The attic is located on the attic floor and is used for housing and other purposes. The room has a steeply sloped roof (35 - 60 °). Various materials are used for arranging the interior space, tk. Proper wall, ceiling and floor preparation allows the use of standard and non-traditional coatings. The attic is decorated in different styles, ranging from a rustic direction to a strict high-tech.

Preliminary work

The load-bearing structural elements of walls and roofs are made of metal, wood, reinforced concrete, therefore the external walls require insulation. Cold protection is installed on all horizontal and vertical surfaces or only in heated rooms. The material is chosen depending on which of the heaters have already been used during construction.

If the sloped roof has single-glazed conservatory-type dormers, such openings are equipped with modern double-glazed windows with a multi-chamber system. Finishing materials in drafts may become unusable.

A ventilation system is placed in the room, an inflow of fresh air and an outlet of exhaust air are organized. For supply, window openings or filter valves are used, and the output occurs through ventilation ducts that are passed through the roof.

Determine the heating method before finishing the attic. Provide for the supply of heat from a common boiler, install underfloor heating or use portable convectors from electricity. They make new wiring or replace old aluminum wires with copper ones.

Before finishing, they carry out a professional design project or consider interior ideas on their own. In any case, you will need elaborate sketches, taking into account the combination of materials.

The main qualities of materials for finishing the attic

The choice of material for lining the attic depends on the preferences of the owner and his material capabilities, as well as on the purpose of the premises in the attic. Living rooms, a kitchen, bathrooms and workshops are arranged in the attic space.

Interior materials must have the following properties:

- increased isolation from noise;

- external attractiveness;

- easy maintenance and cleaning, the possibility of repair;

- affordable price.

If the heating is arranged from a warm floor, the ceramic tile covering will effectively serve for a long time. In the bathrooms, the walls are laid out with tiles, and the ceiling is made with plastic or tension systems are installed. Door frames and door leaves are purchased from natural wood, but options from pressed solid wood or metal-plastic are suitable.

Standard materials used:

- sheets of ceiling and wall drywall;

- lining made of natural wood;

- imitation of a bar;

- polyvinyl chloride (PVC) panels and MDF;

- block house.

Coatings can be combined using color zoning and different finishes. For example, the walls are sewn up with wood, and the horizontal part of the ceiling is beaten with plasterboard, taking into account the beams in the attic.

Types of materials

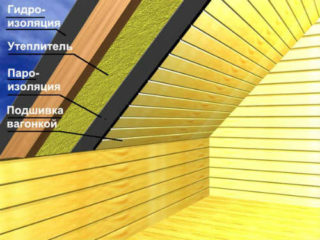

For thermal insulation and at the same time vapor barrier of walls, fiberglass and basalt slabs with a foil layer on the outside are suitable.They are easily installed with their own hands when decorating the attic floor of a wooden house, protect surfaces from moisture, condensation and the interior from cold. Plates are laid in the cells of the lathing from a wooden lath.

In living rooms, bedrooms, drywall is putty and painted with colored acrylic compounds. Sometimes the walls are covered with wallpaper, while they take calm tones, given that the space is well lit with light from large windows. If the openings are small, juicy and bright colors are used. Wallpaper is glued on a special backing for additional protection of the coating and increasing the service life.

A stretch ceiling system is placed on top, which will hide the beams and other structural elements, level the surface. Plasterboard is used for covering in several tiers at the request of the owner with spot or hidden backlighting. Decorative niches are provided in the walls. They use wall decoration with fabric, which is combined with other types of materials.

The tile is used in bathrooms and toilets because of its moisture resistance, strength and attractive appearance. Glass and plastic panels are placed on the walls of the kitchen in the work area. The room is finished with a cork covering, which creates coziness and additionally insulates the area. Natural material is produced in the form of separate three-layer panels, cork-based wallpaper and self-adhesive tiles.

Drywall

The material that makes it possible to sheathe the most difficult surfaces is placed on a frame made of galvanized profiles. It masks the unevenness of the walls, ceiling, and communications are hidden behind a layer of slabs. Plasterboard is produced as moisture resistant (green sheets), fire resistant (gray panels).

The material is suitable for finishing the attic floor, due to the characteristics:

- ecologicaly clean;

- does not require preliminary leveling of the area with a wet method;

- hides wiring, pipes;

- additionally insulates the room from cold and sounds.

The disadvantages of the material are that working with the frame device and the hinge of sheets requires professionalism, otherwise the surface will look sloppy, and irregularities will have to be leveled with a thick layer of putty.

For the floor, drywall is not used, because it does not withstand stress and breaks down.

Proper storage and transportation is required to avoid deformation.

Sheets with a thickness of 9 mm are placed on the ceiling, from a length of 2.5 meters. The wall panels are 12 mm thick and the length is increased to three meters. The frame is made of a CD profile, the strapping is set with the UD brand. For partitions, double CW posts are used, which are inserted into the belt from the UW profile. The profiles are fixed to the wall using the EC bracket, they are available in lengths of 90, 120, 150 mm.

For reinforcement, two layers of sheets are placed on the walls and ceiling. After installation, the joints are glued with a mounting mesh for seams and putty. The joints are pre-primed. In the future, a high-quality putty for painting is performed or finished in another way.

