Change houses can be made of metal, wood, build in a frame way, then sheathe the sandwich with panels, shields, moisture-resistant OSB boards, boards. Ready-made modules are purchased on the market, but you can successfully build a change house with your own hands. Shop models are made using cheap materials, there is a saving in quality. A homemade version will not be much cheaper, but the owner will make the structure cozy, reliable, durable.

- Building options

- Material for the manufacture of a summer cottage

- Wood

- Shield

- From OSB boards

- From a metal profile

- From sandwich panels

- Choosing a place to build

- Building materials for a wooden change house

- Step-by-step instructions for the construction of a summer cottage

- Foundation device

- Frame installation

- Filling window and door openings

- Roof manufacturing

- Floor installation

- Finishing and insulation

- Internal arrangement

- Insulation of the floor and roof

- Heating options

- Useful tips when building a change house

Building options

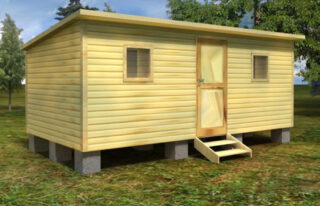

Almost all buildings are based on frame construction technology. For the frame, wooden bars are used; you can assemble it on the basis of a metal frame.

Schemes are common:

- Change house trailer. In the building, the entrance is located on the side, and inside it does not provide for any division of space. Sometimes a partition is installed at a distance of 1.5 - 1.8 m from the front door to separate the vestibule.

- Undershirt. The layout assumes an entrance in the center of a long wall; there are two partitions separating the central part from the side rooms.

The second version is the most common, since there are two isolated rooms, and in the middle they store tools and prepare food.

Material for the manufacture of a summer cottage

If the building is used as a place of residence, requirements are imposed on building materials in terms of environmental safety, especially for the interior decoration of walls, ceilings, floors. Frame construction involves the use of insulation, which is placed between two layers of cladding.

Wood

The structure is a frame of a change house made of wood, finished with clapboard on the outside, a block house. Inside, the walls are sheathed with chipboard, OSB, thick plywood.

Features of buildings:

- the roof is made on wooden beams, rafters, trusses;

- the floor is performed on beams from a bar.

Wooden cabins are lightweight, so a deep foundation is not required for their installation. Such structures are cheaper than metal ones, but they also last less (about 15 years). Transportable cabins are subject to different loads more stationary options. Insulate wooden walls with a layer of mineral wool.

Shield

Internal and external walls are fixed to the posts with solid panels. Panel structures are distinguished by minimal material costs and quick assembly.

As piece fences are:

- frames sheathed with chipboard, cement-bonded particleboards (DSP);

- board shields;

- blocks from the lining.

Insulation can be done simultaneously with the construction of walls. It is sufficient to install 6 - 8 prefabricated foundation blocks as a base for a light structure. An alternative is a shallow reinforced concrete tape.

From OSB boards

Large elements as wall cladding offer the advantage of rigidity. Such designs are intended for portable and transportable modules.

OSB boards have the following characteristics:

- made in the form of a multilayer sheet of shavings, which is bonded with resin with the addition of artificial wax;

- almost does not absorb moisture, does not swell from water.

The building material holds hardware well, does not crack, and is combined with various finishing layers. The disadvantages include low vapor permeability.

From a metal profile

With the help of a profile pipe, the frame can be given a different shape, arrange any layout of the room. To increase safety, openings are equipped with steel gratings, iron entrance doors are made.

Features of frame cabins made of metal profiles:

- walls are made with metal profiled sheets, sandwich panels with an inner layer of insulation;

- the roof is covered with galvanized steel sheets.

Inside the metal shed, an additional ceiling is hemmed to insulate the surface and protect it from noise.

From sandwich panels

The cladding material is lightweight, does not require reinforcement of frame racks and other load-bearing elements. The house is easy to build, the work does not take much time.

Properties of panels by type of sandwich:

- ecological cleanliness;

- stable fire resistance characteristics;

- moisture resistance;

- good thermal insulation, noise protection.

The panels of the decorative group are distinguished by their beautiful appearance, the facing plates are installed all year round, regardless of the air temperature.

The disadvantage of sandwich panels is the impossibility of repairing if the plane is damaged, a complete replacement of the element is required.

Choosing a place to build

They draw up a plan of the land allotment, mark the existing objects.

The change house is erected away from a residential building or a place designated for it in order to ensure the movement of cars, a crane, and other mechanisms.

If the building is made for storing inventory, tools for a ready-made summer cottage, a change house is placed in the back of the yard.

The module for human habitation is placed in such a way as to bring the sewage system, water supply, and make heating.

Building materials for a wooden change house

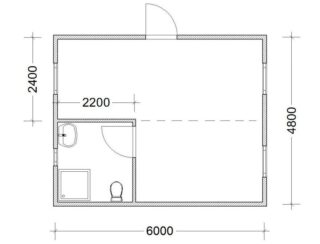

The list was drawn up for the project of a change house measuring 3 x 6 m, the building is insulated.

Building materials used:

- boards with a section of 50 x 120 mm - 30 pieces;

- bars 150 x 100 mm - 6 pcs., with a section of 50 x 60 mm - 22 pcs.;

- roof planks 25 x 120 mm - 16 pcs.;

- foam concrete blocks measuring 40 x 20 x 20 - 22 pcs.

