Single-tiered and multi-tiered benches in the steam room are made for relaxation while taking bath procedures. The bath shelf is made of wood that does not emit harmful components into the environment; conifers are not used. Types with low thermal conductivity are used, the surface of which does not overheat at high temperatures in the steam room, so as not to burn the body upon contact.

- What are shelves

- Dimensions and shape

- The location of the shelves in the steam room for comfortable movement

- Material selection

- Alder and black alder

- Larch

- Aspen

- Linden

- Maple

- Poplar

- Bath Shelf Manufacturing Guide

- Frame fabrication

- Installing racks

- Installing the supporting structure

- Grinding the finished structure

- Sauna shelf processing

- Wood care tips

What are shelves

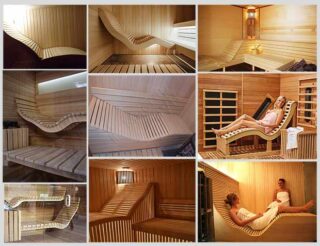

Single-tier benches are made portable, made stationary, with or without backs. The height is selected so that the knees of a person in a sitting position are at the level of the pelvis. Greater height will cause the legs to dangle in the air without support, which is inconvenient for the visitor.

Bunk racks increase the functionality of the furniture, such units are attached to the walls, and the shelves on them are made removable for drying. The second floor is accessed by a fixed or retractable staircase, or the benches of the first level are used.

Stepped bath shelves in the steam room are used in small rooms, while the tiers are placed one above the other. If the work of a bath attendant is envisaged, a separate bench is prepared for his procedures, the height of which is taken at the level of 70 - 90 cm from the floor.

Dimensions and shape

The lower shelves are made in the form of a bench with a seat, a back, four legs and reinforcing crossbars. Portable benches with two supports and without a backrest are unstable and fail quickly. The seat boards must be secured at intervals that are necessary for water drainage and ventilation.

The height of the first level is made 35 - 50 cm, the second shelf is placed so that, sitting on it, a person rests with his feet on the previous floor. Lying down, the visitor must stretch his legs along the length, therefore, the minimum size is 1 m 50 cm, but if possible they do more.

The size in width for sitting in a Russian bath is made 50 - 60 cm, in a dry seated sauna, 40 - 50 cm are provided. For lying, the width according to the instructions is taken so that a person in the supine position can freely put his hands along the body. Usually a width of 90 cm is sufficient.

The location of the shelves in the steam room for comfortable movement

Single-tier benches are placed between opposite walls or an angled structure. Typically, these benches are made portable to take them out into the air.

When assembling high-bay racks, take into account the distance to the oven so as not to burn yourself. Sometimes, when jumping off, a person can lean forward with the body. In spacious steam rooms, they use the option of placing one bench opposite another, while the distance should not be less than 80 cm.

Stepped structures increase the functionality of the steam room so that the visitor can choose the degree of heating. At high heights, the maximum possible width of the shelves is made.

Material selection

For the installation of the frame, wooden lumber is not suitable immediately after cutting and sawing, since the products from them will not stand for a long time. Boards from wet trunks warp when heated, swell. Reject material with dropping out knots, spots of blue and blackness on the surface.Do not use boards cracked in length and width.

The lumber must have the correct geometry. Curved, bent bars with different thicknesses along the length after heating will change their shape, give distortions of the structure.

Good breeds to collect in the sauna are:

- larch;

- plain and black alder;

- aspen;

- Linden;

- maple;

- poplar.

The wood should be of low heat conductivity, hardness and sufficient density. Conifers emit resinous substances, so they can be used for external walls, roof structures, but not inside the bath.

Alder and black alder

Black alder wood has a distinct color difference between the inside of the trunk and the outside. A beautiful combination is used to develop an original design. The breed of gray and black alder is ideal for arranging shelves in a bath, since it almost does not absorb water. Low hygroscopicity prevents the material from cracking in frost when the bath is not heated.

During operation, the material does not deform, does not dry out, and has a low heat conductivity. The tree shows anti-putrefactive and antibacterial properties. The lumber after assembly can be left untreated with chemicals for durability. The material breathes, so it can regulate the humidity in the room.

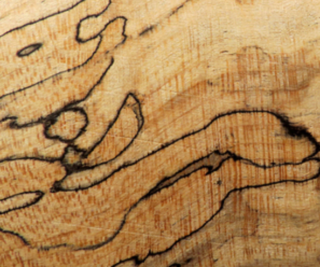

Larch

Wood of this type is distinguished by its durability and is second only to oak in terms of performance. The rock does not react to high humidity, does not deteriorate when used in conditions of high temperature and steam saturation.

The cut shows a beautiful pattern of fibers and annual rings. For the bath, about twelve shades are used, which are represented by a range from light brown color with a reddish tint to all varieties of dark red.

Larch is used for the manufacture of seats, to build a frame, to sew up the surface between structures. The benches keep pleasant warmth and do not overheat, fungus and mold do not develop on the boards. When cleaning from dirt, sandpaper is used so as not to use chemicals.

Aspen

The surface of the lumber is always smooth, so it is impossible to get hurt, get a splinter. Wood is characterized by low density and strength, therefore, seat elements are made from it, which have reliable fastening and support.

It is believed that aspen absorbs negativity, therefore, in a steam room with such elements, there is a cleansing of stress and disease. The products are devoid of any smell, do not emit toxic elements into the surrounding space. The homogeneous structure of the tree allows it to be processed in different directions, it is easy to saw and drill. The color and pattern on the surface remain unchanged after long-term use.

