Chickens fly almost as efficiently in winter as in summer if kept at normal temperatures (10-20 ° C). The winter chicken coop is well lit, ventilated and insulated. Various materials serve as material for walls, floors, roofs. The owner chooses the option of the poultry house in such a way as to equip acceptable conditions and not spend extra money on construction.

- Differences between winter and summer chicken coop

- Building requirements

- Types of warm chicken coops

- Polycarbonate

- From blocks

- From cinder blocks

- Preparation for construction

- Materials for building a chicken coop

- Tool for work

- Step by step construction process

- Foundation device

- Erection of walls and roofs

- Floor installation

- Warming

- Ventilation arrangement

- Organization of lighting

- Internal arrangement of the poultry house

- Heating the poultry house

- Walking yard

Differences between winter and summer chicken coop

The design of the summer house is a lightweight structure that provides a roof for the birds in the spring and summer. At this time, pets grow, lay eggs, and in winter they are sent for slaughter.

If chickens are kept all year round, it is important to build a warm chicken coop, taking into account the requirements for arranging lighting, ventilation, and heating. Insulating the building envelope from the cold helps to keep the interior warm.

Building requirements

The dimensions are provided so that there are 2 - 5 chickens per 1 square. If such dimensions are difficult to make, it can be populated more densely by building more perches and nests.

Requirements are put forward for the construction:

- the construction area is protected from the north wind, trees, shrubs are used;

- nearby equip walking in the form of a covered area;

- provide protection from rats, provide dry bedding.

The increased humidity in the hen house leads to lethargy of the pets, they cough and become inactive. Too hot room and dry air cause dehydration.

Types of warm chicken coops

The type of house is chosen based on the tasks that it will perform. Chicken coops are built stationary, temporary, collapsible, they are made portable or transportable on wheels.

Permanent, non-movable structures are suitable for winter maintenance. The building has an inner room, a fenced yard.

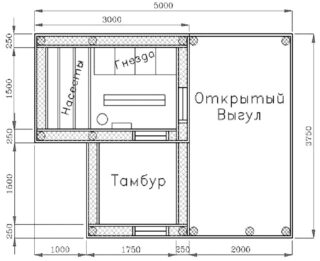

Drawings are needed for the construction of any house, they contain information about the sizes, layouts of elements, joints.

Popular dimensions of chicken coops for laying hens for the winter:

- for 20 chickens, they provide an area of 15 - 20 m², take into account the space occupied by feeders, other devices, drinkers;

- for 10 broilers, 3 - 5 m² is enough, for the same 10 individuals of meat, egg varieties, layers, 6 - 10 m² are required;

- young chicks are settled with 14 chicks in each square.

The height is made at least two meters, so that it is comfortable not only for chickens, but also for a person when cleaning and feeding.

Polycarbonate

The material can be installed as dividing internal partitions, lighting parts in walls or roofs. For the summer version, it is suitable for walls, but it is better not to build the winter one from it.

Material advantages:

- ease;

- strength, transparency;

- long term of work;

- resistance to temperature changes.

Areas made of polycarbonate can be easily wiped with a cloth, the surface does not accumulate dust.

From blocks

The hen house made of foam and aerated concrete blocks, shell rock keeps warm well in winter.Brick is used as small-sized elements. Building a hen house made of bricks takes longer than, for example, wood. Foam blocks and gas blocks have low heat conductivity.

Foam concrete does not absorb moisture, and aerated concrete is saturated with water. The difference in characteristics arises from differences in production, therefore, for the second type of blocks, waterproofing from soil and atmospheric moisture is provided. Block materials are considered non-toxic.

From cinder blocks

The stones are made of concrete, in which slag acts as a filler. This is a lightweight material compared to the crushed stone look. For the poultry house, the existing strength characteristics are sufficient to speak of good performance of the constructed building.

Cinder blocks conduct heat to a lesser extent than ordinary concrete, but in harsh climates they require external insulation.

A budget version of the chicken coop, when it is half buried in the ground, and on the surface from the south, the walls are brought out 0.5 m above the ground. Windows with double or triple glazing are placed in the fence.

