When planning the construction of a residential building, summer house, cottage, bathhouse and other structures on a land plot, attention should be paid to all elements of the building. One of them is a roof that protects it from precipitation, heat and cold, debris, animals and insects entering the attic. The strength, functionality and stability of the roof is determined by the rafter system. There are many types of frames, which are divided by the number of slopes, height, width, depth and material of manufacture. The roof rafter system is selected after analyzing each option, assessing its applicability to the structure of a certain style, number of storeys and external design.

The device of the rafter system

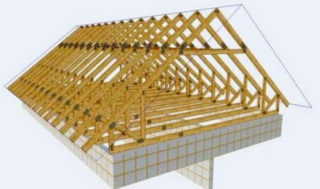

The rafter structure is represented by numerous cross-beams located in a horizontal, vertical and oblique direction. Roof structures are designed to accommodate covering materials and must withstand environmental influences for a long time.

In accordance with building codes, roof rafters must meet the following requirements:

- Rigidity. The elements of the frame system are affected by compression, bending and tension. The trusses are assembled in a triangle shape with strong, fixed connections.

- Ease. Rafters are beams made of wood, each of which is quite heavy. To reduce the pressure on the walls and foundation, the frame is made of conifers, which are distinguished by their strength, rigidity and low specific gravity.

- Durability. Houses are built for decades, and replacing a roof during operation is difficult and uncomfortable. The rafters are treated with hydrophobic agents, fire retardant and antiseptic, each docking point is reinforced with metal parts.

For the manufacture of the frame, you need to use wood of 1-2 grades or materials of similar quality. The presence of cracks, rot on the timber, deep rust and traces of poor-quality welding on the metal is not allowed. The dimensions of the rafters are determined by the material used and its size. For hardwoods it is up to 450 cm, and for conifers - 650 cm.

The main elements of the rafters

- Mauerlat. A support bar that takes the weight of the volumetric structure and distributes it evenly on the bearing surfaces.

- Rafter leg. Designed to form the shape of the roof and fix the outer cover.

- Run. Connects the legs of the rafters at the top and bottom, closing them in a triangle.

- Tightening. Prevents the truss from stretching, is installed in the middle of the truss.

- Rack. Serves as a support for the retaining rafter beam.

- The brace. Supports the rafter by transferring the load to the support base.

- Lathing. A structure with a lattice or monolithic surface. Designed for fastening cover material.

- Filly. A bar that is nailed to the rafter to form an overhang. A small cutout is made on the boards for fixing on the timber.

The installation of the rafters is carried out so that the parts are connected according to the thorn-groove principle. Additional fastening of joints is carried out with nails, staples, plates and corners.

Types of rafters and requirements

There are different types of materials from which roof frames are made.

- Metallic. Monolithic T-beams are used, less often - stamped profiles. Iron is highly durable, breakdowns during operation are excluded. The joints can be fastened with bolts, rivets or welding. The disadvantages of metal structures are their high cost, severity and susceptibility to corrosion.

- Wooden. The most common material for arranging the frame. They are used for the manufacture of all types of roofs - single-pitched, gable and hip. Provided that the wood is properly processed, the frame can stand for 50 years or more without problems.

- Reinforced concrete. The poles are characterized by their almost absolute strength and reliability, corrosion resistance, and no handling or maintenance required. The large weight of concrete products and the complexity of their fastening forces private developers to abandon this material. It is used mainly in the construction of large industrial facilities.

- Mixed. Structures consist of beams made of two or more types of materials. Support nodes are made of metal or reinforced concrete, and auxiliary parts are made of wood. This allows you to extend the resource of the building up to 100 years or more.

Having decided on the material for construction, you need to move on to choosing the type of rafter system.

Types of rafter systems for different types of roofs

When designing an internal structure, the following types of frameworks can be used:

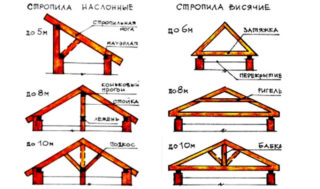

- Hanging. The beams rest on the Mauerlat, exerting significant tensile loads on it. To eliminate this factor, one or two puffs are installed between the rafters. This solution allows for more efficient use of the attic space.

- Forced. They are used for arranging buildings with a load-bearing middle wall. The rafter legs rest on the beam and the Mauerlat. As a result, only vertical pressure is exerted on the walls. This allows you to reduce the consumption of lumber and reduce the load on the building.

- Shed. The simplest project that can be done even alone. The angle of inclination of the slope varies between 6-35 degrees, depending on the type of roofing and the strength of the prevailing winds. Simplicity also has its downside - it is impossible to make a full-fledged attic.

- Gable. The most common option for private construction. The design optimally combines simplicity, practicality and lightness. It consists of two slopes connected by a ridge at the top. With a sufficiently steep slope, it is possible to equip a warehouse or living space in the attic space.

- Hip. They are various variations of four-slope designs. Two lateral sloping surfaces are made in the form of a trapezoid, in the end surfaces - in the form of a simple or broken triangle. Two-level structures are difficult to manufacture, but you can make spacious attics in them, put windows, equip open balconies and platforms.

- Broken lines. This type of roof is not only original, but also practical. By using insulation of sufficient thickness, heat loss through the ceiling and roof can be completely eliminated. Installing hanging rafters will optimize the interior space.

When choosing the type of rafter system, you need to take into account your own financial capabilities and construction skills.

Recommendations for choosing a roof system

The choice of the type of roof must be taken responsibly, taking into account the many factors accompanying the construction and operation of the building.

- Climatic conditions. These include wind and snow load, precipitation level. If there is a lot of snow in winter, you need to cover the house with material with a smooth surface. Strong winds are successfully resisted by a roof with little windage.If a decision is made to install windows, their design should be well thought out.

- The style of adjacent buildings. Every element of the house, including the roof, must be organically combined with them. But you cannot follow a complete coincidence. If the garage or sauna is covered with slate, it is not necessary to use this covering for the house.

- Landscaping of the yard. If there are only paths and mowed lawns on it, there are no special recommendations. When trees and shrubs grow on the site, flower beds and flower beds are broken, it makes sense to establish a hip or multi-tongued form.

Several sketches are recommended. This will help you make a decision. Drawing and calculations can be made for any project.

Features of installing a rafter system with your own hands

Do-it-yourself installation of the rafter system should be carried out after a careful check of the schemes and drawing up a work plan.

They are carried out in the following sequence:

- Install Mauerlat.

- Place and secure the supports.

- Place the rafter legs in the slots.

- Expose the elements that give the frame strength and stability.

- Make a crate.

- Attach the membrane film.

- Install the roof covering.

- Insert insulation between the rafters.

- Sheathe the beams with membrane foil.

- Carry out the interior finishing of the pitched surfaces.

At the final stage, the installation of the drainage system is carried out, the parameters of which must correspond to the roof area.

It seems to become sensible, it is stupid that everything is without specific pictures (photos, diagrams, sketches, etc.). If you write, support the photo with materials. Your site, I understand that it is not intended for professionals, but for amateurs and amateurs, so make the articles more understandable. This will only increase your rating, otherwise not everyone knows what LIDOBURITS are ...