For the floor, grooved boards with a thickness of 30 - 35 mm are used, the outer walls are revetted with clapboard. Waterproofing layers are made with roofing material, foam insulation (outside). For fastening, self-tapping screws, nails, steel corners are used for rigidity.

Step-by-step instructions for the construction of a summer cottage

The layout of the building is important to make the change house comfortable. Subsequently, such modules are converted into a guest house or a bathhouse.

Before starting construction, you need:

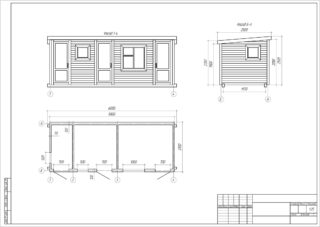

- draw up a drawing of a change house with exact dimensions, indicate in it the axes, dimensions of the structure, heights of all structural elements;

- develop an estimate with a list and quantity of materials, works, mechanisms used, transport.

The estimated calculation includes the cost of electricity, water.

The project will help to correctly calculate the costs and identify the amount of work that you can do yourself.

Foundation device

Factory-made foundation blocks are placed under the wooden shed, or monolithic posts are concreted directly in place. For a change house that is small in width (no more than 2.5 m), the supports are installed in the corners. On the long sides, the posts are placed in increments of 1.5 - 2.0 m. If the change house is wider, then an intermediate row of blocks is mounted in width between the two corners.

A small pit is dug under each block, at the bottom of which they make a pillow of sand and gravel. After tamping, put the elements, align their plane to the level.

Frame installation

A strapping bar is laid on the blocks, connected in a half-tree way. For reliability, they are fixed with iron pins.

Step-by-step order:

- floor logs are laid with a step of 0.5 m from boards with a thickness of 50 mm, installed on the edge;

- racks are placed from them through one, they are joined to the rafter legs on the ground, then they are mounted in place in the complex;

- racks to the harness are fastened with nails 150-200 mm long, iron corners or steel plates are used at the joints.

Racks are reinforced with crossbars, struts made of bars. Bearing elements for installing insulation are obtained.

Filling window and door openings

Wooden frames are environmentally friendly, withstand frost and temperature extremes well. After processing and impregnation, the surface of the windows is not afraid of moisture, the resistance of the frame to fire increases. Natural material allows circulation of air currents, preventing the development of mold and mildew.

PVC frames are inexpensive, easy to install in openings. The product retains its heat at low temperature levels thanks to the technology of multi-chamber double-glazed windows.

Roof manufacturing

For a pitched roof, the rafters are supported on beams that are located at different heights to create the desired slope. The rafter legs are fixed with pins, brackets. The roof structure must be fixed to the frame so that the wind does not move it.

Along the inclined elements, a lathing of 30 x 40 mm slats is arranged for the roofing. The step of the slats is chosen depending on the material, its strength characteristics, and weight. Take into account the snow and wind load, the slope of the slope.

Floor installation

A wooden insulated floor is ideal. From above it is varnished 3 times to reduce wear.

Floor covering techniques:

- the boards of the subfloor are hemmed along the logs, protective films are placed on it to prevent wind and moisture from blowing out, the edges are brought onto the walls (20 cm);

- expanded clay, sawdust are poured between the logs, slab or roll insulation is placed.

After the installation of the vapor barrier, grooved boards of the finished floor are placed, sometimes chipboard panels are used. Then the surface is painted or finished with tiles, linoleum.

Finishing and insulation

The lining is collected on the wooden frame elements, which serve as a support for the lamellas. Pay attention to wall decoration around window and doorways. After finishing the cladding, decorative platbands are installed on windows and doors.

For finishing, you can use a profiled sheet, cement mortar panels with shavings. The latter material is durable, but creates an additional load on the foundation, therefore, the base of the change house is reinforced.

Internal arrangement

Before sheathing the inner plane of the walls, a heater is placed, then the surface is revetted with a finishing material. Chipboard panels are used, then you can put any material that will be appropriate in the operating conditions.

Plastic trim is common; washable wallpaper is glued in the residential area. A simple option is to paint the walls with oil, acrylic, latex, pentaphthalic compounds. Sometimes a stain with several layers of varnish is used.

Insulation of the floor and roof

For the floor, mineral wool is used, which can be represented by glass wool, slag, stone wool. The material requires that it be insulated from contact with moisture and condensation. For this, a ventilated gap is made so that there is a possibility of drying.

On the roof, polystyrene, expanded polystyrene, polyurethane foam are used. They are laid in the elements of the roof lathing or installed when installing a false ceiling. At the same time, a vapor barrier and waterproofing are mounted.

Heating options

In wooden buildings, equipment is used that is safe in terms of fire, which does not have an open flame.

Common methods for heating cabins:

- wood-burning stove potbelly stove;

- multi-pass furnace structures;

- electrical units (oil coolers, blowers, electric boilers);

- LPG gas convectors;

- liquid fuel equipment.

The choice of heating method depends on the preferences of the owner, his material capabilities.

Useful tips when building a change house

During construction, you need to focus on the standard technology of joining corners, beams, rafters, you should not take into account untested methods.

When drawing up a project, you need to take into account the location of plumbing devices in the change house, determine the place of the washstand, electrical panel, lamps, air conditioner in order to put additional supports in the form of slats.

If you need to quickly build a change house, it is better to order a ready-made frame, which is then sheathed with your own selected materials.