Ondulin is used to cover the roofs of various residential and industrial buildings. The demanded material is produced in a standard size in different colors. A new roof made of ondulin is easy to install, and sheets are also used to repair the roof. Euroslate flooring (common name) has an attractive appearance and long service life.

- Ondulin properties and service life

- Material production

- Calculation of ondulin for the roof

- Calculation of the pitch of the lathing and the volume of material

- Technical characteristics of ondulin

- Advantages and disadvantages

- Features of mounting a roof made of ondulin

- Installation of the lathing

- Installation of ondulin

Ondulin properties and service life

There are two types of ondulin - tiles and slate. In private housing construction, large corrugated sheets are used, which makes it easier to work with euro slate. Products can be categorized as composite materials because they are laminated products.

Components included in sheets:

- fibrous cellulose base;

- refined modified petroleum product;

- impregnation from mastic based on polymers;

- the top layer of mineral chips;

- coloring mineral pigments.

The composition is simple, but when choosing the type of ondulin, they study the instructions to find out what a particular variety is made of. Sometimes an uncertified product comes across on sale, which threatens to deteriorate the quality of the flooring. If the composition does not meet the norms and conditions of the standards, even if the technology is followed, the reliability of the coating will remain in doubt.

The weight per square meter varies at the level of three kilograms. Low weight allows you to lay sheets on the old flooring, excluding the standard installation technology. Manufacturers guarantee a service life of 15 years, but the material remains intact for up to 30 - 40 years, while the color may fade. They produce sheets of green, brown, red and black saturated colors, but a muted shade.

A modification has been developed in the form of transparent sheets that allow a certain amount of light to pass through. A lightweight translucent roof can be used to cover gazebos, pavilions, hotbeds, small objects of urban architecture.

Material production

At the preparatory stage, the quality of raw materials is controlled. Waste paper is sorted, garbage is separated, and treated waste is converted into pulp. Glass fibers, petroleum products, mineral fillers are added to the composition to increase the tensile strength. Dyes are added to the general paste before bituminous impregnation, so the color is preserved and does not fade for a long time under the influence of the sun.

The wet mass is dried on a heat conveyor of a certain width, where it is simultaneously pressed and given a wavy shape. The corrugated sheet is cut into equal lengths and impregnated with polymer bitumen mastic on both sides. A layer of mineral chips is glued on the surface to increase the operational properties.

Products are packed in shrink film. The layer shrinks under the influence of temperature, repeats the waviness. Thanks to this, ondulin is protected from moisture, dust, UV radiation during transportation. A label is attached to the package with information about the composition and size of the sheets.

Calculation of ondulin for the roof

You can calculate the number of sheets that will go to the roof of ondulin yourself, since the calculation is simple. You can use an online calculator and find out the required number of products for a certain area of coverage.

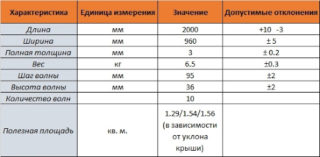

The common stripe size is:

- length 2 m;

- width 95 cm;

- there are 10 wavy protrusions on the sheet;

- wave width 9.5 cm.

The calculation is carried out taking into account the fact that the correct laying involves an overlap along the length, when each subsequent sheet is placed with an approach to the previous element by at least 14 cm.The bottom row is shifted down by 7 cm.On the sides, 2 waves go to the overlap (one with each side), while on the extreme products, one wave is released outward. With this method of the device, the useful area of the sheet is 1.6 m². This value is not always correct, since the size of the overlap changes depending on other parameters. The indicator is influenced by the slope of the roof.

The useful area indicator is (according to the manufacturer's recommendation):

- slope 5 - 10 ° - useful square is 1.29 m²;

- slope 10 - 15 ° - 1.54 m²;

- slope greater than 15 ° - 1.56 m².