Linden

The wood does not conduct heat, therefore it does not pose a danger in terms of getting burned. The scent of linden is considered the most pleasant of all other species, while the wood promotes strong perspiration. The grain pattern on the section has a blurred outline, the color ranges from light yellow to brown or reddish tint, there are greenish spots and stripes.

The wood is soft, low elastic, not heavy, requires regular intensive drying. In a humid environment, a fungus starts, rotting begins. It is easy to process by hand, but it is difficult to get a perfectly flat surface. If there is contact with metal, gray spots appear in the area of contact, and the iron begins to rust quickly.

Maple

A fine-pored tree is classified as a valuable species, the annual rings are clearly distinguished on the cut, but the sapwood and the core are almost the same in color. The material of medium density and weight has a yellowish, whitish and pinkish color. Differs in sufficient strength and resistance to warping. With regular exposure to the sun, it changes color, becomes darker.

In the bathing industry, maple boards are considered as a cheaper likeness of linden lumber. Despite its lower decorative qualities, maple is superior to linden in compressive and flexural strength. On the benches, even at high humidity, there are no marks and dents from impacts. To increase the resistance to decay, various impregnation-antiseptics are used.

Poplar

Soft wood is easy to saw and planed due to its not too dense structure, but the numerous fibers of a viscous rock are difficult to grind. The surface is characterized by a yellow-brown or brownish tint without a pronounced grain pattern.

Requires mandatory impregnation with preservatives before installation in order to increase resistance to water, steam, heat. In a sauna environment, such procedures are not welcome, since then these substances will seep into the atmosphere after the injection of heat and water vapor.

In terms of strength, poplar has weak characteristics, therefore, in the steam room, lightly loaded parts are made from it. The surface almost does not resist impacts, which is why the breed is rarely used for the manufacture of bathroom furniture, in comparison with other types.

Bath Shelf Manufacturing Guide

Before starting work, a detailed drawing is drawn up. It indicates the overall dimensions and dimensions of all parts. The joints are developed, the nodes are drawn, then they proceed to manufacturing.

A step-by-step instruction consists of separate processes:

- frame assembly;

- installation of racks;

- installation of the supporting structure;

- grinding the finished rack;

- processing of shelves.

Correctly assemble the structure using wooden fasteners, for example, dowels, wedges. The use of metal bolts with nuts, brackets and anchors is allowed. They are installed so that the users of the bath do not directly touch the steel hardware.

Frame fabrication

The frame is a bar base to which the flooring elements are fixed. Shop shields are fixed tightly, or made collapsible.

Common wireframe schemes:

- the base is made of vertical supports in the form of bench legs, for the connection of which jumpers are used from thick slats;

- the frame is made in the form of a kosour staircase, then the shelves of each tier are fixed to it in the form of steps;

- the frame, as such, is absent, and the benches are attached to the vertical surfaces of the walls like shelves in a railway carriage.

The details of the structure are developed in the drawing, then the elements are cut out, mounted in the required position. The racks are reinforced with jumpers, struts, diagonals.

Installing racks

For upper benches use:

- up to 4 - 6 racks with a height of 1.1 - 1.15 m;

- the section for them is chosen 50 x 100 or 100 x 100 mm;

- for fastening long anchors or dowels with screws (from 20 cm).

For racks, the bars do not need to be sanded, but the material should not have chips or cracks. A gap of 1 - 2 cm is left between the wall so that air can circulate. For the gap between the wall and the rack, insert a board of the required thickness. The correctness of installation is checked with a building level or a plumb line.

Installing the supporting structure

The upper part of the bearing run is made with a section of 50 x 50 mm, and is fastened across the future shelf in increments of 0.5 - 0.6 m.The size of the indentation depends on the thickness of the boards (3 - 6 cm), it is calculated so that the elements do not sag under the weight person.

The bars are fixed with a slight slope from the wall for water to drain (1 - 2 °). Fasten them with wooden pins or steel screws with a galvanized layer. For the couch, boards with a width of 100 - 250 mm are used, they are placed with an interval of 1 - 2 cm. As a standard, the elements are arranged in length, but they can be placed along the width of the deck.

The lower benches are made on a separate frame for ease of movement. First, a frame of legs and crossbars is placed, then it is covered with planed and polished boards.

Grinding the finished structure

The operation is necessary to eliminate the raised pile that could appear during the assembly process. Fibers appear if softwood species have been selected for the job.

Grind the surface:

- manually;

- using an electric tool.

For manual work, you will need emery No. 60 - 240, which is fixed on a special machine, or nailed to a wooden block. The coarseness will depend on the thickness of the fibers. In the second version, a grinder is used with a set of grinding wheels for wood. Regardless of the method, the work is carried out moving in the direction of the pile. If you do the opposite, chipped stripes and notches will appear on the plane.

Sauna shelf processing

For impregnation from moisture, bugs, microorganisms and fire, non-toxic preparations on a natural basis are used. Organic products are deeply absorbed into the material. Standing out in the steam room space under the influence of heat and steam, such ingredients do not pose a danger to human health.

Impregnations are applied in 2 - 3 layers, each is expected to dry for 5 - 6 hours before applying the next one. Linseed oil is often used or combined with wax. Such a composition is expensive, but processing is enough for a couple of years, then after drying, the products are impregnated again.

Wood care tips

Removable shelves and lower benches are taken outside in clear weather to dry from moisture. In winter, it is necessary to heat the room to raise the temperature and reduce dampness. There must be ventilation in the bath, it is better to put a forced version with fans for effective air exchange.

Laundry soap is used to wash the benches - it is not toxic, it does not spoil the plane of the shelves. Planks, rungs, racks damaged by microorganisms are promptly removed so that mold does not grow in the steam room and putrefactive processes do not develop.