The slate covering on the house is stiff, holds the weight of the snow and does not react to the sun's rays. The slate roof is to be repaired. Reduces the sound of rain during operation. Cheap building material is used for roofing new or used sheets. Asbestos-based slate emits harmful components, therefore, it is more often used to overlap household buildings in the yard.

Slate properties and characteristics

A group of roofing materials is called a slate; they are used for roofs and as wall decoration.

Various types of slate roofs are produced:

- Natural. This category includes a coating based on natural shale by crushing rocks.

- Asbestos-cement. Sheets with the addition of asbestos fibers to the cement mixture.

- Fiber cement. There are no asbestos components in the products, they are changed with reinforcing cellulose threads and mineral plasticizers are added.

- Polymer sandy. Binder cement in this type of product is replaced with sand and polymer bonding elements.

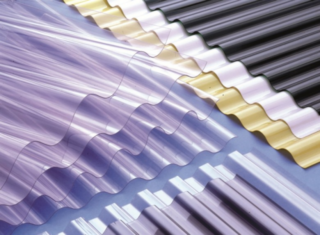

- Polycarbonate. The material is given transparency or translucency during the manufacturing process.

- Composite. Another name is keramoplast. It is a type of roofing flooring based on a mixed composition of components.

Wavy slate produced according to technical conditions in accordance with GOST 30.340 - 1995 "Asbestos-cement corrugated sheets" is used more often. The second widespread type is flat products for roof ceilings GOST 18.124 - 1995 "Asbestos-cement flat sheets".

Stiffness and strength make it possible to use slate for roofs, despite the fact that asbestos is harmful to humans. Manufacturers exchange hazardous asbestos fibers for chrysolite threads, in which the concentration of carcinogenic substances is reduced. Fine fibers are evenly distributed throughout the volume of the material and give strength similar to asbestos filler.

Production of slate sheets

First, a pulp is prepared from asbestos or chrysolite fibers by adding water and cement to the mixture. Particles of glass fiber or cellulose (depending on the variety) are introduced into the solution. The additives increase the degree of reinforcement and increase the strength.

Cellulose elements in solution bring the material closer to environmental requirements, since they replace harmful asbestos fibers in the composition. Natural components reduce the cost, reduce the concentration of expensive chrysolite threads.

The mixture is prepared in mixing tanks, the composition is taken out in special containers, which gain the volume required for the manufacture of one sheet. The ladles have holes for the liquid to drain from the mixture; after drying, the solution is fed to the molding. A vacuum pump is used to completely squeeze out the moisture, then the product is strengthened in the press compartment. The separated water is reused at the site of mixing the mixture.

The material is under the press for 30–65 seconds (depending on the technology), after obtaining the specified strength, the product is cut to size. Most manufacturers adhere to GOST standards, which regulate the composition of the mixture and set the final properties of the material.Manufacturers are allowed to develop specifications for slate production.

Forming scrap is used for reverse recycling to reduce the cost of the finished product. Products are stored in stacks on pallets, while they harden for some time. In this form, they are transported to the desired distance.

Advantages and disadvantages of a slate roof

Due to its strength, a slate roof can withstand a person and not crack if the installation instructions are correctly followed, unlike other materials, for example, roofing material. An asbestos-cement coating does not heat up in hot weather and from sunlight in comparison with metal profiled sheets (corrugated board or metal tile).

Pros of using slate roof decking:

- if installed correctly, the service life is extended in comparison with the standard times indicated by the manufacturer;

- slate belongs to the category of non-combustible coatings;

- when laying it is easily cut with a hacksaw, it is easy to fasten it, the edges are cleaned with a knife;

- does not corrode compared to metal roofing carpet;

- has dielectric characteristics.

The most unpleasant disadvantage of slate is that asbestos dust enters the respiratory tract and has a negative effect on them. The disadvantages include the fragility of the coating, vulnerability to mechanical shock and falling objects on the roof.

