The lining of a steam room is a laborious but important process. The decoration of the steam room in the bath includes covering and insulation of floors, walls and ceilings. They pay attention to practicality, while not disregarding the aesthetic side of the issue. The lining of the resting place is done according to a certain technology in order to avoid heat loss and maintain the comfort of the internal microclimate.

- General characteristics of bath rooms

- The choice of materials for interior decoration of the bath

- Materials that cannot be used for the steam room

- Choosing a tree for decoration

- Steam room thermal insulation

- The choice of insulation and vapor barrier

- Floor insulation

- Wall insulation

- Which one to choose and where to install the oven

- Ceiling, wall, floor decoration

- Installation of benches in the bath

- How to make shelves correctly

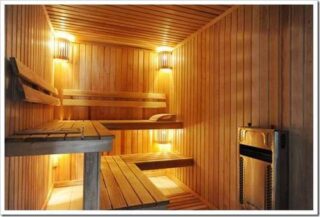

- Organization of lighting in the steam room

- Steam room ventilation

- Door assembly

General characteristics of bath rooms

The steam room is not always hot, there are periods when there are no visitors and the room is not heated. There is a temperature difference in the room, this is especially noticeable in winter. During water hygiene procedures, the walls, floor and ceiling are saturated with moisture; when it cools, especially in frost, drops of water begin to destroy their structure.

During the bath procedure, high humidity and high temperature act on vertical, horizontal surfaces. As a result, the materials work in extreme conditions, which must be taken into account when choosing the sheathing of the steam room in the bath. Constant humidity contributes to mold growth in unventilated corners, rotting of supporting structures and coatings.

The choice of materials for interior decoration of the bath

Not all finishes can be used on the ceiling, floor and walls of the steam room. When determining the category of cladding, the specific microclimate of operation is taken into account.

The following requirements are imposed on building materials for finishing a steam sauna:

- resistance to water, inability to absorb drops of condensation and steam;

- resistance to the action of heated air, low thermal conductivity, so as not to get burned when touched;

- durability of work in extreme conditions.

The characteristics of finishing materials, their level of environmental safety affect the internal comfort and microclimate. The cost of building materials, insulation and other insulators plays a role.

Materials that cannot be used for the steam room

The decoration of the steam room in the bath is carried out only with natural species, but not all types of wood are suitable for this. It is not recommended to use a coniferous tree, for example, pine, spruce. The composition contains many resinous components, which, when heated, are released into the environment, posing a danger to the respiratory system.

PVC is not used, since plastic begins to smell unpleasant in the heat. Ordinary tiles can crack at high temperatures. Also, linoleum is not put in the steam room, chipboard, OSB, other fiberboard and particle boards are not placed on the walls. In their production, formaldehyde resins are used, which are at rest at low temperatures.

Choosing a tree for decoration

Comfort is maintained due to the good protective performance of wood from the cold, while fuel is saved for heating. The tree is notable for sufficient strength, resists static and dynamic forces.

Use:

- larch;

- aspen;

- linden;

- alder;

- fir;

- cedar.

Aspen is easy to cut, withstands inside the mount, well resists heat and cold extremes, moisture. Larch has a high-quality density, strength, lasts a long time, tolerates repeated moisture.

Linden is a loose breed, easy to process, has beneficial properties for health.

Alder has a beautiful shade. Black alder is used for the bath.

Steam room thermal insulation

It is better to make insulation from the cold inside, since the internal heat should not be used to heat the wall itself. But the exterior decoration also plays a role in the arrangement of the thermos effect in order to increase the effectiveness of the bath procedure. If you do not carry out the insulation at all, condensation will appear on the walls inside, spoiling the material of the vertical fences.

They insulate not only the walls, but also the floor, as well as the ceiling. Mineral wool and cellulose mass have the ability to quickly become saturated with water, therefore they lose the properties of a heater. To solve the problem, a ventilated gap is made between the vapor barrier layer and the cotton wool using an additional counter lattice. So the insulation will not come into contact with the membrane and condensation will not form on the surface.

The choice of insulation and vapor barrier

Inside, only environmentally friendly species are used for the arrangement. It is not recommended to put polystyrene foam, polystyrene foam.

Allowed to sheathe surfaces in the steam room:

- some types of extruded polystyrene foam boards;

- foam glass;

- mineral, stone, basalt wool, slag wool, cellulose;

- foil polyurethane foam insulation.

Foil polyurethane foam works well, since the foil reflects infrared rays into the room. Thermal insulation is combined with the vapor barrier of the steam room. Roofing material, thick polyethylene are mounted, or special membranes are used that allow steam to pass only in one direction. Foil glass cloth or foil is used as protection against steam.

Floor insulation

To install thermal insulation for a solid floor of boards, a gap is provided between the finishing coating and the rough layer. Insulation is installed here along with a waterproofing film. If the floor is made at intervals for the flow of water, such a coating is not insulated. Instead, they insulate the foundation structures, pillars, piles from the cold.

In a concrete flat floor, insulation is laid between the rough and final screed, while a steam membrane and waterproofing are also used. Reinforcement of the coating is used, and before starting work, a drainage cushion is made of sand and crushed stone. Environmentally friendly materials are used for the floor, as well as for the walls.

