For heating the premises and cooking food, a large number of private property owners choose brick stoves. These structures have a lot of advantages, a rather simple device, although the issue of their construction cannot be called easy. Knowing the device of a brick stove, from which it is made and instructions for laying, it is possible without much difficulty and inexpensively such a hearth that, in terms of its working and aesthetic characteristics, will not be inferior to models from professionals.

Furnace designs

Brick home stoves are attractive to users in many ways. With outward simplicity, they differ in a variety of possible modifications.

By design, structures are divided into the following categories:

- For heating. A budget suburban option, which includes a minimum of options - a body, a firebox and a chimney. A small economy class miner can effectively heat an apartment or a summer house with an area of up to 20 m². It is made in the form of a cube or parallelepiped with walls half a brick thick. The design is simple enough to handle making it yourself.

- With a hob. An excellent option for buildings that are operated in the warm season. Can be installed in kitchens and living rooms. The stove is supplemented, if necessary, with an oven and a hot water tank.

- Combined models. Designed for heating, cooking and as a dryer for clothes and shoes. The structure is large, massive and rather complex. As a rule, it requires equipping with its own foundation. Sometimes the arrangement of the lounger is carried out, both top and floor type.

- Multifunctional. A very large stove complex, which is installed in separate rooms of a village building or on the street, in gazebos of a closed type. The product has several sections for heating, stewing, smoking, frying and drying. There are several fireboxes, it is planned to install cabinets, tables, shelves. The two-bell project has several arches and chimneys.

When choosing a brick oven device, you need to think ahead, not focusing on savings. It is better to stretch the process of making the hearth over time, but to make an effective structure right away, so that later you do not have to deal with complex re-laying.

Options for installing the stove in the house

A stone hearth is not only a multifunctional heating device with many options, but also a potential source of danger for the inhabitants of the house. The classic Russian stove runs on wood, and this is the risk of fire and carbon monoxide poisoning. In addition, one should not forget about the convenience of using the structure.

When choosing a place for a small wood-burning stove, you should adhere to these time-tested recommendations:

- By placing the stove in the middle of a large room, you can effectively divide it into zones of different functionality. As an example - kitchen, bedroom, living room, dining room. Over time, you can put a partition, making several small and cozy rooms.

- You should not put the hearth close to the outer wall, especially the northern one. So all the energy will go into it, and the product will work almost idle. If, nevertheless, such a decision is made, thermal insulation should be done.

- Arrangement of a reliable foundation. A structure, even the smallest, weighs from a ton or more.It must have its own foundation, independent of the main structure.

We should not forget about the aesthetic component. The design should please the eyes of everyone at home, creating a feeling of comfort and coziness.

Pros and cons of brick ovens

If you build a stove yourself, you can save a considerable amount on the services of a stove-maker, which may even exceed the cost of the material.

The presence of a brick hearth in the house gives significant advantages:

- Presentable appearance, creating a feeling of comfort and coziness.

- Long service life. The product is not subject to corrosion, tolerates high and low temperatures without problems.

- The speed of construction. Do-it-yourself bricklaying of a brick oven - the simplest option takes only a few hours, even taking into account the preparatory measures.

- High efficiency. With a correctly chosen block stacking scheme, it is quite possible to keep within one day. Fuel is consumed less than a potbelly stove, and heat transfer is higher.

- Fuel versatility. You can use cones, briquettes, logs, stems, straw, old furniture, and plastic.

Disadvantages of the design:

- Quite large in size. There is no need to talk about compactness.

- You need to build a hearth on a separate foundation. It is easy during the construction phase of a building, but extremely difficult during its operation.

- To put together a high-quality and beautiful stove, you need a very competent ordering drawing, skills in laying bricks and preparing mortar.

Arranging a home stove is a step-by-step process, each step must be thought out to the smallest detail and performed in strict accordance with the technology.

How to choose a brick for a stove

To make a high-quality oven with your own hands, you need to choose a special refractory brick made from special types of clay.

- Alumina (fireclay). The basis is the “Shamot” variety. In the process of firing, the raw material is compacted, moisture is evaporated from it, and the surface is melted. The blocks can withstand temperatures of 2000 degrees, which makes them an irreplaceable furnace cover.

- Red ceramic. Subdivided into standard and refractory. Withstands heat up to 1750 degrees. It is used to form the body of the hearth, lounger and chimney.

Quality blocks have high thermal conductivity, frost resistance and low voidness. Detailed material, when struck with a hammer, emits a dull sound, and when splitting, it has a different color in volume, which indicates a low quality of raw materials or a violation of production technology.

Selection of sand and mortar

For masonry, a special solution is used that is resistant to extreme heat, temperature extremes, moisture and the resulting creosote condensate and soot combining.

For work, a solution is used, consisting of the following components:

- River sand. The substance is first sieved and then washed and calcined. The ratio is 70%.

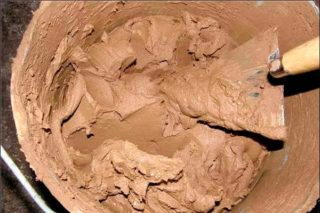

- Fireclay clay. The material is soaked for several days, mixed and used in a volume of 30%.

If, during the operation of the hearth, it becomes necessary to shift several rows or add new options to the object, a solution of a similar composition should be used.

Place to install the oven

With regard to the choice of a site for a stationary hearth, only fire safety rules apply. Everything else - size, color, design, decoration - is determined by the owners based on the conditions, their own tastes and priorities.

If the room is large, it makes sense to arrange a hearth in the middle. This will provide the most efficient heating, free access to any part of the structure. The disadvantage of this solution is that the chimney will have to be led out through the ceiling and roof.

For medium to small sized rooms, it is advisable to install a fireplace in a corner or against a wall. You can improve the level of heating by installing a screen, which is made of a heat-insulated sheet of metal.

Masonry process

Step-by-step procedure for arranging a brick oven:

- Foundation making. The simplest and most reliable option is pipe or pile. The supports are deepened below the freezing point of the soil; a reinforced concrete slab is installed on the tops.

- Dry styling. The stones are laid out on the base, taking into account the seams and adjusted to size. This technique allows editing continuously, without wasting time on trimming.

- Derivation of the first level. It is made with a solid height of 3 tiers. First, the waterproofing is laid, and already on it a layer of mortar with a thickness of 5 mm.

- Formation of walls with holes for a blower, a firebox and channels for a sunbed, if provided for by the project. The doors are attached directly to the wire, which is passed through 3 bricks on the sides with a drop of 1 level.

- Executing the top bar. It is made of brick or the opening above the firebox is closed with a steel plate.

- Chimney construction. At the same time, a hot water boiler or heating circuit is embedded in it.

After the completion of the masonry, the oven should stand for 7-10 days, after which it is heated and finished.

Even at the design stage, you need to make the best decision regarding the type, size and location of the furnace. There are difficulties with the choice of real and high-quality bricks, as the market is flooded with fakes. If the laying of the hearth does not cause any special problems, then the arrangement of the foundation and the passage of the chimney through the roof are serious questions and require a thoughtful approach.