The material absorbs moisture, so over time, moss appears on the surface, lichen grows. The problem is solved by painting the slate area with silicone or polymer compounds. When hammering in nails, the material may crack, therefore, a hole is pre-drilled at the place where the hardware passes.

The disadvantages include the significant weight of the coating, which requires strengthening the rafter system and increasing the cross-section of the lathing elements. For example, an 8-wave sheet with a thickness of 4.9 mm has a mass of 21.6 kg.

During a fire, slate plates crack into small particles and can emit burning sparks that ignite surrounding objects.

Material life

The impeccable service of a slate roof lasts 10 years, then the material gradually deteriorates. The period is counted not from the installation time, but from the moment the sheet leaves the conveyor. But the experience of the owners shows that the operating time depends on the conditions of detention and ends with the moment when damage appears on the surface from accidental mechanical stress.

There are ways to extend the life of the material:

- correctly lay and fasten the sheets;

- paint with protective compounds;

- periodically maintain and clean surfaces.

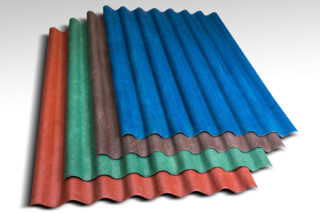

Polymeric substances on the sheet area will relieve slate from the negative effects of moisture and microcracks. Rainwater can contain aggressive acids and alkalis. With regular interaction, fibrous inclusions are washed out from the top layer of slate. The paint is applied in 2 layers with a brush, but it is better to use a spray gun.

Waterproof impregnations provide quick drainage of liquid and do not retain dust on the area. The sheet is dried, primed and painted, and the underside of the slate panel is also treated to reduce the harmful effects of asbestos.

They use TsPHV, PVC paints, protection is done at temperatures from -5 to + 4 ° C, having previously treated the surface with a perchlorovinyl primer. The intermediate layer dries up in 3-4 hours. In addition to protection, the composition on the surface improves the aesthetic appearance of the structure. Pay attention to the correct calculation of the lathing and the laying of slate panels.

The main factor of reliability and long service life is the quality of the material. The market offers many options from China, but it is better to use products from domestic manufacturers that are certified and guarantee the declared characteristics.

Calculation of the amount of material

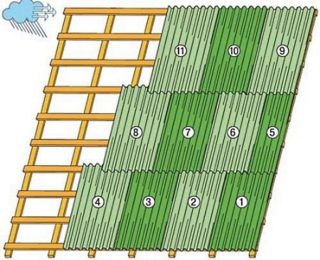

Before digging the roof with slate, you need to calculate the number of sheets. To do this, measure the length of the slope along the bottom of the overhang, divide by the width of the panel and multiply by a factor of 1.1, which takes into account the overlap of the material by 1 wave during installation. The result means the number of sheets in the bottom row.

To count the number of rows, the length of the slope (from the eaves to the ridge) is divided by the length of the slate profile, the result is multiplied by 1.13 to take into account the overlap in length. The number of sheets in a row and the number of tiers are multiplied and the required volume of material in pieces is determined. 2-3 profiles are purchased in reserve in case of a fight or cracking. If such troubles do not happen, the extra sheets will remain and it will be possible to repair the slate roof with your own hands.

Dimensions of profile products for calculation:

- 5 waves - length 1750 mm, sheet width 980 mm, panel thickness 5.8 mm;

- 6 waves - 1750 mm, 1125 mm, 6.0–7.5 mm, respectively;

- 7 waves - 1750 mm, 980 mm, 5.2-5.8 mm;

- 8 waves - 1750 mm, 1130 mm, 5.2-5.8 mm;

- roofing sheets made of flat slate have dimensions of 1500 x 2000 mm; 1500 x 3000 mm, 1500 x 1000 mm, 1130 x 1750 mm.

Slate panels must be laid on the crate with an overlap, therefore, the useful squaring of the product is reduced. The odds take into account the change and the user gets the correct count. The size of the transverse overlap is influenced by the angle of the slope. With a slight slope of 12-15 °, it is recommended to overlap with the next sheet not one, but two corrugations.

