The cage prevents skewing of the window frame installed in a wall made of timber or sawn timber. As a result, the glass remains intact, and the surface of the adjacent slopes and the binding itself are not deformed. Shedding in a wooden house is carried out in the form of a box made of thick boards, a bar, which is mounted in the opening before installing the window block. The design has an original fastening, which does not provide for rigid fixation to the wall ends.

Varieties of casing for windows

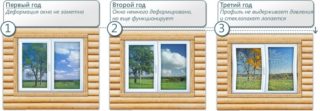

A wooden house shrinks over time or swells when humidity rises. Changing the geometry of the walls leads to the transformation of the window frames. Shrinkage usually lasts a year, but in some cases stretches over 3 seasons. To weaken the effect of subsidence, a strapping box is placed in the window opening.

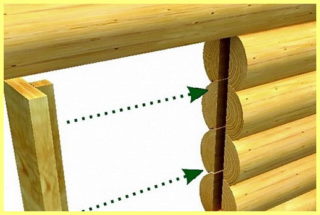

There are three (top and sides) or four (top, bottom, sides) elements in the design. Accordingly, the window is made open or closed around the perimeter. On the sides, there is a connection with the walls in the form of a thorn-groove. Such a joint allows the wall to change dimensions independently of the window, since the casing slides along the groove and does not deform.

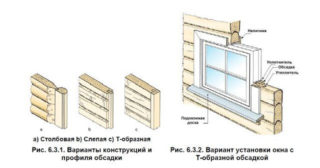

There are types of framing the opening in the wall:

- T-shaped box. The cross-section of the vertical elements looks like the letter T, hence the name. The inner plane remains flat, and the spike is made from the outside. A gasket is placed to seal. A groove is cut out at the end of the wall for placing the casing spike there. The upper and lower boards have a similar structure.

- U-shaped casing. It is a construction of the opposite type, when the spike is made on the wall end, and the groove is cut out on the window frames in a wooden house. The vertical posts are put on with a recess on the ledge of the wall cut. The lower and upper bars are set as well. The variant is used more often than the T-shaped one.

Distinguish between rough casing, when work is planned in the house for further interior decoration. The accessory box is made from inexpensive species such as pine or spruce. The finishing casing is installed in buildings where there is already a finishing of the premises and wood of expensive varieties is used.

The Euro-fence is made of individual pine planks, firmly glued on a fixing compound. There is a version of the power casing, which is thicker. Due to its strength, it is used for large windows and other extraordinary cases. Such structures are also made in an adhesive manner.

The Eurosad and the power version are more expensive compared to other models. Casing for arched windows can be ordered in carpentry workshops according to an individual project. Combined casing is made so that resinous wood is in contact with the wall, and the front surface is made of beech, oak, birch.

Installation rules

The window of the log house must be installed so that it is mobile and can freely slide along the longitudinal groove or spike of the wall. You can make a movable connection if during installation you do not use hardware to connect the structure to the end of the vertical fence of the house.

A gap of up to 12 cm is left between the upper beam, which compensates for the shrinkage of the log building. Subsequently, the gap is caulked with tow, jute, insulated and closed from the outside of the house with platbands. For sealing the cracks, polyurethane foam is not used, which can make the end-end and the window joint permanently connected. Over time, the gap will gradually decrease, and solid, fixed insulation should not interfere with this process.

First, the lower bar is mounted, then the side elements are installed, the installation is completed with the upper board. All parts are treated with antiseptic preparations to prolong the service life and prevent destruction from fungus and rot.

The house sinks due to improper drying and aging of wood, climatic conditions and unreliable foundations. The casing itself must be made of dry wood in order to avoid shrinkage during operation. Natural material can change the moisture content, so the risks are minimized by placing a box made of material artificially dried in chambers.

The casing and windows are mounted in a house that stood for a year after construction with a roof so that the wood deforms and takes on constant dimensions and shape. The rules for installing the box are regulated in the standards GOST 30.971-2012, which contains technical instructions for the implementation of assembly seams and knots when joining windows with walls.

Consequences of technology disruption

Failure to comply with the technique of installing and securing the casing or installing windows without the use of a window leads to unpleasant consequences.

The natural cause (shrinkage) leads to the following changes:

- the appearance of gaps between the frame and the logs of the walls, the presence of drafts;

- curvature of the frame at the junction of the binding or deformation of the casing itself;

- cracking of a double-glazed window, glass falling out;

- failure of window devices for opening the sash, mismatch of the latches with the strike plates.

Artificial causes of trouble lie in the incorrect assembly of the strapping box or its fixation to the wall with self-tapping screws, bolts. Often the structure is made without grooves or protrusions and smooth boards are placed. With such an attitude, the box can move out of the opening, since no obstacles prevent it from doing so.

Many companies offer plastic casing or other materials. Dissimilar materials in the construction of a wooden house behave differently, since they have different properties. They have different linear expansion coefficients when heated, humidified. It is better to use natural or glued wood when installing casing in a log house.

