Decorating a concrete staircase with wood is a rather time-consuming procedure. But if you study the installation technology, carefully prepare the surface and all the necessary tools, you can deal with it yourself.

Choice of wood

Concrete stairs are reliable and durable, capable of withstanding heavy loads. The main drawback is the unaesthetic appearance. Other disadvantages include lack of comfort in operation and low thermal efficiency. To eliminate all these shortcomings, they carry out finishing (facing, sheathing) of concrete stairs with wood.

Finishing is possible from any wood species. Larch, oak, beech, pine, walnut and ash are usually chosen. Each of them has its own characteristics and performance characteristics.

The main criteria that you need to pay attention to when choosing wood for finishing a concrete staircase are the hardness, strength of the tree, its durability and resistance to decay processes, the color range, and the price.

Larch

It has medium hardness and wear resistance. The material is almost not subject to decay, but there may be resin inclusions on the surface, which complicate the finishing process. The choice of shades is large, the cost is average.

Oak

The material is of the highest quality, strong and durable. Oak has a rich texture and interesting color. The wood is not susceptible to decay, mold and pests. Due to its positive properties, it is the best finishing material, but it has a high cost.

Beech

It has a beautiful beige-pink hue and is practically not inferior to oak in hardness. By its nature, beech is not able to withstand water and steam, therefore it is not recommended to use it in rooms with high humidity.

Ash

It has a nice texture and has a gray-yellow tint. Ash wood is the most durable and is distinguished by its durability and high resistance to mechanical stress, but does not tolerate moisture. For protection from moisture, painting with special agents is required.

You can also use a cheaper material such as pine to create the steps. This coniferous species is affordable, but due to its low strength, steps from it quickly wear out and lose their appearance.

Advantages and disadvantages of wood cladding

Decorating a concrete staircase with wood has many more advantages than disadvantages:

- wood cladding will give the concrete structure a beautiful appearance;

- increases comfort and coziness in the house;

- allows you to create a variety of finishes;

- wooden coatings do not emit harmful substances and are environmentally friendly;

- will allow you to level out all the unevenness of the concrete;

- wood retains heat better than concrete; it is pleasant to walk on it barefoot;

- it is possible to easily repair or replace the cladding without replacing the entire structure;

- the wood can be repainted and the shade of the wood veneer updated.

Disadvantages:

- wood is a combustible material;

- some types of wood are afraid of moisture.

These disadvantages can be dealt with by using moisture-resistant wood species, for example, larch or oak, for cladding, and impregnating the wood with a fire retardant for fire protection.

Substrate preparation and cladding methods

To finish the stairs with wood, you must first prepare the base. All defects and irregularities must be eliminated near a concrete staircase. With the help of a grinder, the steps are leveled, cleaned of dust and treated with a primer. After complete drying, all cracks and depressions must be repaired with a putty and the surface of each step must be leveled with a spatula.

After the preparation of the concrete base, the timber cladding elements are installed. There are several ways.

Plywood pre-cladding

With this method, wooden steps are installed on a plywood panel, which is used as a backing. It is better to sheathe the entire surface of a concrete staircase with plywood, then the structure will turn out to be more solid and durable. Installation should be started from the bottom step of the concrete staircase.

First of all, you need to check the steps of the stairs for horizontal level. Deviations should be minimal in all directions. Then, using a jigsaw, you need to prepare plywood panels. Next, the panels are attached to the riser dowels, after which the plywood is mounted on the tread. After laying all the plywood panels on concrete, a false bowstring is attached to liquid nails, which can be purchased or made. This is a supporting element of the staircase made of a wall board, which protects the wall from dirt.

Then you can start plating the steps with wood. Wooden elements only need to be glued if the surface of the stairs is completely finished with plywood.

Cladding with preliminary sheathing with plywood is a time consuming and costly method, but it is considered the best, since it significantly increases the quality and service life of the stairs.

Facing with metal fasteners

This cladding method is performed without plywood using metal fasteners and glue. First, the surface of the concrete staircase must be leveled. Then fix and install the upper tread, wedge and install the riser. Then, with precise fixation and marking of all elements, lay the next step. To mark the fastener points, you need to use metal corners. After fixing and installing the tread and riser, they must be removed, assembled with self-tapping screws into a single structure and the corner must be screwed to the step. Concrete steps and risers are then covered with glue, polyurethane foam. The structure is installed in place. It must be fixed with corners, and the risers with plastic dowels.

Chemical anchors

This is a simplified cladding method that does not use a plywood backing and does not provide risers. Wooden steps are anchored with chemical anchors, a fast-curing compound that is used to fill drilled holes in concrete.

To complete the installation, it is necessary to determine the installation site and mark all the elements. Then drill holes in the concrete and fix the steps with a chemical anchor.

Required tools

You will need tools to finish the concrete staircase with wood.

For preparatory work:

- putty knife;

- roulette;

- pencil;

- plumb line.

For installation work:

- a hacksaw with a fine tooth for wood;

- a hammer;

- electric jigsaw;

- puncher;

- electric drill;

- a circular saw;

- Sander;

- milling machine;

- screwdriver.

For work, you will also need a primer, concrete putty, dowels, liquid nails, glue, acrylic sealant and wood varnish.

Features of finishing a concrete staircase with a tree with your own hands

When choosing wood for facing steps, you need to pay attention to the performance characteristics of each species, and then to the cost.

Hardwoods (beech, oak, ash) are poorly processed and hard to polish. Soft species (pine, birch) are susceptible to mechanical stress. Any wood is afraid of moisture and flammable. To prevent rotting, pest damage and fire, the tree must be treated with special compounds.

When choosing wood, you should pay attention to the degree of drying. Poorly dried wood deforms during operation. Before starting the installation, the wood must be allowed to stand in order to acquire the optimal moisture level. This figure should be 12%.

Before carrying out facing work, the surface must be leveled, and the concrete must be thoroughly cleaned. This will increase the grip and strength of the seam.

Common mistakes

Many are trying to save money on certain materials, work, solutions. As a result, you can get not quite the desired result. The most common mistakes:

- Finishing without veneering. Some craftsmen use less time consuming and costly cladding technology. In this case, the quality and service life are significantly reduced.

- Savings on wood. Thin boards have low strength and short lifespan. It is better to choose boards with a thickness of at least 30 cm.

- Saving on glue. Inexpensive glue causes the linings to dislodge and detach from the warp.

- Saving on varnish. You cannot save on varnish, it will help to extend the life of the steps. Must be applied in 3 coats.

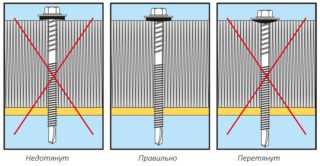

- Savings on fasteners. In addition to glue, experts recommend using dowels.

- Coating the stairs with paint. Such processing will hide the natural texture of the wood.

- Different step heights. Not allowed and may cause falls. The geometry of all steps must be the same; if necessary, it must be leveled.

Decorating a concrete staircase with wood will last a long time, if you follow the technology and do not save on materials.