A quick way to build a gazebo is to sheathe a metal or wooden frame with polycarbonate sheets. The room can be made open or closed. A do-it-yourself polycarbonate gazebo is often constructed from shaped pipes.

Description and features of the material

Thermoplastic polymer material is widely used in construction due to its strength. Since it transmits a lot of light, but at the same time does not have fragility, it is often used for glazing and other purposes where transparent structures are required. It is produced in sheet form, including in color. The use of polycarbonate in several shades makes it possible to obtain beautiful ornamental designs.

Due to the combination of transparency and strength, the material transmits the sun's rays well, but protects people in the glazed room from precipitation and wind. This makes it a good choice for outdoor seating at any time of the year. Even if the structure is completely closed, enough sun will penetrate inside.

Polycarbonate is easy to handle, cut and drill. Flexibility allows you to create a roof structure of any shape, including curved.

Other pluses of the material include:

- light weight;

- ease of installation;

- low price;

- shock resistance;

- compatibility with most building materials.

Quality can be assessed by trying to push through the sheet with your fingers on both sides. If it breaks or bends a lot, it is better to look for another option.

Before starting work, it is necessary to prepare a drawing. When thinking over a project, the wind rose, the terrain, the dimensions of the structure are taken into account. You should also plan how the table and benches will be positioned.

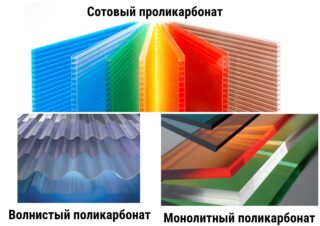

Which polycarbonate is suitable for gazebos

Wavy

These are corrugated sheets, due to their lightness, they are often used for installing roofs - both single-slope and more complex structures. The roof of the gazebo can also be made of them. It is a thin product: the thickness of the sheets can vary from 0.65 to 2.5 mm. Therefore, it is less reliable and durable than other options.

Monolithic

It is a shock-resistant material that is not easy to break even with a hammer and is therefore often used to replace glass. It bends well without heating, so it is also suitable for decorating a gazebo, including an arched roof. However, at temperatures above 40 degrees, material deformations are possible. To compensate for this effect, the distance between it and the frame is increased. The material not only replaces glass well, but is noticeably inferior to it in price. For a gazebo, such polycarbonate should be taken at least 4 mm thick.

Cellular

In cross-section, the material resembles a honeycomb of bees. More often there are options from 2-3 layers (they last up to 30 years). But you can also find five-layer products that can be used for half a century or longer. It tolerates heat well, but becomes brittle when frozen and can crack under light load. To level this feature, it is covered with a film.

Choosing a place and material for a gazebo

In small areas, the gazebo is often built next to the dwelling. If the homeowner lives near a body of water, a structure can be built close to the shore, allowing the family to relax by the lake or pond.

The posts for the frame can be wooden or metal. The first ones are easy to install due to their lightness, but they need antiseptic impregnation. The latter are strong and moisture resistant, but have a greater weight, which is why a reliable foundation becomes an important condition. It can be made columnar or shallow tape.

The foundation is also prepared for a wooden building, if it has sufficient weight. Pouring cement, it is left to harden for several days and only then proceed to further work.

Construction features

An edged board is suitable for flooring, and its frame is made of a bar with a section of 5x15 cm. The logs are mounted strictly horizontally in increments of 40 cm. A boardwalk is organized on top using self-tapping screws.

The design of the walls depends on whether they are completely transparent. Sometimes only a segment is made of polycarbonate, and in the rest of the frame, boards are horizontally stuffed onto the frame racks. The upper harness is made of square-section bars with a side of 10 cm. They are mounted in the L-shaped cuts made at the ends of the supports and fastened with nails driven in at an angle. Then load-bearing rafters and lathing are made and sheets are laid.

Indoors, you can put a table, benches or chairs. Wooden parts are varnished. You can make lighting in the gazebo.

A do-it-yourself gazebo made of metal and polycarbonate is made of steel pipes with a diameter of 5 cm.For rafters and strapping, you need a 4x4 cm corner.For fasteners, you need self-tapping screws designed for steel and brackets.

Of the tools come in handy:

- saw for cutting sheets;

- drill for soil;

- hacksaw for metal;

- pliers;

- welding machine;

- electric jigsaw.

To install the fasteners, you will need a screwdriver and a hammer. The work process is controlled by the level.

After marking, holes are drilled for the supports (dimensions: depth - 0.7-1 m, diameter - up to 10 cm), sand-gravel mixture is poured and pipes are mounted. They are concreted, and after a few days corners are welded to them. The floor is made of wood or concrete.

The horizontal supports are welded to the posts, and then the upper harness is created. The roof frame can be built on the ground. After that, it is welded to the posts.

The sheets are fastened with self-tapping screws with thermal washers installed in pre-prepared holes. For docking, you can use a plastic profile.

A gazebo with your own hands can be made from an aluminum profile and polycarbonate. The lightness of the material will make the process faster.

The foundation can be designed as a shallow tape. Metal fasteners for the profile are laid in it. Welding is well suited for joining the frame elements. Better to use a square profile. The sheets are fastened with self-tapping screws to the frame or crate. The type of parts used depends on the base material.