The choice of materials for the decoration of the facade is varied: siding, SIP panels, tiles. However, the traditional option is to clad the house with bricks. The work can be done with your own hands, you first need to learn how to choose and lay the material.

Criteria for choosing a brick for cladding a house

Material selection options:

- the shape of the elements should be strictly rectangular so that the masonry is as even as possible without crooked seams;

- the integrity of the bricks: they should not contain cracks, into which liquid can enter and lead to the destruction of the masonry from the inside;

- size of elements: it is better to use narrow options that are used strictly for cladding buildings;

- you need to buy material from one batch, since a product from another may differ in shade;

- when choosing a ceramic finish, it should be borne in mind that it should not contain limestone (if water gets in, it will break down faster);

- the strength of the brick: you can check this property by hitting the product with a hammer (pieces may break off from it, but the element itself will remain intact);

- color.

Before purchasing bricks for cladding a house, you need to calculate their number. Since the elements will have to be cut, it is better to buy 10% more material.

Brick type:

- Ceramic. It is made by plastic molding and annealing. The raw material is different types of clay, which determines the load on the supporting structures. The material is matte or glossy. To reduce the mass of finishing, hollow bricks are used. There is a possibility of textured surface finishing of elements that imitate stone. The bricks can be glazed.

- Silicate. The advantage of this finish is the variety of colors. It is rarely used, since the elements are destroyed by the action of water. In addition, foundation reinforcement is required for the installation of the structure. Silicate products are cheap, but in terms of technical characteristics they are inferior to other varieties.

- Clinker. Ceramic material with improved technical characteristics. Elements formed from clay of special grades are fired at a temperature of 1200 ° C. This finish is resistant to increased loads, has a low level of moisture absorption, good frost resistance. This material is suitable for finishing window and door openings.

- Hyper-pressed. In this case, no clay is used. The material contains cement, lime, pigments. A feature of the products is a textured chip, high thermal conductivity. There is no firing here. The brick is made by pressing, it has an ideal geometric shape. It is used in individual projects.

The choice also depends on the operating conditions of the cladding, the financial capacity of the owner.

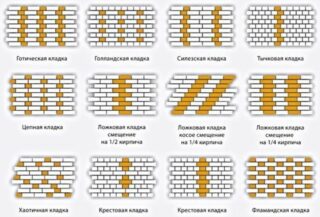

Bricklaying methods

Before you impose decorative bricks on the house, you need to choose a masonry method. Some options involve the use of several materials of different colors. However, they are difficult to perform and require some skill. The most common are the following masonry methods:

- Blocky. In this case, there is an alternation of rows with a short outer part of the element and a long one. The joints are vertical.

- Track. This is a common type of styling. It is characterized by the installation of bricks only with the long outer side. Each next row is shifted to the side by half of the element.

- Cross. In the first row, the products are laid with a long front surface, and in the second - with a short part.

- Tychkovy. Bricks are mounted with an exceptionally short part outward with a shift by half of the element of the previous row.

- Spoon. The products are fixed with a long surface outward, while an offset of a quarter of a brick is observed.

- Chaotic. Here the arrangement of the long and short sides is asymmetrical.

If the block offset option was selected, the material consumption will increase.

Cladding technology

Before laying around a house, you need to collect tools:

- a spatula for applying a solution;

- trowel (with its help align the joints and fill them with mortar);

- jointing (convex tool for smoothing and shaping vertical seams);

- pickaxe for processing material;

- plumb line, square;

- building level;

- roulette.

To keep the rows even, you can stretch a cord between the two corners of the wall. The technology for installing decorative bricks outside the building has the following features:

- Preparation. Walls must be dry, clean and repaired. If necessary, the foundation is strengthened.

- The covering of the walls begins from the upper edge of the basement, having previously leveled the surface. First, the bricks are laid without mortar, placing them in the correct order. After that, fix it with a cement mixture. The first row is laid around the entire perimeter of the building.

- First, the corners are formed, between which the cord is pulled, checking the correct installation. Vertical level adjustment is carried out using a plumb line. Next, the rows are mounted between the formed corners.

- The row under the eaves is not mounted so as not to impair ventilation.

- The openings of doors and windows are laid out in a layer of one brick.

For the preparation of the solution, cement is used without additives. Do not knead in large portions. The vertical and horizontal level of the masonry is periodically checked. Every 13 rows, using fiberglass rods, the cladding is attached to the base.

The thickness of the seam usually does not exceed 1.5 cm. After installing the brick, the finished wall is treated with a solution of perchloric acid, excess mortar and dust are removed. It is better to lay 6 rows of bricks at a time, after which the mortar should be allowed to seize.

Facing a wooden house

To sheathe a house from a bar, you need to build a finishing foundation for facing or strengthen the old one. Since insulation is placed between the base and the facing layer, it is better to use mineral wool for wood. A vapor-permeable windproof membrane is mounted on top of it.

So that the wood does not rot and rot, the vapor permeability of the wall cake materials must increase from the inside out. A ventilation gap of 4 cm is left between the insulation and the wood.It starts from the base and ends at the top of the structure. They also make airflows in the bottom row of the masonry.

Before finishing the facade, the wooden base is treated with antiseptic impregnation and fire retardant. For fixing mineral wool, a crate is made. To tie the cladding and the base, use a masonry mesh, tin strips or wire 3 mm thick. For every 1 sq.m. 5-6 connections are required.

The masonry must be reinforced. For this, steel rods or mesh are placed in the horizontal joints every 4 rows. This does not change the thickness of the seams.

Facing a brick house

Working with identical materials is not difficult. For wall insulation, you can use penoplex, which does not require additional organization of the ventilation gap. Fiberglass or flexible metal ties are used to attach the cladding to a brick wall.The pin is fixed with one end in the mounting horizontal seam of the base, with the other in the facing masonry. Approximately 4 ties are required per square meter.

Aerated concrete house cladding

For the manufacture of a facade of a house from facing bricks, the compatibility and technical characteristics of the materials must be taken into account. If the structure is built of aerated concrete, it must be borne in mind that the vapor permeability of the bearing walls is higher than that of bricks. To ensure an optimal microclimate, a ventilation gap is required. Its size is 6-15 cm.

For fixing to the base, screw fasteners or stainless steel nails, the length of which is 12 cm, are used. Perforated galvanized strips are allowed.

It is forbidden to put ties in the seams of the main wall. They are nailed to the surface of aerated concrete blocks.

Pros and cons of brick for house cladding

Before revealing a house with bricks, you need to consider the pros and cons of such a finish. The benefits include:

- wide color palette of material;

- the ability to choose the type of finishing material that is most suitable for quality and cost;

- low degree of water absorption, resistance of the finish to temperature extremes;

- finishing material provides good sound insulation;

- the service life of the cladding is 20 years.

The facade has some disadvantages:

- the mass is significant, strengthening of the building foundation is often required;

- to fix the bricks together, sometimes you need to select a special adhesive solution;

- work is difficult to do on cracked walls.

Brick is the most optimal option when compared with artificial materials, natural stone. It allows you to insulate walls, soundproof them, and improve their appearance.

When using bricks for facade decoration, you should not give preference to cheap materials. This will reduce the cost of erecting the wall, but during operation, the structure will collapse faster.

Drive those builders who build walls separately from each other. / Brick from block /. Masonry should be knitted everywhere, even in doorways, window openings