Traditions of a Russian estate implies the placement of utility rooms separately from a residential building. A do-it-yourself timber bathhouse, in addition to its direct purpose, can serve as a resting place, being at the same time an element of the design project of the site. It is important to follow the rules of wood construction in order to extend the life of the building and spend a minimum of time on subsequent maintenance.

- Advantages and disadvantages of the material

- Seat selection

- Construction stages

- Which timber to choose

- Project selection and construction stages

- Foundation construction

- Features of mounting the lower rims

- Walling

- Roof construction

- Floor installation

- Installation of doors and windows

- Internal and external finishing

Advantages and disadvantages of the material

The positive consumer properties of wood speak in favor of assembling a bath from a bar:

- Environmental friendliness - even at high temperatures, wood does not emit chemically hazardous substances, which are almost always used in the manufacture of artificial building materials.

- Relatively low price of timber and small costs for the arrangement of the foundation.

- Good thermal insulation, allowing you to save on insulation.

- The tree dries quickly, water vapor is removed both by ventilation and passing through the walls.

- Attractive appearance of the new building and the ability to sheathe the walls as the wood darkens.

- Long service life before overhaul, subject to the construction technology.

- Special microclimate and natural aroma of wood, which is appreciated by lovers of the bath.

- High construction speed, in contrast to stone buildings, the walls of which need high-quality finishing.

At the same time, it is necessary to know and take into account the disadvantages of baths from a bar:

- The shrinkage of the walls lasts up to six months, at this time windows and doors are not inserted - the frames can lead, the glass can be destroyed, and the doors can jam.

- Fire hazard.

- Assembling a bath from a bar requires skills and is difficult for beginners.

- The need for periodic maintenance of wooden walls from signs of decay and fungal growth.

The construction of a bath from a bar begins after weighing all the positive and negative sides, comparing the prices for building and finishing materials, and carefully choosing a project.

Seat selection

The correct place for a bath should meet fire and sanitary requirements, as well as be conveniently located. The minimum distances are specified in the Fire Regulations and SNiP 30-02-97 *, which determines the planning and development of the territories of horticultural dacha associations of citizens. On the basis of these documents, standards are also developed for settlements, which may differ for each region or city.

On your site, a wooden bathhouse can be built into a residential building or located 8 m from it, if it is a separate building.

The distances between the log bath and the buildings in the neighboring cottage should be:

- from 10 m, if the house is completely made of non-combustible material;

- at least 15 m to buildings made of combustible materials.

You should retreat from the red line of the streets by 5 m, and from the red line of passages by 3 m. From the fence separating the dachas, they retreat by 1 m, the distance is considered not along the wall, but along the roof overhangs. The slope should be towards its site. If the water flows towards the neighbor, then they retreat from the fence by 1.5 meters.

It is important to maintain the recommended distances.If there is no disagreement at the present time, over time, new neighbors may appear and require the demolition of the building.

In addition to the requirements of regulatory documents, when choosing a place, they try to take into account:

- Convenience of moving between the house and the bath. It is desirable to make the distance as small as possible.

- Minimum costs for laying communications.

- Possible damage to the wood of the crowns and walls in low places of the site, where the high moisture content of the soil constantly creates snowdrifts.

- Distance to trees that may be affected by dirty runoff containing detergents.

- The need for a drainage pit and the presence of a well on the site. The distances between them should not be less than 15 m.

In addition, a distance of at least 4 m is provided from the drain septic tank of the bath to the neighboring area.

Construction stages

The construction of a bath from a bar with your own hands is carried out by the method of phased construction.

Algorithm:

- Selection and purchase of material.

- Project selection and drawing up drawings.

- Arrangement of the foundation.

- Erection of the walls of the log house.

- Roof construction.

- Floor installation.

- Installation of windows and doors.

- Internal and external decoration.

At the design stage, the type of heating is provided. The arrangement of ventilation and chimneys depends on the choice of a stove (wood or electric).

Which timber to choose

The bar is a round timber processed from all sides.

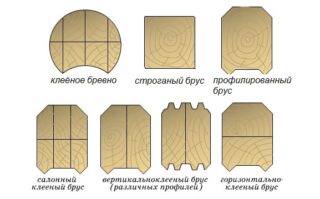

Depending on the manufacturing method, the timber is:

- sawn solid (edged) - the log is cut from all sides, giving a square or rectangular appearance in the section;

- one-piece profiled - the upper and lower parts have a locking device, the ridges of one bar enter the grooves of the other;

- glued profiled, consisting of several boards glued under the pressure of the press;

- glued insulated - between two boards facing inside the house and outside, there is a heater, most often polystyrene.

The first option is the cheapest, since it requires minimal production costs. At the same time, for high-quality insulation, you will have to maintain the quality of caulking every year.

Solid timber is prone to warping and cracking, especially in winter, and a rough surface will require finishing. The geometric dimensions may differ by 1–2 cm, which spoils the appearance of the wall.

The profiled type, in addition to the manufacture of ridges and grooves, is subjected to factory planing, due to which the building turns out to be beautiful and will require decoration only after 4–5 years of operation.

Glued profiled timber is an expensive building material, but this drawback is compensated by the fact that the products are not very susceptible to warping, have precise geometric dimensions, and serve for a long time. Time-consuming fitting is eliminated during construction.

The raw material for the production of timber is a wide variety of wood: oak, pine, spruce, larch.

Despite its long service life, oak is not the best option for a bath. Over time, wood cracks, which deteriorates the appearance and consumer properties, timber roads.

Larch does not rot, it loses its attractiveness, but it is not cheap. The best option is to use this breed for the manufacture of the lower rims. They are constantly in contact with the ground, therefore, are subject to accelerated destruction.

Pine is the best option in terms of price / quality ratio.