Lining

Natural wood material creates coziness and romantic rustic mood. Practical lining belongs to elastic types of attic sheathing and compensates for imperceptible vibrations of the attic floor walls under wind and temperature loads.

Varieties for the original wood:

- Fur tree, pine tree. They are installed in interior rooms without large temperature differences in the range from -5 ° C to + 30 ° C, with normal microclimate humidity. Conifers emit phytoncides, useful in counteracting microbes and disinfecting the air.

- Linden. Used for wall cladding in saunas and other wet rooms.

- Alder. It tolerates high humidity and temperature fluctuations. Used for unheated rooms in the attic floor.

The panels are joined with a tongue and groove. There are varieties in which spike gaps are visible at the junction, as well as where the stripes are connected closely together.The initial raw materials are selected for moisture content, the final products are checked for the accuracy of geometric parameters and the quality of surface grinding. Some species are equipped with ventilation grooves on the back to remove steam, which excludes the beginning of rotting.

Timber imitation

The material is a low-thickness board, processed from two sides. The ends are provided with tongues and grooves for fixing the elements to each other. Boards are made from solid natural logs.

Advantages of cladding:

- ecological cleanliness;

- ease of installation;

- long-term operation without loss of properties;

- variety of choices.

Fastened to walls made of brick, aerated concrete, wood, monolithic reinforced concrete.

It is recommended to first bait the imitation timber trim onto the walls and wait for the dimensions to shrink. After that, you can make the final installation.

Timber imitation is divided depending on the variety:

- Extra. Belongs to the category of high-quality goods with a clear geometry, no rotten knots. The thickness is uniform throughout the panel. It's expensive.

- Variety A (1). The imitation has knots up to 3.5 cm in size on the area, which sit firmly in the nest and do not fall out. Allows chips that are hidden during installation.

- Grade B (2). There are healthy knots in the material, falling out should not exceed the transverse dimension of 1 cm. Geometrical parameters are within the normal range, interlocking chips can be seen after being attached to the wall.

- Type C (3). A budget option with a lot of rotten knots that do not hold in the nest, there are chips and scratches on the surface.

Along the length of the panel, the imitation of the timber is produced from one and a half to three meters. To balance the grade of the product, groups of products are produced that combine the characteristics of the BC and AB categories.

MDF and PVC panels

MDF material is used when decorating entrance groups, offices, billiard rooms. For living rooms, a combination with painting, decorative plaster, wallpaper is used. The panels protect against sound and retain heat, no need to level the walls before installation. There are different options for cost, color, texture and width, so it is easy to choose the right type of covering for the attic. Produced with imitation of natural stone, wood, brick, fabric, braids.

Varieties of the surface of MDF panels:

- laminated - covered with polyvinyl film;

- veneered - revetted with wood veneer;

- painted - with increased resistance to chemical components when coated with protective compounds.

Plastic (PVC) panels are produced in all kinds of quality, designed for different categories of consumers. For installation, it requires a frame from a profile, as when finishing an attic with plasterboard. It can be glued onto flat areas without strips.

The material is strong enough, but does not withstand impacts. It does not bend on the ceiling. The walls at the bottom are trimmed with a more shock-resistant material, and plastic is placed in the middle.

The panels are not afraid of moisture and steam, therefore they are used in the kitchen, bathroom, toilet. Maintenance is easy, but cannot be cleaned with abrasive products.

Block house

The material is represented by wood bars, which create a covering with an imitation of rounded logs. It is a kind of euro lining and decorates the room in the style of a rustic interior.

Positive qualities of block house:

- resists moisture, mold does not develop on it;

- refers to environmentally friendly species;

- scratches can be easily removed from the surface.

Before installation, the panels are impregnated with an antiseptic, and a frame made of slats or a metal profile is arranged as a basis. Insulation and waterproofing are placed in the intervals of the base, then the panels are installed. After finishing, the surface is varnished in 2 - 3 layers.

Produce wood and vinyl material.

The natural variety is divided into classes:

- A - it is expensive, but the ideal quality does not allow holes and knots;

- B - the budget option is made from boards with defects;

- AB is an intermediate type at an average price.

Vinyl block house is a plastic strip of improved quality. They are used for exterior wall decoration of the attic. The appearance resembles processed logs of various colors, shades and textures.

Stages of sheathing the attic with your own hands

The attic inside is finished with his own hand using a marking tool, a drill, a jigsaw. Take pliers, a hammer, use a cord, level, plumb line.

Work order:

- After marking, they put a frame strapping on the ceiling or walls, and vertical frame racks are installed in it according to the level.

- The verticality is regulated by a plumb line or level, the racks are fixed to the wall with brackets, metal profiles are fixed in them with a self-tapping “flea” screw.

- Thermal insulation is placed between the longitudinal and transverse elements, fastened with dowels to the wall with large caps.

- Plasterboard sheets are placed vertically, the joints alternate on the ceiling in a checkerboard pattern, they are attached to the profile with self-tapping screws for metal.

The final finishing depends on the wishes of the owner. The surface is putty, while all layers are primed to increase adhesion. Subsequently, they are painted, trimmed with liquid or vinyl wallpaper, tiles.