The gazebo is an ideal place for a country holiday. Most often, wood is used for construction. It is not difficult to make a gazebo from a bar with your own hands, but you need to choose the right building material and observe the construction technology.

Types of timber for a gazebo

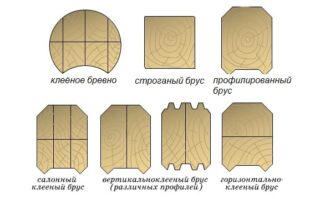

The advantage of wood construction is that it allows you to create a comfortable environment. For construction, the following types of timber are used:

- planed;

- rounded;

- glued;

- profiled.

Each of these materials has its own technical characteristics, advantages and disadvantages.

Profiled

Profiled timber is a processed material with grooves and cuts that facilitate installation. At the same time, the reliability of fixation increases. It has the following advantages:

- ease of installation;

- high structural strength;

- lack of gaps between the bars;

- small load on the base;

- wear resistance;

- minimum level of shrinkage;

- even distribution of mass.

Profiled timber is suitable for a beginner craftsman. Before installation, the wood will have to be treated with protective compounds that increase the resistance of the material to decay and ignition.

Glued

A beam is a certain number of boards glued together. At the same time, the building material acquires a high level of strength, and its decorative effect does not deteriorate. It has the following advantages:

- the ability to bend the product: even with shrinkage, the structure does not lose strength;

- attractive appearance;

- resistance to damage by insects and rodents.

You can make a gazebo from laminated veneer lumber yourself in 1-2 days.

Rounded

Before use, a rounded bar can be processed: the bark is removed from it. Has the following advantages:

- ecological cleanliness;

- ease of installation and processing;

- ensuring optimal air exchange;

- low thermal conductivity.

The disadvantage of a rounded beam is a large weight, therefore, before building a gazebo, it is necessary to build a foundation. This material cannot be called very convenient in laying, since large gaps may appear between individual elements due to drying out of the wood.

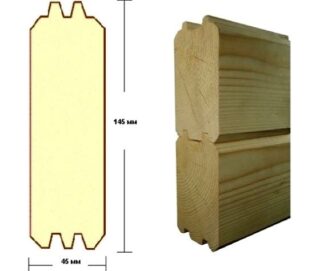

Mini bar

Mini timber is a planed board, the width of which is 14.5 cm, and the thickness is 4.5 cm. Each element is equipped with a spike and a groove, which makes it easier to assemble the frame. Additional adjustment of the bars on the construction site is not required. The material has the following advantages:

- easy installation;

- ecological cleanliness;

- ensuring good air exchange;

- low level of thermal conductivity.

Like any other wood material, the mini-timber is not resistant to inflammation, therefore it requires additional protection.

Section selection

Before you build a gazebo from a bar, you need to decide on the size of the elements.

The most used material in the construction of lightweight structures is a beam, the cross-section of which is 100 * 100 mm. It can be used to build a gazebo that can withstand a massive roof. The length of the elements is about 6 m.Pergolas made of 100 * 100 timber are reliable, durable, but do not differ in high aesthetics.

The size of 150 by 150 allows you to build a solid structure that can withstand a serious load. This material weighs more and costs more. The bearing capacity of this bar practically does not differ from the 100 * 100 mm option, but the aesthetics are much better.

A bar of section 150 * 50 mm is used for the construction of the lathing, rafter system. From this material, the base for the floor covering, the top strapping are made.

Advantages and disadvantages of a bar gazebo

The advantages of the presented building material:

- environmental safety (the timber does not contain toxic substances, so it does not harm health even when exposed to high temperatures);

- the ability to use in any landscape design;

- ease of installation even for a novice master;

- the possibility of recreation in the summer and winter;

- providing comfort;

- durability, resistance to mold, mildew (with pre-treatment with protective agents);

- a small level of shrinkage;

- when properly dried, the material is resistant to temperature extremes;

- small weight;

- the possibility of building structures of different sizes and modifications.

The wood construction has some disadvantages:

- relatively high cost of high-quality dried material;

- the need for periodic maintenance: varnishing, protective compounds;

- the risk of changing the shade of the tree under the influence of moisture, precipitation, temperature changes;

- low resistance to ignition.

The timber is damaged by rodents and insects. However, the tree is easy to repair. If you follow the step-by-step construction instructions, the gazebo will last for many years.

DIY construction

Work on the construction of the building provides for the preliminary preparation of the project, calculation of the amount of material. To facilitate construction, you can draw a diagram of the gazebo, make a drawing indicating all the dimensions and parameters of the structure. To create a project, you need to know the type of structure, its location. The drawing of the foundation is made separately.

Foundation foundation

When choosing the type of foundation, take into account the type of soil, the depth of groundwater. The installation site is chosen no closer than 1 m to the fence, other buildings. In the corners of the future gazebo, pegs are placed for marking and the cord is pulled. A trench is prepared under the base. Formwork is placed in it, concrete is poured. In this case, it is important to monitor the horizontal level of the foundation.

Laying the bottom strapping

For work, a bar with a section of 150 * 150 mm is used. Elements are treated with bitumen from the inside and from below. Notches are made along the edges of the tree so that the timber is fixed tightly. For fastening the elements, screws or self-tapping screws are used.

Floor lags

A bar with a section of 150 * 50 mm is suitable for laying. The distance between the elements is 80 cm. The distance from the edge of the foundation is 30 cm. Nails or self-tapping screws are used for fastening. They are fixed at an angle. The timber is pretreated with antiseptics.

Installation of vertical posts

If the option is closed, the timber is installed one on top of the other in accordance with the marking. When erecting an open gazebo, first, vertical pillars are mounted, and then they are fastened together.

Top strapping

The base for the roof is made separately. Connect the elements together by means of grooves. In this case, the angle of inclination of the beams is taken into account. For fixation, wood grouse screws are used. In addition, the type of roof is pre-selected: gable or single-pitched. Each corner of the structure is reinforced with metal corners.

Roof construction

The slope of the slope is at least 30 degrees. All spans are collected on the ground. For fastening the structure, steel plates and corners are used. A crate is fixed on top of it. For this, slats are used with a thickness of 2.5 cm.

Fastening roofing material

For the installation of a soft roof, a rigid base is required instead of a crate: moisture-resistant plywood. Lay it taking into account the deformation gap between the sheets. Depending on the type of material, bitumen mastic or self-tapping screws are used for fixing.

Flooring

As a floor covering, a board is used, the thickness of which is 4 cm. They are fastened with nails in 5 places.

Tips & Tricks

In order for the gazebo to be functional and comfortable, the following recommendations must be followed:

- during work, you need to use the building level all the time;

- if the structure needs to be used all year round, it needs to be insulated and glazed;

- if it is necessary to install a fireplace or barbecue, an additional foundation is required;

- the type of roof and the material of the roof are chosen depending on the dimensions of the structure;

- building material is purchased with a margin.

A good option for decorating a wooden gazebo is a slatted lattice of a darker color. You can also attach wooden planks horizontally or at an angle. Decorative panels are also used for work.