Roofing is a responsible procedure that requires strict adherence to technology. The microclimate inside the premises, as well as the quality and duration of operation of the structure and the building as a whole, depends on the correctness of its implementation. Roof vapor barrier is one of the most important stages of work. Thanks to her, the elements of the roof are protected from the negative effects of moisture.

The need for a vapor barrier for the roof

The roof is affected by external and internal aggressive factors, so it requires reliable protection. Steam accumulates on structures in the form of condensation, and gradually leads to rotting of wooden elements. Another feature is the ability to penetrate into any materials. In winter, steam settles in the insulation, and under the influence of negative temperatures freezes and destroys the insulator from the inside.

Roof vapor barrier is used if the structure is simultaneously exposed to cold and warm air. Due to the temperature difference, condensation forms in the insulation, which degrades the properties of the material. Protection is mandatory when erecting attics and attics that will not be heated.

Protection is needed in rooms in which the heating system does not work regularly: country houses. Be sure to use a vapor barrier for a flat roof. Multilayer structures need protection, as well as ceilings, for the insulation of which fibrous or bulk materials were used.

Material selection criteria

Roof steam and moisture insulation is selected taking into account the type of structure, building operating conditions and other factors. The material must have the following qualities:

- Waterproof. The material must protect against steam and direct contact of structural elements with liquid.

- Duration of operation. In the future, it will not be possible to replace the vapor barrier layer without disassembling the roof, so it is better to immediately choose products that last at least 15-20 years. Manufacturers who guarantee the quality of their products indicate this information on the packaging.

- Strength. An insulator that is resistant to mechanical damage can well protect the structure. It can withstand heavy loads and does not break during installation.

- Refractoriness.

- Installation method. The insulating material can have an adhesive surface or be fixed with a construction stapler.

- Resistant to sunlight. This requirement is mandatory if the roofing material is damaged.

- Water vapor permeability. The rate of equalization of steam pressure between adjacent elements of the under-roof space depends on its level. It is determined by the structure of the material used, its thickness. The higher the value, the lower the likelihood of moisture accumulation inside the roofing cake.

- Ecological cleanliness.

The choice of a vapor barrier depends on the climatic conditions of the region. Average annual temperatures are required during the winter and summer seasons. The purchase of an insulator is influenced by the nature of the use of the space under the roof, as well as the type of material used for the roof.

Materials used

Different types of materials are used for the vapor barrier of the roof: films, membranes.

Polyethylene

Plastic wrap is the most common type of insulation. It is versatile, easy to use, and effective. The material simultaneously protects the roof from the effects of steam and moisture. To improve the properties, the film is reinforced with fiberglass. This procedure increases the mechanical strength of the insulation.

Roll polyethylene is perforated and integral. The first option is used for all types of roofs. This material can be of several types: with a reinforced layer of fabric (polymer) or with a reflective aluminum coating.

Polypropylene

A feature of polypropylene insulators is the presence of a viscose-cellulose layer, which prevents the appearance of condensation. It simply absorbs moisture on its surface. At the same time, it does not reach the insulation, but evaporates. The level of vapor permeability of such a film is 0.4 g / m2. If the roof is flat, the PP sheeting can be used as a waterproofing barrier.

Membrane

There are several types of membranes:

- Low diffusion. The material is only suitable for dry rooms and mild environmental conditions.

- Medium diffusion. Used in temperate climates and moderate use.

- High diffusion. This material is suitable for harsh climates.

The membrane consists of 2 or 3 layers. The advantage of the second option is the presence of an intermediate reinforcing layer that increases the strength of the material. It does not affect gas exchange in any way. There is a layer of air between the outer layers.

The difference between waterproofing and vapor barrier

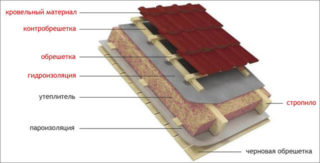

The vapor barrier must be installed on the inside of the structure. The material must protect the structure from the attic side from moisture rising from the room. Even with well-organized ventilation, steam is present in the rooms. Many owners use modern irons and air humidifiers. Excess liquid appears as a result of watering indoor plants. To prevent this moisture from penetrating into the insulation, deteriorating its technical characteristics, installation of a roofing vapor barrier is required.

The waterproofing material is designed to protect the roof structure from the influence of external moisture. Metal tiles, slate do not allow snow or rain to fall directly on the rafter system. However, in the presence of fog, moisture still penetrates under the roof. Waterproofing prevents it from accumulating in the insulation layer.