Preparatory stage of installation

Slate sheets are painted with protective compounds before being installed in the installation position. It can be processed at a height, but the quality of the layer decreases, since the bottom coating is obtained at intervals. Inspect the products in order to put the sheets on the roof without cracks or chips.

Beams are laid on the walls, the Mauerlat is mounted, then the rafters are installed. The ends of the elements are cut into the support Mauerlat. Wooden parts are wrapped with roofing material at the points of contact with brickwork or concrete to prevent moisture. A film is attached to the rafters to protect it from steam and moisture, it is laid starting from the top of the roof. The overlap is made towards the bottom to a depth of 15–20 cm so that water does not get into the gaps between the edges of the membrane.

Before covering the roof, you need to install a batten of 50 x 50 mm bars. At this time, the support hooks for the gutter are attached and the beginning of the eaves overhang is determined. If the roof is insulated, a layer of material is placed to protect it from the cold. In this case, an additional counter grill is required. The result is a ventilated space for the passage of air.

Under the slate, a crate is made of separate slats, a solid base is not used, since the material has sufficient rigidity and cannot sag. Wooden bars are fixed to the rafters with screws or nails.

It is forbidden to dock the slats by weight, they are connected on the rafters, the seams are staggered.

The crate is reinforced around the roof outlets of pipes, collectors, ventilation outlets. Double bars are placed on the ridge, valleys, gutters.

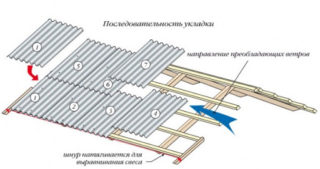

DIY slate roof installation technology

Sequence of work:

- calculation of the place of laying;

- the beginning of the installation of the first row;

- continuation of the set of sheets in height;

- arrangement of the ridge area;

- installation of steel lining, parapets;

- installation of snow holders.

The first row is aligned horizontally, for this, a cord is placed at the bottom of the eaves. Each panel is fixed at 9 points, there are three of them on the line. The extreme one is no closer than the second wave is from the edge of the sheet. Slate nails are used, which are equipped with plastic or aluminum caps.Fasteners are driven into the crest of the wave so that the panel is firmly pressed against the sheathing.

At the top convergence of the slopes (ridge area), the edges of the sheets are cut along the stretched fishing line. Do the same with inclined ridge sections. One side of the forceps area is trimmed along the lace, and the other is marked with a pencil.

In valleys, the joint is made as follows:

- an overlap line is drawn on the extreme panel;

- a gap is measured from it to the center and the upper section;

- the result obtained is marked on the slate, then cut diagonally with an indent of 2-3 cm.

The second row is placed starting from half of the sheet. Further, the installation can be carried out immediately in 2 rows, since the specified offset will be obtained automatically.

If you choose the option of installing panels without displacement, there will be 4 slate edges at the joints. The corners of the two need to be cut by 130-135 mm to reduce the thickness of the joint.

Slate roof maintenance and repair

Inspection of the slate coating is carried out in spring and autumn in order to identify damage in time. They clean the surface with improvised means, for example, with a broom, but it is better to use an electric pump. In winter, it is better not to get rid of ice and snow, but to place holders of the snow mass and wait for an independent gradual convergence.

Slate roof repair methods:

- Using cement-based mortar. The binder and sand are taken at a concentration of 1: 2. Sometimes the mass is replaced with a special cement-based roofing glue.

- Using butyl rubber tape for sealing. Such a strip is placed not only during repairs, but also at the points of joining the roofing to the ledges. Before using the nonwoven tape, degrease the area with a solvent.

- With bituminous mastic. Do a cold or hot coating of the problem area. In frost, oil waste is added to the molten resin to prevent cracking.

- Covering with epoxy, silicone or polyurethane foam. The edges are cleaned from irregularities, filled with polyurethane foam, then wait for drying. The expanded excess is cut off, a sealant is applied.

Whichever method is chosen, it is better to make repairs right away and not wait for further destruction of the problem area.