For further calculation, you need to find the roof area. To do this, multiply the geometric parameters of the slope and add up the areas of all inclined surfaces. Suppose the square of the roof is 46 m², and the ondulin will be laid on the roof with a slope greater than 15 ° (this is how most decks do). Divide 46 by 1.56 to get 29.48 (30 sheets).

The recommended stock for cutting is 5 - 10% to keep within the required cut. 30 times a percentage and you get 32 sheets. Nails are counted based on the fact that there are about 20 pieces per strip. Multiply 30 m² by 20, add the stock percentage, and you get 630 nails.

Calculation of the pitch of the lathing and the volume of material

Competent installation of the flooring depends on how the step between the base bars for ondulin is correctly determined. The size of the step is recommended by the manufacturers of euro-slate and depends on the angle of inclination of the roof.

Indicators of the size of the gap:

- slope at an angle of 5 - 10 ° - the slats are placed in a solid, chipboard, OSB, moisture-resistant type of plywood, edged board are used;

- the slope is 10 - 15 ° - the optimal distance between the bars is a distance of 45 cm;

- tilt more than 15 ° - the step of the lathing is taken at the level of 60 cm.

The length of the slope is measured, for example, it is 6 m. The height of the plane is 3 m. For installation in height, 6 strips are obtained, two more are placed below and above for the cornice and ridge, for a total of 8 pieces. Multiply 6 m by 8 pieces, get the amount of 48 meters. If the roof has 2 slopes, then the number is multiplied by 2, you get 96 meters of a bar.

The battens of the lathing are connected only on the rafters, therefore, the consumption of material will increase, taking into account the cutting to the required size. For this, a factor of 1.1 is used. Multiply 96 meters by 1.1 and get 106 p / m slats. Suppliers often sell timber at a price per cubic meter. To translate the resulting lath volume into cubic capacity, multiply the section of the bar by the number of meters. For example, 0.05 · 0.05 · 106, the result is 0.256 m³.

To calculate a solid plywood base, the area of the slopes is taken and multiplied by the cut factor. For example, the area is 46 m2 · 1.1 = 50.6 m2. According to the rule, the resulting value is divided by the area of the plywood sheet and the number of elements that you want to buy is obtained.

At a step of 60 cm, the lathing sometimes bends (sags) under the weight of the material and snow. Ondulin has a rough surface, which prevents the rapid rolling of the snow mass. Manufacturers recommend taking a gap between the bars at the level of 45 cm.

Technical characteristics of ondulin

The standard sheet size assists in the correct material sizing for a variety of applications. The dimensions approved by the manufacturer are a guarantee of quality. Ondulin belongs to the demanded and popular roofing coatings, therefore, many fakes are sold on the construction market that do not correspond to the declared quality. If upon purchase there are significant deviations from the standard sizes, such products are not original.

The sheet thickness is 3 mm, but the difference in this parameter is not considered a defect, since the production technology allows small errors. The productive area of the sheet depends on the slope and overlaps, and the theoretical square is 1.9 m². The sheet weighs approximately 6 kg.

Other technical parameters:

- The corrugation is 36 mm high.

- Ondulin refers to substances that ignite when a certain temperature is reached; for euro slate, the limit is +240 - 300 ° C. This is a fairly low temperature, so the material is prohibited for use in child care and medical institutions.

- The surface of the flooring collapses at a force equal to 0.96 t / m², point impacts are more dangerous for euro slate.

- The material resists the action of chemicals in the environment. Does not react to alkalis, acids, oil products.

- The composition does not contain components harmful to humans and chemical active emissions do not enter the air. Safety is confirmed by a certificate of hygienic compliance.

- Does not pass or accumulate moisture in the thickness of the coating, protects the surface from dampness. Moisture resistance is maintained all the time of operation.

In appearance, the material resembles old-style asbestos-cement slate. The difference is that there is no asbestos in the composition, which is harmful to the respiratory system of people. Slate sheets can crack when fastened with nails, and with ondulin such troubles are excluded.

