Baths are built in the form of a small steam room in a private yard or large complexes with gyms, swimming pools, saunas, solariums are organized. The correct bath from A to Z is built from materials that can be used in high humidity and heat conditions. It is necessary to competently draw up a project and carry out construction and finishing work in compliance with a special technology so that people feel comfortable when accepting the procedures.

- Choosing a place for building and planning a bath

- What material to build a bathhouse yourself

- Materials for insulation and vapor barrier

- Decoration Materials

- Drafting a project

- What is the optimal bath size

- Foundation filling and waterproofing

- Wall erection and roofing

- Water supply and drainage

- Ventilation installation

- Installing the oven and shelves

- Interior and exterior decoration

Choosing a place for building and planning a bath

More often, the building is located in the depths of the suburban area or the courtyard of a private house. Construction near a natural reservoir is considered optimal, but this option is quite rare. Not far from the bath, you can equip an artificial pool to plunge into after the heat.

An elevation or a gentle slope is chosen for construction in order to be able to make drainage, organized drainage of water by gravity to the sump. No roots of bushes and trees are left on the territory, because in conditions of humidity and temperature conditions, they will begin to germinate, destroy the soil at the base and the foundation of the bath.

Special sanitary standards have been developed that regulate the location of the bath in the courtyards of a city or village.

Primary requirements:

- buildings heated by the "smoke-free" method without a chimney are placed no closer than 12 m to the house;

- structures with a chimney device are located at least 6 m;

- to the source of drinking water - no closer than 8 m, and the sewer network is taken out in the opposite direction from it;

- to the fence - 1 m, the road on the street - 5 m;

- to sheds, utility blocks - 6 - 12 m (the distance is determined by the material of the walls).

Vegetable gardens, gardens should be no closer than 15 m. The windows of the bathhouse are made from the south or west side, so that there is more light inside, and in the evening natural light remains longer.

What material to build a bathhouse yourself

The durability of the bath complex depends on the choice. The properties of building materials, the degree of their environmental friendliness determine the internal comfort and the state of the microclimate.

When choosing, take into account the requirements:

- high performance of protection against heat loss;

- the degree of moisture absorption, hydrophobicity;

- reliability, durability, strength.

Modern technologies allow the use of building materials with different qualities, but when choosing, you need to take into account their cost. The appearance of the structure should be combined with the landscape of the site and other buildings.

Before determining the stages of building a bath with your own hands from foundation to roof, you need to choose building materials for the walls.

Most often used for assembly:

- wooden lumber such as logs, beams, frame blocks, boards;

- expanded clay block, cinder block;

- gas block, foam block;

- Red brick;

- a natural stone.

Wood is ideal because it has low heat conductivity. Profiled timber reduces shrinkage and lasts longer. Block walls also retain heat well, and bricks are used for a long time, but they are more expensive and increase the construction time.Foam concrete does not allow moisture to pass through, and aerated concrete is saturated with water, therefore, it requires a protective layer of waterproofing.

Materials for insulation and vapor barrier

Wooden structures are caulked outside and inside with tow, jute. External finishing like a hinged frame allows you to install an additional layer of insulation.

The types of insulator are used:

- Styrofoam;

- extruded polystyrene foam;

- foil insulation;

- mineral, stone, wool, slag wool.

Mineral wool is saturated with drops of condensate, therefore, it requires a waterproofing device and a ventilated gap, which is equipped with a counter lattice. As a vapor barrier, a special canvas is installed that allows air to pass through only in one direction. Waterproofing is provided with roofing felt, roofing felt, wind protection - with polyethylene.

Decoration Materials

The bathhouse is sheathed inside with wood, which creates comfort better than other types. For walls, benches, rocks are used that do not heat up in hot conditions so that people do not get burned on contact. The floors are made of wood or concrete. The second variety is covered with ceramic tiles with a corrugated surface. Before you put a wooden bath with your own hands, you need to pre-treat the material with antiseptics and anti-fire agents.

For outdoor decoration use:

- natural lining or on the basis of MDF, block house;

- metal, vinyl siding, plastic;

- professional sheet;

- ceramic plate materials;

- front brick;

- warm plaster.

The roof is covered with metal tiles, corrugated board, ondulin, slate.

When choosing, they do not use freshly cut and sawn logs, even if they are sold at a low price. After the construction of the felling, the forest shrinks not too fast, which can last more than a year. Use wood with a moisture content of no more than 18%. It is impossible to use cheap types for construction and decoration; in order to save money, it is better to reduce the size of the interior, remove the terrace, combine the dressing room with the dressing room.

Drafting a project

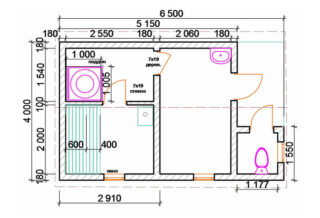

Projects take standard ones or compose themselves. The task is to make an accurate drawing and calculation for the construction of walls, roofs, foundations, take into account the location of bathroom furniture, provide for a communications device.