Making a window for plastic windows

A double-glazed unit in a PVC frame is a complete structure that is ready to be installed in a wall hole. The opening in this case is a strapping cage. Measure the size of the window block in width, height in two places to find out the internal dimensions of the casing and make a drawing.

Materials for making a window:

- Carriage, another name for side elements. A wooden beam is used, the thickness of which corresponds to the transverse dimension of the wall. They take the minimum dimensions of 15 x 15 cm, the maximum - 36 x 15 cm.

- The top is a part of the window that stands on top of the frame. They are made from a bar of 15 x 5 cm.

- Insulation. Mineral, stone, glass wool, natural wadding-linen or jute are used.

- Antiseptic. Purchased in the construction market for wood preservation.

The frame in the opening is bursting with wedges made of wood or plastic, you can cut them yourself or purchase them in a store. Homemade parts are impregnated with linseed oil and allowed to dry before use.

The design of the casing was invented a long time ago, so there are certain manufacturing rules:

- the window opening should be at a height of 80 cm from the floor surface inside, with this calculation, a hole is cut in the wall for fastening the casing, while taking into account the thickness of the window sill.

- insulation is laid around the entire perimeter, without exception;

- when assembling the casing box, you need to ensure that the self-tapping screws that are used to fix its elements do not enter the body of the wall;

- finishing on the outside and inside of the house begins after the installation of the window and window block is completed.

When installing the sidewalls, the verticality is controlled using a plumb line, and the horizontalness of the upper beam is checked with a building or laser level. The gaps between the window sash and the inner surface of the casing are sealed with polyurethane foam, the remains of which are cut off after a day.

List of required tools and materials

To install a jamb in a log house, you do not need a drill or a perforator, since the fastening is made in a groove-tenon. An electric drill or screwdriver will be needed to fix the sidewalls and the vertical bar to each other, for which self-tapping screws are used for wood with a protective coating against rust. A drill is needed to attach the window frame to the window or fix the plastic windows to the box of the installation plates.

Installation tools:

- Phillips and flat screwdriver;

- tape measure, pencil, square, level, plumb;

- rubber or wooden hammer;

- pliers, wood saw, knife;

- Allen wrench for tightening the bolts on the window hardware.

A groove or ridge on the communicating verticals of the jigs and walls is made using a chainsaw, a drill, and an electric jigsaw is used. You also need a grinder with a grinding wheel or a grinder.

Wedges are prepared from the materials, foam is used to seal the gap between the frame and the casing, sealing tapes are used, which have the effect of vapor permeability. You will need a tape membrane for waterproofing, fasteners for window sashes, diffuse tapes. Silicone sealant, window sill spacers and support brackets are used. For the spacer of the window frame, before foaming, take strips with a thickness of 25 x 40 mm.

Installation of a window frame and a window frame in the opening

Before installing the casing, prepare an opening cut in the wall from a bar. Check the verticality, horizontality, turn of the side surfaces.

Further procedure:

- make a cut along the perimeter of the window and choose the thickness for the thorn at the ends of the wooden wall;

- parts are impregnated with anti-feather and antiseptic;

- the lower bar is placed first so that it determines the position of the side elements and prevents them from moving;

- a heater is preliminarily placed under the lower bar;

- install the side parts (carriage), put a soft insulation or sealing tapes into the thorn-groove connection, lay waterproofing;

- the last one is to mount the upper element, on top of it, a mezhventsovy sealant is placed in the gap.

To install the frame, the window is disassembled, the double-glazed windows are taken out in order to observe the installation technology and to avoid the frame protruding from the foam. The frame is exposed in the window opening with the help of holders and installation parts, wedges are used. Spacers are placed in the middle, above, and below, and the upper and lower parts of the frame are fixed with self-tapping screws at once.

After foaming the mounting gaps, leave the foam to dry, then remove the excess. The window sill is cut out along the casing opening, fixed to the substitution part. A small opening is sealed with a sealant, foam, for a large one, a lumber is required.

The window sill is placed with slopes inside the room (5 °). Outside, the ebb is strengthened, lugs are installed to drain internal condensate from the frame. The elements are attached to the casing, but not to the walls. Move on to finishing the slopes.

Advantages and disadvantages of casing in a wooden house

The correct strapping box additionally insulates the structure, protects the interior from noise, hum, and harsh sounds. The okosyachka strengthens the wall plane, in the area of the thorn-groove connection there is no protrusion of the ends under the influence of shrinkage. The openings for the openings weaken the vertical barriers, and the cage makes them stiffer and prevents the beams from moving along the central axis. If the walls are shrinking vertically, the casing protects the frame cover from pressure from above.

The disadvantages of the U-shaped casing are that the material consumption for the box increases (it is put on the spike of the wall); a wider bar is required. The figured configuration of the frame is expensive to manufacture. But the price for its manufacture is lower than that of the T-shaped casing.

In the latter version, the spike can be formed on the frame itself from a solid solid or made overhead from a wooden profile. The disadvantage is that you need to pay attention to its fastening, so that there is no flaking and the appearance of cracks for drafts.