Preparation for construction

The site is cleaned, the fertile layer is removed by 15 - 20 cm. According to the project, the axes of the building are marked out, pegs are driven in at the intersections. For digging a trench under the base, the stakes are taken out 1.5 meters along the line of the axis, so as not to remove the marks when digging. For marking, a level is used to set the depth of the trench.

The pegs are made from pieces of reinforcement with a length of 0.5 - 0.6 m or wooden slats are used. At the last elements, one end is rounded to make it easier to drive in. A nylon cord is used, which does not stretch when wet.

Materials for building a chicken coop

The chicken coop is built in winter in the form of an economical frame building. The walls are sheathed with moisture-resistant plywood, boards, and other types of panels.

Prepare materials:

- timber with a section of 100 x 80 mm for racks;

- timber 80 x 70 mm on the lower strapping, upper belt;

- braces, transverse are made from bars of 50 x 50 mm;

- boards for wall cladding - 20 x 120 or 151 mm, 25 x 150 mm are placed on the floor.

The roof is made of board, using corrugated board, slate, metal. The gaps between the posts can be laid with wall blocks. Self-tapping screws, bolts, steel brackets are used to join the tree.

The foundation is poured monolithic or prefabricated blocks are placed. For insulation, choose polystyrene, expanded polystyrene, mineral wool.

Tool for work

Concrete is prepared using a concrete mixer; buckets and shovels are used for filling. If done by hand, you need a mixing trough.

Carpentry works as a tool:

- jigsaw, hacksaw;

- grinder, chisel, plane;

- hammer, knife, pliers;

- drill, screwdriver, screwdrivers.

A tape measure, a square is used for measurement. Control the correctness of installation with a level, plumb line. For a drill, drill bits are prepared for wood, a screwdriver - nozzles for cross self-tapping screws. Cutting and grinding circles are placed on the grinder.

Step by step construction process

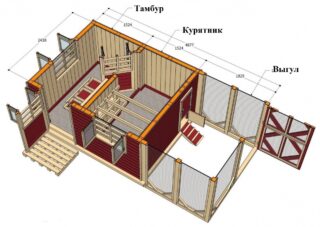

All work is carried out according to the project, the construction technology is observed. It is better to immediately provide a vestibule in order to reduce the flow of cold streams when opening, to save on heating.

In the process of building a frame chicken coop with insulation, the following works are performed:

- foundation device;

- erection of walls and roofs;

- floor installation;

- insulation of structures;

- arrangement of ventilation, artificial and natural lighting.

An important element of the building is the door, which must correspond to a person's height. The opening is provided inside the chicken coop.

Foundation device

The type of base is chosen depending on the size and type of soil, the material of the walls also matters. Wooden poultry houses are classified as light buildings, therefore, a columnar foundation is made for them or separate prefabricated reinforced concrete blocks are mounted in the ground.

For brick and block chicken coops, they make a foundation:

- monolithic slab (unstable soil);

- concrete tape.

The pillars are dug in at the corners and under the walls with a certain step. They are tied with a belt of beams so that they are not pushed out when the ground moves. The pillars are made of red brick, poured with concrete. In both cases, mesh reinforcement is used.

Erection of walls and roofs

Frame racks are placed along the lower belt of the foundation strapping, they are mounted strictly vertically. They are fastened to the beam with self-tapping screws, for strength they are connected with corners or brackets. At the top, the upper belt of beams is immediately fixed to give the frame stability.

Diagonal and angular braces are used to make the frame rigid. The cross bar will support the surface paneling. To build a winter hen house from OSB with your own hands, you need to cut the sheets to size, dock on the frame element, it is not recommended to do this in the air. Before installation, wooden elements are treated with linseed oil to reduce the effect of moisture, to prevent the development of rot.

The roof structure is:

- single-slope;

- gable.

The first model is chosen more often, since it is easier to carry out. The design with one slope is made removable or opening to ventilate in summer. One side of the racks is made higher in order to support the rafter beams at a slope.