The project shows the place of installation of the stove, the type of ventilation, the way of draining the effluents, the laying of clean water pipes. Drawing up drawings is not a difficult process, the main thing is to comply with the recommended dimensions, sanitary standards for the location of equipment, safety requirements. According to the drawing, it is easier to calculate the need for materials, make changes to the layout, if necessary.

What is the optimal bath size

The project takes into account the dimensions of the steam room, dressing room, washing room, the overall dimensions of the building will depend on this. The building of the Russian bath can be of minimum width and length, for example, 2.1 x 2.0 meters. Such a room has a small dressing room, the rest of the area is occupied by a double room, where there is a stove, a bench for lying or sitting.

A building with dimensions of 3.0 x 4.0 meters is already planned with a shower and a small place for rest. To increase the seats, multi-tiered shelves are made, the seats are placed in the form of the letter G, while observing the norms of the gap between the shelves. The height of the ceilings in the bath building rarely exceeds 2.3 m. In small buildings, the steam room is combined with a washing room.

Foundation filling and waterproofing

After drawing up the project, the foundation is built. The depth is laid according to the design calculation, taking into account the height of the ground fluid, the degree of freezing of the earth.

Sequence of work:

- trench marking;

- earthworks, bottom cleaning to zero;

- drainage cushion device;

- installation of formwork, installation of waterproofing from three layers of roofing material;

- reinforcement laying.

They try to pour concrete in one day. If it does not work out, they leave inclined joints in order to continue pouring tomorrow. Concrete gains 100% strength on the 28th day, the formwork is dismantled on the tenth day.

Wall erection and roofing

On the surface of the foundation, 2 - 3 layers of roofing material are placed on mastic to protect the walls from moisture. For the walls, they take a beam of 150 x 150 mm, 150 x 180 mm, metal studs, brackets, bolts, wooden pins are used for the connection.

Step-by-step construction procedure:

- separate wall crowns are built in the form of docked bars and logs;

- thicker lumber is used for the first crown, further construction is carried out with thinner elements;

- the voids are clogged with felt, tow;

- for arranging the roof, a Mauerlat is mounted on top of the walls (a bar along the perimeter).

Mauerlat is insulated with roofing material, fixed with wire to anchors installed at the top of the walls. The rafter legs are supported on it, on top of which the crate is mounted.

Water supply and drainage

The method of laying the water supply depends on the use of the bath in winter. Pipes are laid in the air, rubber or plastic elements are used, if the water is drained for the winter so as not to burst when freezing. During winter operation, insulated pipes are led in the ground, taking into account the depth of soil freezing.

Drainage of water can be through a pouring floor, where the liquid goes directly to the ground or drainage pad. A solid inclined floor assumes the device of a receiving bowl for liquid, a redirection of the flow into a cesspool. A multi-chamber sump is also used, or pipes are connected to a common city, village sewage system.

Ventilation installation

There are two types of ventilation in the bath:

- natural air exchange;

- forced flow of streams.

In the first version, air is removed through built-in channels in the walls of the bath, sometimes suspended air ducts are built from a galvanized pipe under the ceiling. It is important to ensure the supply of fresh air; for this, small vents or supply channels are provided.

To speed up the air exchange, fans are installed at the inlet to the air ducts. This method is more effective, but requires electrical power supply.

Installing the oven and shelves

The dressing room is considered the best location for the heating center, when a channel for heat supply is brought into the steam room, and the firebox is made in another room. As a result, there is no soot, soot, fuel debris in the steam room. To create steam, a stove is placed in the room to water the hot stones and get thick steam.

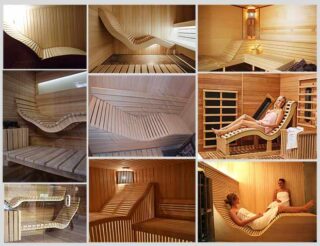

The shelves are designed so that it is comfortable to sit on the first tier. The second levels are also reassigned for sitting or lying down. The width for sitting is 60 cm, in the sauna they make 45 - 50 cm, lie comfortably on a bench 90 cm wide. The shelf is made along the length so that you can stretch your legs. The minimum length is 150 cm when the knees are slightly bent. If possible, take into account the height of the person and make the size longer.

The furnace is selected according to power, while taking into account the material of manufacture.

The following types of stoves are used:

- brick;

- metal;

- cast iron.

A too powerful unit will lead to overheating of the air, while the stones do not warm up enough. A low-power firebox works for wear and tear, it will not last long.

Brick and cast iron stoves are massive, they need a solid foundation, they keep heat well. Metal assemblies are quicker to install, but steel units cool quickly, so you need to regularly add fuel.

Interior and exterior decoration

For cladding rooms with high temperatures, it is not recommended to use conifers, since they emit resinous substances that are harmful to breathing. For walls, floors, ceilings, benches, larch, birch, fir, aspen, cedar are used.

The outer cladding is often combined with insulation, therefore, a frame is provided as a hinged facade in order to lay an insulator layer. Warm plaster is used when styrofoam or expanded polystyrene boards are glued to the wall surface. A plaster plastic mesh is mounted on the insulation, then a layer of putty with a smooth or textured surface for painting is performed.