Quite often, people are given little time to move from one apartment to another, so it is impossible to make even a slight cosmetic repair in advance, not to mention the possibility of a complete replacement of the finish. We have to resort to non-standard solutions. Laying the laminate on uneven floors is quick, there are no lengthy wet jobs and no time-consuming preparation of the substrate. It is not about laying the panels on a curved surface. Alternative alignment methods are applied.

Permissible difference in the height of the base

On sale are panels that differ in size, composition, thickness and methods of joining. In the instructions for the product, manufacturers prescribe the maximum permissible horizontal deviation when installing the flooring.

For products with different types of locks, the following height difference is allowed:

- Lock - 1%;

- Сlick - 2%;

- vinyl materials - 5%.

If the connection is made with glue, a doubling of the maximum level of unevenness of the base is allowed. This fixation is characterized by increased strength and reliability.

Floor leveling methods

If in new buildings the surfaces differ in almost perfect horizontal, then in old houses the slabs sag up to 10 cm relative to the level of the walls on which they are laid.

To straighten such bases, the following methods can be applied:

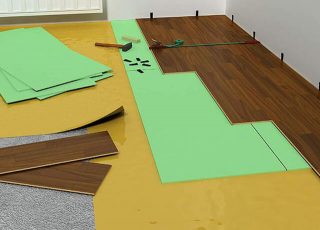

- Leveling underlay. Different types of material allow you to compensate for differences in the range of 1-4 mm, even within two adjacent masonry elements. In private construction, substrates made of wood fiber, polyethylene foam, polystyrene, expanded polystyrene, polyurethane, natural cork, and rubber have proven themselves well. However, this is not the most efficient option, since the substrate has a limited flexibility and resilience resource.

- Screed. New owners of secondary housing have to deal with a concrete base after dismantling the old coating that has become completely unusable. Even if the move is scheduled for the morning, you can have time to create a flat surface and lay the laminate on it. The first option is to pour a gypsum-based solution that dries for 2-3 hours. The second is leveling the slab with expanded clay and covering it with foam-plastic slabs.

- Wooden floors. Laying laminate on parquet or boards is possible only if they are well preserved, not affected by mold and insects. Bumps and protruding fragments can be removed with a sander or belt sander. If there is a strong slab deflection, it is better to use thick plywood laid on a leveling frame made of timber.

It is necessary to decide which method is better in each case, evaluating all the nuances and circumstances of the repair.

Advantages and disadvantages of methods

The choice of how to prepare a flat base for laminate flooring depends on a number of factors. The main ones are the time available, the degree of curvature and the state of the base.

You should focus on the pros and cons of each of the available methods:

- Substrate. It is set up very quickly and easily, but it has limitations on the maximum level of compensation for differences in height.

- Concrete screed. It is guaranteed to give a good, close to ideal result, but it takes time to mix the solution, harden it, grout the surface, treat it with an antiseptic and a primer.It is faster with bulk material, but to level it, you will have to install screeds, and the filler itself sags over time.

- Frame on wooden flooring. It is done quickly, ensures the constancy of the shape, but the coating and frame are expensive. In addition, it takes a lot of time to survey, repair and prepare the foundation.

There is simply no one-size-fits-all solution. It is necessary to objectively assess the situation and make the most appropriate choice for it.

Preparatory work

The installation of the laminate does not begin immediately after its purchase, but after careful preparation of the place of work.

- Carrying out measurements, determining the geometry of the base.

- Comparison of the obtained data with the permissible floor difference for laying laminate purchased for repair.

- Defective spots identification. Removal of fragile fragments, moldy areas, sealing cracks and holes. Treatment of supporting structures and surfaces with an antiseptic.

- Alignment in accordance with the selected technology.

Further actions are carried out after checking the quality of the work performed and the complete drying of all used solutions and liquids.

Required tools and materials

For each method of eliminating the curvature of the floor, its own set of tools and materials is being prepared.

For substrate:

- scissors;

- Scotch;

- glue.

For concrete:

- shovel;

- puncher;

- rule;

- profile for beacons;

- needle roller;

- putty knife;

- self-leveling mixture.

For wood flooring:

- hacksaw;

- ticks;

- screwdriver;

- a hammer.

In all cases, you will need a level, tape measure, paint brush, antiseptic, mallet, mounting foot and damper tape.

Laying instructions for laminate flooring

Laying laminate flooring takes care, patience and peace of mind.

Instructions:

- The first panel is installed in the left far corner. The first row is assembled by joining into the lock, the last fragment is cut to length.

- The second row begins with an offset by half the board, the same is done further to the penultimate line.

- The outer row is trimmed to the width and inserted into the flooring using the mounting foot.

The final step is to install the skirting boards by screwing them to the walls.

If you put the laminate on an uneven floor without first reaching the horizontal, then the consequences may appear immediately or later. Initially, the coating will be uneven, since it will not be possible to achieve the required locking technology. Then, due to additional loads, they will loosen, which will lead to the appearance of cracks. Water inevitably gets into them, which will cause the flooring to swell and lose its presentation. Ultimately, the curvature will completely destroy the coating.