The main types of vapor barrier

All materials can be divided into 2 large groups: roll and sheet.

Roll-up vapor barriers

- Premium. It has the highest quality that can be achieved thanks to the use of modern technologies and equipment. Polymers and bitumen are used for production. The use of products of this type is allowed in private construction and in the industrial sector. The material is able to withstand harsh operating conditions.

- Business Class. The product is characterized by reliability, but in terms of durability it is inferior to the first type. Such a vapor barrier film for the roof is distinguished by flexibility, high density, and endurance.

- Standard. Such products are not allowed to be used in all climatic zones. In a harsh climate, they will not perform their assigned functions. You should not use this class of film on roofs with a steep slope.

- Economy. This is a budget insulation option, so it is inexpensive. However, its strength is not very high.

Sheet wind and vapor insulation for the roof is used if a significant mechanical load is exerted on the roof. When installing such a product, you need to glue the seams between the canvases with high quality.In terms of technical characteristics, sheet insulation does not differ from roll insulation.

- Yutafol. Several types of material are produced under this brand. The most durable is the three-layer refractory version. It acquires this quality due to the presence of a special reagent in the product. There is a reinforcing layer inside, the surface is laminated on both sides. A four-layer aluminum reflective film is available. The density of the material is 170 g / m². Such insulators can be chosen for all types of roofs, they are resistant to the development of fungus, and provide good ventilation of the under-roof space. Laying the film is not difficult. When microcracks are obtained, the quality of the material deteriorates.

- TechnoNIKOL. The material has a three-layer structure, therefore it is resistant to moisture and durable. Laying the film is allowed on a rough surface. The manufacturer produces an insulator for different types of roofs: for pitched - diffusion version, for flat - perforated or integral. The material can be used in a wide range of temperatures: from +100 to -60 degrees. It is environmentally friendly. A two-layer product is capable of replacing roofing material for a short time, since it has a high level of strength.

- Izospan. The product is characterized by increased water-repellency. Mold does not form on it. The material is durable, easy to install, environmentally friendly. The operating temperature ranges from -60 to +80 degrees. Manufacturers claim a service life of 50 years. Depending on the brand of the film, its density is 70-190 g / m³. However, the material does not have very high resistance to ignition, and with some varieties, you need to be careful in installation so as not to damage it.

- Ecolife. Due to its two-layer structure, the film can be simultaneously used as a vapor and waterproofing barrier. The material is resistant to direct sunlight for 3-4 months. The water resistance is over 1000 mm. water Art. The presence of polymers in the composition of the film makes it easy to use, environmentally friendly, and effective for a long time. The material has high tensile strength, is inert to chemical and biological factors.

The installation of a vapor barrier is a mandatory stage in arranging the roof, contributing to the long-term operation of the under-roof space and the roof itself.

DIY installation features

There are 2 ways of attaching the film: to the rafters on the inside of the heat insulator, as well as to the rough finish of the attic or attic.

Galvanized nails or a construction stapler with staples are used as fasteners. All points at which the vapor barrier broke through must be well sealed. The canvases are laid horizontally from bottom to top with an overlap, which is 15 cm. To prevent the joints from passing moisture, they are glued with construction tape or tape that comes with the material. Seals well joints with adjacent surfaces.

If a film with a foil layer is used, it is directed inside the room. Installation technology has some nuances:

- If the vertical laying direction was used, the film is laid from the top of the structure.

- Minimum overlap of at least 10 cm.

- The sealing tape is 10 cm wide.

- It is not recommended to use scotch tape based on polyurethane or butyl rubber, as it loses its tack over time and leaves the base.

- When using double-sided tape, it is first fixed inside the overlap on the lower web.

- If the roof slope exceeds 30 degrees, the film is additionally fixed with clamping strips.

- When finishing window openings, an overlap is provided, the width of which is 2-3 cm (in the form of folds).

- The ventilation pipes are wrapped with a film, which is fixed with construction tape.

- The installed insulation around the roof window is protected by an apron.

- When using foil protection, adhesive tape with aluminum spraying is used to connect the canvases.

It is forbidden to lay the vapor barrier so that it envelops the elements of the rafter system, since in the event of condensation, the tree will begin to rot.

So it is then possible to lay a vapor-barrier film both from the outside and from Nutri. Why hydro, vapor barrier is it better, or do I not understand correctly?