Wall insulation

Before finishing the walls in the bath, an insulator is mounted from the cold inside the steam room using a hinged frame made of slats. The crate material is pre-treated with special antiseptics, anti-moisture agents, so that the frame does not collapse over time. Insulation is installed in the gaps between the posts and crossbars, then film waterproofing is laid.

The distance between the slats is calculated according to the width of the insulation, it is taken 20 mm less than the size of the slab or roll of the insulator. Planks with a section of 20 x 40 mm are fixed on the walls - small elements do not deform so much in extreme conditions.

Insulation is not fastened with plastic dowels; it is better to use metal anchors if walls are processed from foam concrete, aerated concrete, brick. In a log frame structure or a log house made of a profiled bar, the insulation is fixed with self-tapping screws with a galvanized coating.

Which one to choose and where to install the oven

More often in the Russian bath, a portable stove is used, which is mounted in the dressing room, and a channel is brought out to the steam room for the receipt of heat.Inside the steam room, they get clean air without burning and carbon monoxide, there is no debris from firewood and coal near the stove, space is saved for the location of additional shelves. In the hallway, the hearth takes oxygen from the room, so supply ventilation is arranged.

Choose the material for the manufacture of the heating hearth:

- brick;

- steel;

- cast iron.

The power of the heating unit plays a role. Too much heating does not always have a good effect on the comfort of the microclimate, and the degree of heating of the stones also matters. A low-power firebox will wear out faster, since it will work at the limit of its capabilities.

Ceiling, wall, floor decoration

The ceiling can be trimmed with boards, while the insulation is placed inside the steam room. Sometimes, when decorating a steam room in a bath with their own hands, insulation is placed from the side of the attic, then you can use polystyrene, expanded polystyrene.

A concrete bath floor must be finished to increase the operating time:

- iron - rub a thin layer of cement on a damp, just set surface;

- cover with ceramic tiles, porcelain stoneware.

According to safety instructions, a grooved finish is used so that the surface does not slip. Wooden laths are installed on the floor, which are taken out to dry, and changed in case of breakdown. For the walls, use natural lining or hardwood board.

Installation of benches in the bath

During the procedures, visitors sit comfortably or lie on benches. In the steam room, one-tier, two-tier three-tier shelves are made. Seats with one level are placed between opposite walls or placed in the shape of the letter L in the corner. The lower benches are made movable to dry outside.

Shelf dimensions:

- seat width - 60 cm;

- for lying - 90 cm;

- the minimum length for lying is 1m 50 cm;

- height between tiers 60 cm;

- the gap between the opposing benches is at least 80 cm.

For the bathhouse attendant, a special flooring with a height of 80 - 90 cm is provided for the convenience of work. The height of the first bed is adjusted to the size of the stove in order to get the maximum steam effect.

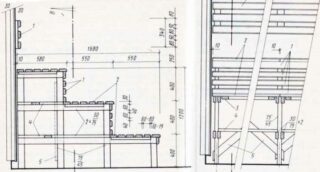

How to make shelves correctly

First, a drawing is prepared with the dimensions of all structural elements.

Step by step description of work:

- Racks are cut out of a bar with a section of 100 x 100 mm, they are fixed to the walls, cross-members and struts are provided between them for strength.

- For the boardwalk, longitudinal girders with a section of 80 x 60 mm are fixed with transverse supports in an amount of two or three tiers.

- Longitudinal boards of shelves with a thickness of 30 - 40 mm are laid at intervals of 1 cm so that steam can pass and water flow down.

Boards can be placed not along, but in width, then there will be material savings on transverse supports. The elements are connected with steel hardware, but they are driven deep inside so that visitors do not burn themselves. The design of multi-tiered shelves must be reliable and stable.

Organization of lighting in the steam room

Before sheathe the steam room, carry out the wiring, because in the bath, due to the difficult working conditions in the steam room, a hidden version of the wiring is recommended. They use cable varieties that can withstand temperatures up to 180 ° C.

Do not lay the wire in metal boxes, steel braided hoses. Open wiring on the walls is allowed if rubber hoses are used, and asbestos is laid under the cable so that it enters 10 cm from both sides of the wire.

In the steam room, the lamps are not placed on the ceiling, but only on the walls; they use waterproof housings.

Steam room ventilation

Effective ventilation is provided in the steam room, since air exchange reduces humidity at the time the bath is idle, so that the finishing materials and furniture are not destroyed by condensation.

Types of ventilation in the steam room of the bath:

- natural;

- forced;

- air recovery and purification system.

The first option provides for the movement of air flows through channels in the walls, or through suspended air ducts under the ceiling. Air enters through vents or ventilation openings. Forced exhaust and intake of air is provided by fans. A sophisticated automatic cleaning system is rarely used in a bath because of the high cost of equipment.

Door assembly

The steam room has an entrance door, sometimes there is a closing opening to the washing compartment. The sash in the tray sits firmly, without gaps, but opening should be easy, without effort.

Step-by-step guide to work:

- assembly of the door and sash;

- marking the hinges on the box and the canvas, installing the corresponding parts of the canopies;

- installation of a trap in the opening, spacer before applying foam, foaming;

- hanging the canvas on the awnings after the foam has hardened, trimming;

- installation of seals, false strips;

- installation of platbands.

Choose solid wood so that awnings and handles are kept in it. Opening the doors from the steam room is always done outside for safety reasons.