Siding is a building material that is designed to protect the walls of buildings and structures from the effects of the external environment (sun, wind, rain, snow, etc.). It is often used to decorate the facades of individual residential buildings.

Varieties of siding and its characteristics

In the construction market, siding occupies a separate, fairly voluminous niche. The range of wall panels is striking in its diversity. The industry produces siding of the following types:

- wall panels designed to protect and clad facades from climatic influences;

- facing panels that do not require additional finishing;

- strips with a thickness of 1-10 mm, having a length and width in the ranges from 2 to 6 and from 10 to 50 millimeters, respectively.

The following materials are used in the manufacture of siding:

- vinyl;

- wood;

- metal;

- fiber cement.

According to the fastening and type of installation, siding is divided into vertical and horizontal.

There are also plastic panels, the form factor of which imitates a log or natural stone.

Characteristics

Depending on the material of the base, the characteristics of the siding differ:

- Wooden siding contains wood fibers, which are pressed with a special resin under the influence of high temperature. Outwardly, the material resembles a real tree. However, the technology used for its manufacture is rather complicated and costly, as a result of which the siding has a high price. In addition, it is highly flammable, so it is not particularly popular with the population.

- Metal types of siding (steel and aluminum) differ in a variety of colors. Steel siding is a heavy material coated with polyester or special powder coatings. It is distinguished by its special strength, long service life and resistance to sudden changes in temperature. Therefore, it is used to decorate the walls of industrial buildings. Aluminum panels are lightweight, which makes it possible to decorate with it even the ceilings of industrial workshops and office premises.

- Vinyl siding is the most popular material, characterized by a low price, ease of installation, and the ability to mask defects in the surfaces to be coated.

- Cement siding is a fire retardant material made from cellulose and cement fibers. It resembles boards in texture. They are used for cladding public buildings (clinics, schools, kindergartens, etc.).

Vinyl siding should not be confused with clapboard. Vinyl lining is used only for interior decoration.

Advantages and disadvantages

Compared to other materials, siding has a number of undeniable advantages:

- presentable outdoor look;

- long service life;

- versatility;

- ease of installation and handling;

- withstands any climatic conditions, including sudden temperature changes;

- does not rot;

- does not require expensive repairs.

Vinyl siding is flammable and, when melted, releases substances harmful to the body. When performing installation work, metal siding requires compliance with certain safety rules and the presence of overalls, gloves and goggles.These types of panels are susceptible to mechanical stress, and the defects that have appeared can no longer be corrected. Wood and wood types of siding have a short lifespan.

DIY siding installation

The main advantage of siding is simplicity and ease of installation, which does not depend on the base material and does not require any special skills. Do-it-yourself siding installation on a brick house will require the homeowner to only carefully follow the sequence of all the work.

Tool

- Personal protective equipment (glasses, gloves, etc.).

- Layout tools: tape measure, a special template for cutting panels, as well as construction and rope levels.

- Cutting tools - grinder, hacksaw and metal scissors, cutter knife, hand saw with an abrasive disc. A grinder disc at high speed can melt the vinyl panel at the cut.

- Fastening tool: screwdriver, screwdriver, awl.

In addition, you will need: a hammer-nailer, pliers, crimping pliers, a notch cutter, a special puncher and a device for dismantling the panels.

A device for dismantling panels, a special mold, a perforator and a notch cutter belong to the category of special tools and it is not easy to find them in building materials stores.

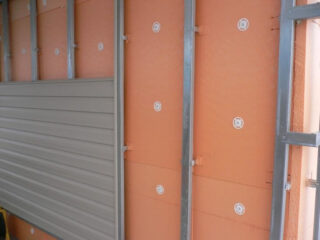

Siding frame and wall preparation

High-quality installation of siding cladding on the walls of a house is impossible without a properly installed frame (lathing). Its elements can be made of wood and metal profiles, which are used when decorating walls with plasterboard. To ensure a presentable view of the entire building, many manufacturing companies include instructions for installing siding on a wooden house with their own hands in the delivery kit.

It is up to the homeowner to choose the material for the frame.

- Wooden lathing is cheaper.

- The metal profile is much stronger and more durable.

- The tree must be treated with an antiseptic to protect it from decay. When dry, the crate can warp, which will affect the quality of the entire finish.

- The metal profile does not change its size and does not require additional processing.

Before installing the crate (frame), the wall must be prepared:

- Dismantle all the elements of the facade (drainage systems, door and window frames, drains, etc.)

- Defects on the wall are sealed with mortar or facade putty.

If the siding is installed horizontally, the frame elements are mounted vertically. It is necessary to mark the wall by drawing vertical lines every 0.5 m. In the corners, such lines are applied without fail. Every 0.5-0.6 m, direct suspensions are installed and fastened with self-tapping screws to plastic dowels. Along the perimeter of windows and doors, direct suspensions are also installed with a step of no more than 50 cm.

Having finished the installation of direct suspensions, they proceed to the installation of insulation. For this, board materials (expanded polystyrene, mineral wool, etc.) with a thickness of 50-60 cm are used. The boards are laid as tightly as possible to each other. If gaps remain, fill them with foam sealant.

Next, corner profiles are attached to the suspensions, then all the other frame elements. As a result, a vertically and horizontally flat plane should be formed.

Siding installation

When starting the installation of siding, it is imperative to follow the instructions. They start with the installation of the starting guide strips, then the corner profiles, after which they frame the window and door openings. Only then are the wall panels mounted. The procedure is started from the corner of the house.

- Install the bottom panel with the side edge in the corner element, and with the bottom - in the starting bar.

- The installed panel is checked for horizontalness and fixed with self-tapping screws to the frame elements.

- All other panels are installed in the same way.

- Every third row is checked for horizontalness.

The elements of the pediment are mounted in the same way.