Advantages and disadvantages

Ondulin tolerates severe frosts in winter and heating from the sun's rays without destruction. In the off-season, the temperature difference between night and day reaches a large value, but covering the roof with ondulin solves the problem of surface destruction.

Material pluses:

- The light weight makes installation easier and reduces stress on the rafters and base of the house, so you can save on materials.

- The cost of euro slate is more democratic in comparison with metal profiled sheets or corrugated board.

- It is possible to change the color of the roof by painting with acrylic compounds.

The disadvantages include the fact that the strength of the material decreases when heated by the sun. In the summer, repairs are done along special wooden walkways, which are supported by a roofing ridge.

When heated strongly, a bitumen odor can be felt. On low-quality fakes, stripes of bitumen appear in hot weather, and the surface fades.

Features of mounting a roof made of ondulin

The correctness of the installation technology plays a role in maintaining the roof in its original condition for a long time.

Rules for stacking sheets:

- They do not step on the material in a loose state; if necessary, they slowly stand on the crest of the wave.

- Work is not performed in frost and heat above + 25 ° C.

- For fastening, use special nails that come with a coating.

During installation, you must not stretch the strips to get into the desired size, otherwise the overall appearance of the roof will be sloppy. The overlap in width and length is performed in one direction, starting from one corner of the working area.

Special nails ensure the tightness of the coating. After installing the hardware, close the lid on the head, which is not suitable for simple nails. This is an additional weatherproofing for the hole. There are nails with a smooth or grooved stem, it is preferable to use the second option for strong fastening in the rail.

It is impossible to change with ordinary self-tapping screws, since the hole remains open for moisture and dirt. The consequences will appear in 2-3 years, and repairs will need to be made.

Installation of the lathing

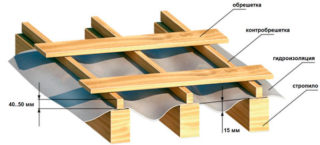

Conifers are used to make bars, boards or slats. The same thickness of the elements and the dryness of the material (humidity up to 20%) are important. The wood is treated with protective compounds against moisture, decay, microorganisms.Self-tapping screws for wood or screws with a length of at least 75 mm are used to fasten the bars together and fix them to the rafters.

Work order:

- insulate the attic, arrange a waterproofing membrane;

- mount wind boards, put a restrictive rail along the edge of the roof;

- fasten the cornice board, leveling it using a conductor - a pre-cut piece of a bar to size;

- the crate is mounted with a certain step, the solid base is placed with a gap of 2 - 3 mm;

- additional bars are placed in front of the ridge for mounting the head;

- slats are placed around the chimney and other protruding structures.

After installation, check the horizontal level of the common surface, correct shortcomings. It is not recommended to remove the installed sheets of ondulin to coordinate the plane, since this will lead to the appearance of an additional hole.

Installation of ondulin

For installation, a hand tool is used, the work is performed in clear weather without precipitation. The first step is to prepare the base for laying in the form of a batten or an old roof covering. Metal roofs are repaired and treated with anti-corrosion agents.

Stages of work:

- laying ondulin with cutting to size;

- final installation of additional parts.

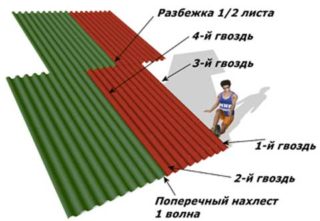

Lay the sheets so that the joint looks in the direction opposite to the prevailing wind direction in the region. Work begins from the corner of the slope, at least 20 nails are used in each strip. The material is cut with a hacksaw for wood. The sheets of the first row are laid in one piece, and the second is placed with the dressing of the seams in half, so the row starts with a half element, the alternation is performed in each tier.

The correctness of installation is regulated by a stretched cord, under which the wave height is adjusted. Self-adhesive tape is used to process the joints, nails are attached to the top of the corrugation. After the installation of the sheets is completed, the ridge is framed with a special element, the sides are placed around the chimney, snow holders and other additional elements.