The frame construction method is very popular due to its simplicity, lightness and speed. However, with this technology, special attention should be paid to the design of each node or element. The warm corner of a frame house is not the result of a simple joining of two walls. In order for the node to keep warm in the house, you need to perform certain actions.

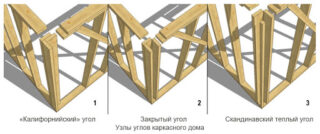

Varieties of a warm corner of a frame house

Angle is a knot obtained when joining walls. It carries a higher load than a wall. In addition, the likelihood of the appearance of cold bridges is higher here, especially with the frame construction method.

On the Russian market, a scheme is common in which the angle is formed by a bar. However, this option is bad at once for 2 reasons. Firstly, it is the coldest element in the wall, which there is no way to insulate. Secondly, there are no shelves from the inside to which the trim could be attached. In a frame building, this is difficult.

In order to prevent heat loss, several other structural schemes are used during construction.

California

An American or Californian assembly scheme can serve as a benchmark for economy with sufficient reliability and optimum durability. There are several options for such a frame. None of them use the beam as a corner post. With rare exceptions, the rest of the rack supports and strapping are made only from dry planed boards.

The California scheme involves the installation of an additional rack or piece of OSB in an already mounted corner. It is fixed on the inside and gives the corner more rigidity. It also serves as a support for the installation of the inner lining. In this case, the trim is attached to the inner part of the corner - the fasteners do not form a cold bridge with the outer part of the corner.

The California corner is insulated along with the wall.

Closed

This option also involves the use of a board. An additional rack made of wood is installed between the wall racks so that it forms a kind of shelf with the corner element. The shelf is facing outward, so it is not accessible from the inside.

During the finishing of the facade, the shelf is filled with insulation and sewn up. This design perfectly retains heat, as it is additionally insulated.

The corner post is insulated before the facade cladding.

Scandinavian

This option is used much less often, in regions with a really harsh climate. It appears more often in buildings assembled according to the Canadian scheme. In this case, the 2 corner posts are fixed so that the corner itself is facing the inside of the building, and the wall posts are adjacent to its surface. The knot is reinforced with an additional rail.

The design provides high rigidity, but at the same time eliminates the appearance of cold bridges, since the unit is inaccessible from the inside. The resulting cavity with a supporting rail is filled with insulation and sewn up with a finishing material along with the walls.

Structurally, this option is not always possible, so it cannot be used "by default".

Monolithic

An option that is not recommended for use during construction. The corner element is a square or rectangular bar. Installing it is a little easier than assembling multiple boards.But this is where all its advantages end. An additional disadvantage: even well-dried timber is more prone to cracking than a board. Therefore, over time, the risk of the formation of cold bridges is much higher here.

The main requirement for the material is low humidity, no more than 19%. For construction, only dry edged boards with a section of 50 * 150, 50 * 200 mm are taken. For the Californian node, you can take scraps of the OSB board, since here the additional rack makes the structure rigid, but does not increase the bearing capacity.

Important recommendations

In order to make a warm corner when building a frame house, you must adhere to some recommendations. Ignoring the requirements of technology or oversight in the choice of materials will negate all efforts.

- First of all, you need to abandon the classic execution of the corner - the installation of a bar. Any of the schemes, even the simplest Californian one, turns out to be more energy efficient than this solution.

- Do not use natural moisture material. When dry, the board changes size. Since the frame method provides for a rigid fastening of the elements, the finished frame or even the wall begins to "lead". Joints, especially corner joints, lose their density and cold easily penetrates into the building.

- You cannot use boards with a smaller section than indicated by GOST. In the standard American scheme, it is allowed to take material with a section of 140 * 38 or 35 mm. But at the same time, the typical installation step here is 40 cm, since the insulation plates sold in the North American market have such dimensions. In the Russian market, the standard size of polystyrene or polyurethane foam is 60 cm, which means that the frame racks have to be installed in 60 cm increments. The load increases, including on the corner element.

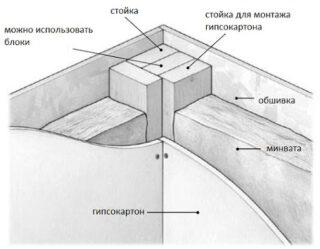

- It is forbidden to use any types of roll heat insulators for thermal insulation. They have too low a density and give too much drawdown. It is best to use basalt or mineral wool of sufficient density - 50 kg / m³ and 30 kg / m³, respectively.

The most common mistake when arranging frame corners is the use of black self-tapping screws and perforated corners. Such fasteners are cheap, fasten quickly and give the impression of a successful solution. This is not so: black self-tapping screws are designed for fastening GL, GVP and other light materials, they cannot hold the boards.

The insulation in the corner piece must be protected from steam and condensation. Since the thermal insulation is located outside and is an element of external insulation, it is recommended for these purposes to take windproof films with vapor permeability that meets the requirements of the finishing facade material. You cannot save on films.

It is not allowed to use different schemes for building corners on the same floor. Their indicators are different, a similar technique leads to distortions and damage.

During installation, any vertical posts, especially angular ones, are checked for verticality.

Required tools and materials

To build a warm frame corner, you will need the same materials and tools as for building the house itself:

- 3 or 4 boards for arranging a corner element with a cross section of at least 50 * 150 mm.

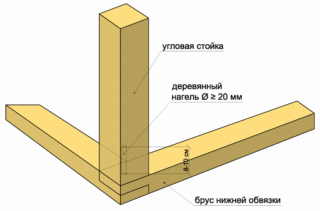

- Galvanized nails 150 mm long. Anchors and silver pins can be used, but not black.

- It is allowed to use wooden fasteners - dowels. Better to take oak, as they are much stronger. Diameter - 20 mm. For dowels, it is necessary to pre-make holes in the boards.

- Insulation - mineral or basalt wool.

Boards should be treated with fire retardants and antiseptic impregnations before use.

Installation technology

The assembly method of the subassembly is one of the elements of the initial design. This is taken into account in the calculations.

- Before installation, check the horizontalness of the lower trim bar.The elements must be held together at exactly 90 degrees. The accuracy of the angle is checked at a distance of 3 and 5 m.

- The frames of the walls are assembled, taking into account the type of corner element: angle inward, angle outward.

- The frame of one wall, assembled on the floor of the 1st floor, is installed in a corner and fixed with a jib in the desired position.

- Raise the frame of the second wall and fasten it to the lower beam perpendicular to the first nails with a length of at least 70 mm in increments of 40 cm.

- Having stepped back from the extreme rack of the first wall 10 cm, an additional rack is inserted into the formed corner and fastened so that the end of the board protrudes beyond the plane of the second wall. Thus, a shelf is formed for fixing the interior trim.

- From the inside, the resulting niche is sheathed with a vapor barrier, then the cavity is filled with insulation. This must be done. Although wood is a heat-retaining material, the "empty" corner in contact with outdoor air is not. In addition, when cracking, the cracks become cold bridges.

- After installing the entire frame of the 1st floor, the walls are sheathed with clapboard, edged board, siding.

A warm corner in a frame building is the result of a properly selected structural scheme. The standard solution - installation of a bar - does not provide this. It is necessary to mount an element of several boards and fill it with insulation.