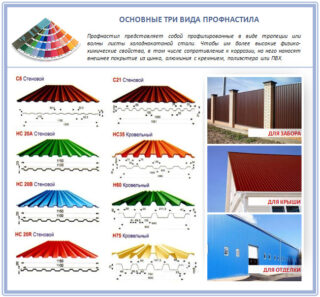

Varieties of corrugated board

- "C" - wall corrugated board is characterized by low bearing capacity and profile height. It is recommended for finishing facades, building fences and barriers. The height of the corrugation is 8-21 mm. Sheathing of the house with corrugated board is carried out with products marked C8, C10, C15, C20. The sheets are strong enough and lightweight.

- "N" - bearing profiled sheet designed for installation of loaded structures: fixed formwork, flat roof.

- "NS" - a universal, load-bearing corrugated wall sheet can be used to cover the roof, install fences, wall cladding. Products have additional stiffeners.

Wall metal profile C8 is an economical cladding option.It has sufficient strength, has a wide range of polymer coating colors. Sheets of grade C10 received a trapezoidal waveform and a thickness of 0.4-0.5 mm. For facades, products with wood, stone or brick decor are produced. C15 corrugated board is distinguished by a wide wave and a large installation area. The weight of the products depends on the thickness of the material, which is 0.45-0.7 mm. The use of profiled sheets with a high wave, which are heavy, will create an undesirable additional load on the foundation.

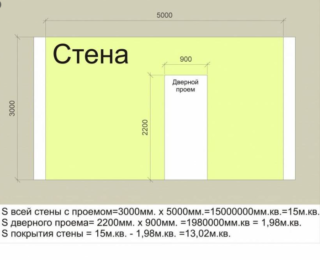

Calculation of the required amount of material

In addition to the facing material, additional elements will be required:

- outer and inner corner;

- basement, docking, slope strip;

- window sills.

The value of the facade area will help to calculate the amount of insulation that will be required during installation. When calculating, 10-15% of the material is laid for trimming.

Required tools and materials

For work, you will need a hand and electric tool:

- hammer drill or drill with a set of drills;

- screwdriver;

- a hammer;

- scissors for metal;

- construction plumb line;

- bubble or laser level;

- tape measure and pencil.

In addition to corrugated board and additional elements, you will have to purchase: a metal profile and suspensions, a primer, mineral wool, self-tapping screws and dowels, paronite gaskets, a vapor barrier film. For installation work, you will need a ladder or scaffolding, protective gloves.

Do-it-yourself house cladding with corrugated board

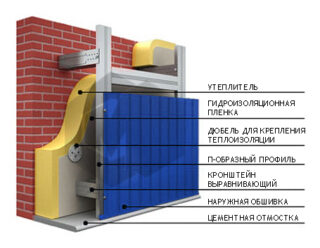

Before sheathe the house with a wall profiled sheet with your own hands, you need to study the technology of the ventilated facade device. It involves the installation of the frame, insulation of the structure, waterproofing, sheathing with profiled sheets. An air gap remains between the finishing material and the thermal insulation. It is necessary to drain excess moisture, prevent the accumulation of condensation, mold formation. Stages of work:

Preparation

Finishing a house with a metal profile begins with preparing the surface of the walls. All existing elements are removed from them: the drainage system, platbands, ebbs, lamps and more. The old finish is removed completely. A revision of the walls is carried out, the cracks found are sealed with cement mortar, in wooden houses with a special putty. The surface is thoroughly cleaned of dust and dirt, then treated with an antiseptic primer. The impregnation is applied in two layers. Such protection is mandatory for wooden buildings.

Markup

Horizontal and vertical skips are performed using a plumb line, laser or bubble level. The axes are outlined, which will serve as a reference point for subsequent marking. On the walls, using a tape measure, the attachment points for the hangers for the guide profile are determined. The distance between the marks is equal to the pitch of the lathing. The place of installation of the profile around the openings is separately marked.

Mounting brackets

According to the markings, a hole is drilled in the wall with a perforator up to 100 mm for fastening the brackets. Each requires 1-2 plastic dowels with self-tapping screws. A paronite gasket is placed under the bracket to prevent the formation of cold bridges. Parts must be securely fixed, their location in the same plane is checked by a level.

Assembling the frame

You can decorate the walls by fixing the profiled sheet horizontally or vertically. The features of the frame installation depend on the chosen method.The guides are installed perpendicular to the finish. The lathing for the corrugated board is assembled from a metal profile of various configurations or wooden blocks. In the second case, the material must be impregnated with an antiseptic. The vertical profile is attached to the brackets with self-tapping screws. To strengthen the rigidity of the frame, horizontal jumpers are made.

Warming

Rigid basalt slabs or expanded polystyrene are used as insulation. Mineral wool insulators are preferable, they ensure the vapor permeability of the walls, do not burn, do not deform over time. The thermal insulation fits tightly between the guides. For fixing, 5 disc dowels with a wide head are required - 4 are installed at the edges, 1 in the center. The foam is fixed to the wall with an adhesive solution. A wind and vapor barrier film is attached on top of the thermal insulation. The canvases are laid with an overlap of 10-20 mm, glued together with construction tape. The material protects the insulation from blowing moisture. The film is attached to the frame with self-tapping screws.

Installation of corrugated board

The corrugated board is cut to size. Special scissors are used to cut metal sheets. Work faster with a grinder, but the use leads to a violation of the polymer coating and subsequent corrosion. The metal profile is fastened with self-tapping screws selected in the color of the polymer coating. The sheets are installed with an overlap in one wave, the installation starts from the corner of the house. Each panel is leveled and screwed in 1-2 wave increments. At the junction of the profiled sheets, the overlap is fixed with self-tapping screws with a pitch of 50 cm. All self-tapping screws must be located on the same line. All walls of the building need to be finished using this technology.

Facing the pediment

Before sheathing the space under the roof, a drawing and an accurate calculation of the material are performed. Profiled sheets are trimmed to the desired shape. A frame is assembled from a bar or a metal profile. The pediment is insulated before finishing installation. To fix the sheets, an ebb is installed in the lower part of the structure, and a finishing strip under the roof. The corrugated board is attached to the lathing in the same way as the material on the walls.

Sheathing the house with sheathing extends the service life of the building, protecting the walls from negative influences. A variety of modern options for polymer coating allows you to give the facade an original look with minimal financial costs.