Spruce is not more expensive than pine, but it starts to rot faster.

The best option seems to be when the lower rows are made of larch, and starting from 3-4 crowns, pine begins to be laid.

Manufacturers often produce products according to their specifications, therefore, products of different quality may have the same grade.

Choosing a bar in order to build a bath yourself, material is rejected that has:

- more than 2 knots ranging in size from 20 to 50 mm per linear meter;

- cracks up to 4 mm in length over 500 mm;

- traces of wane, rot, blue wood and unevenness;

- deviations in geometric dimensions more than 3 mm.

When buying, pay attention to storage conditions. The material should be placed under a canopy that protects it from precipitation and direct sunlight. It is advisable to find an opportunity to measure the moisture content of the tree, it should not exceed 22%.

Project selection and construction stages

It is important to decide before starting the design which timber will be used at the construction site.

If saving money is important, choosing optimal wall sizes can help reduce waste when cutting timber.

In the simplest case, premises are provided for:

- vestibule;

- a dressing room, sometimes combined with a dressing room;

- washing;

- steam rooms.

For structures of increased comfort, they make a recreation room, a dressing room, a washing room, a furnace. For recreation in the summer, they equip a veranda.

In the project, special attention is paid to the foundation of the bath, which may be different depending on the type of soil, the height of the groundwater.

Foundation construction

The foundation for baths from a bar can be:

- slab;

- tape;

- columnar;

- pile.

A solid concrete slab underneath the entire building is used on wet, heavy soils.

A strip concrete foundation is often redundant for light timber structures. Among the positive qualities, the ease of arrangement stands out. The disadvantage is the increased costs for reinforcement and concrete.

Pillar and pile foundations are applicable on heavy soils where swelling is possible. They are easiest to make at the required depth below the freezing of the soil.

For a columnar foundation, they dig a hole to a depth of about 1.5 and fill it with a concrete mixture. Another technology can be used to stack columns of concrete blocks or red ceramic bricks. It is important to make accurate markings and bring the top of all supports to the same height.

In pile versions, wooden or metal pillars driven into the ground are used as supports.

Screw piles, which lend themselves to manual installation, are becoming popular. The foundation can be assembled in 1-2 days, paired with one assistant. The top of the screw pile is cut off with a grinder and a support platform is welded to which the first crown is attached.

Features of mounting the lower rims

It is important that the first (lower) crown of the bath is reliably protected from moisture that gets on the timber from the ground or with drops of precipitation. Roofing material or other roll materials are used. Concrete bases are covered with a layer of spread-type waterproofing.

For the first crown, it is advisable to use a bar of a larger section than the one that will be in the walls.

Details must be treated with an antiseptic and fire retardant.

It is not necessary to fasten the first row to the foundation; under the weight of the building, the timber will be reliably pressed to the base. However, for ease of installation - so that the beam does not move when installing the second crown - threaded rods and threaded metal anchors are used.

Walling

Builders distinguish two ways of building walls: "in the corner" and "with the remainder". In the first case, there are no protrusions. The method is more suitable for self-repetition - it is easier to perform connections this way.

Wall connections are carried out:

- in half a tree;

- in a bandage with a root spine;

- on dowels.

Which method to choose depends on the carpentry skills and the availability of special tools.

As the walls rise, the timber is fastened with dowels.

Roof construction

For baths up to 4 m wide, it is enough to make a pitched roof. For buildings, a gable is chosen wider.

The arrangement begins with the installation of the rafter system. A bar with a section from 40x60 mm to 60x100 mm is used. The section depends on the material and weight of the flooring. A flooring is nailed on top of the rafters, which serves as the basis for the topcoat.

How to cover the bath depends on financial capabilities and the need to maintain a single style with the rest of the buildings. Use asbestos-cement metal or soft slate, metal siding, metal tiles or soft roofing in the form of tiles or sheet materials.

Floor installation

In the baths, special attention is paid to the floors. They should not let through drafts and be cold. At the same time, ventilation is provided to prevent premature decay of the boards.

The options for arranging the floor may be different:

- concrete, covered with tiles or wood on logs;

- solid wood;

- leaking wood for steam rooms and shower rooms.

Concrete floors are arranged on strip and slab foundations:

- The surface is cleaned of debris, vegetation residues.

- A 10-15 cm layer of expanded clay is poured in or expanded polystyrene is laid.

- Pour in a fine screed.

- The floor is finished with ceramic tiles or logs are installed, which are covered with boards.

A solid wood floor consists of a rough and a finish coating, which are nailed to the logs.

The order of the layers, starting from the ground:

- waterproofing

- rough floor from the board;

- waterproofing;

- insulation;

- vapor barrier;

- finishing floor made of grooved boards.

In places with a large volume of flowing water, lattice coverings are arranged instead of solid boards.

Installation of doors and windows

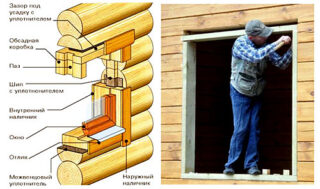

Depending on the properties of the building material and the quality of the assembly, the final shrinkage of the log house occurs within 5-6 months. At this time, windows and doors are not inserted.

Installation of window frames and door frames is carried out with screws or nails. Leave a gap between the web and the strapping of at least 5 mm on each side. If this is not done, then jamming will occur when wet from steam and moisture.

Internal and external finishing

Finishing is carried out only after final shrinkage. For internal walls, use wooden lining or tiles laid on drywall.

The outer walls are caulked beforehand to exclude drafts. Any materials are suitable for exterior decoration: siding, block house, ventilated or wet facade.

Along with the finishing, engineering communications are being installed. Pay special attention to wiring. Under the lining, wires are laid in metal pipes. The option of external wiring in electrical boxes or on dielectric insulators is possible.