For a gable roof, prefabricated trusses are prepared, which are fixed to the upper belt with a certain step. Along the rafters, lathing is performed with a rail of 20 x 40 mm, the step is chosen according to the type of coating and the degree of slope of the slope.

Floor installation

The logs are attached to the lower harness, the subfloor boards are stuffed from below. A layer of roofing material is installed to protect against soil moisture, insulation is laid on top. A vapor barrier is laid, then the flooring can be filled.

For the top layer, use:

- boards;

- clay;

- make a concrete base.

The latter type refers to cold coatings, so a layer of sawdust and shavings 10-15 cm thick is laid. The clay is mixed with straw, and a strong and warm surface is obtained.

The plank floor is considered the most suitable in terms of comfort and protection against heat loss.

Warming

Natural methods involve clogging the seams with sawdust with clay, tow. The method is suitable for southern regions and costs almost nothing.

They use inexpensive foam, which effectively insulates walls, floors, and roofs. Any insulation is best done outside in order to move the dew point closer to the outer surface and prevent condensation.

Expanded polystyrene is ideal, because with a small thickness it effectively protects from the cold, but it is not cheap. Mineral wool requires a ventilated space, which is created by installing a counter-lattice.

Ventilation arrangement

The standard method is to install a plastic, stainless steel pipe that is mounted under the ceiling. The air duct passes through the roofing cake, its head is raised above the roof by at least 1 meter. This is how natural draft is organized, the flow of air into the hen house goes through the cracks.

If the room is isolated from blowing out, a piece of plastic pipe is built into the wall at a level of 30 cm from the floor, the hole is covered with a steel mesh. Regulating dampers are provided to coordinate the air supply.

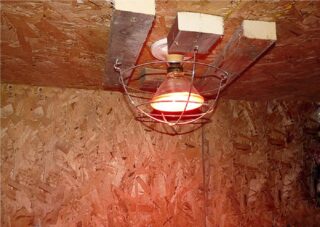

Organization of lighting

Heat escapes through the windows, but the glazed openings give the pets the necessary sunlight. Several glasses are placed to reduce heat transfer. The openings are protected from the inside with a metal mesh for safety. Foam is blown out along the perimeter of the frame, after drying, the excess volume is cut off, and covered with plaster.

The effectiveness of carrying eggs is maintained under illumination for 12-13 hours a day. In winter, the sun sets early, so lamps are installed. They are mounted at a height, using automatic devices for switching on and off in time.

Internal arrangement of the poultry house

The perches are made of a bar, the section of which is 30 x 30 or 30 x 40 mm. The edges are rounded so that it is convenient for the chickens to grip the stick with their paws. Trays for waste are placed under the perch. They put feeders and drinkers for poultry against one of the walls

The rule for setting the roost:

- placed in impassable, least active areas;

- the distance is made no more than 30 cm from each other.

The length is made so that the village is 10 - 15 chickens (3.0 - 4.5 m).

Nests are open and closed. The second option is preferable, but it is difficult to construct. Open nests (30 x 40 cm) are made of plywood, planks.

Heating the poultry house

Most often, electricity is used. They use the method of fan heaters, infrared emitters, install oil heaters. The first type is acquired with a programmed shutdown on time or when a predetermined temperature is reached.

IR heaters heat the surrounding objects, not the air. They are hung over nests, perches, and placed at floor level. If chickens are cold, they crowd around them, and it can be cold in the house.

Oil radiators consume a significant amount of energy and are therefore considered uneconomical. Pipes from the boiler are carried into the chicken coop, but this is rare. They put a small brick oven, or put a potbelly stove on the wood.

Walking yard

In winter, birds are released into fresh air for a short time at temperatures down to -12 ° C outside, if there is no wind. The height of the covered shed of 1.2 - 1.5 m is sufficient, but it is necessary to ensure the convenience of service to the owner. It is recommended to build a chicken coop right away with a walk, so as not to worry about it with the arrival of spring.

The corral is a frame lined with iron mesh on all sides. It is better to make the floor in order to insulate the base, to prevent digging up the surface. Shavings are laid, which are removed after getting wet. The roof is made of tilt, slate, boards.