Buildings made of logs and beams are characterized by environmental friendliness, excellent thermal insulation properties and a comfortable microclimate. However, natural material absorbs moisture well and is prone to rotting at its constant high level. The main risk area in this regard is the first floor level, which is the boardwalk. The coating is in contact with the subfloor, which causes temperature fluctuations, dampness and condensation. In order to prevent the wood from getting wet and the development of mold in it, the vapor barrier of the floor in a wooden house is carried out. It is not particularly difficult, but is characterized by a number of nuances regarding the choice of materials and the rules for their installation.

What is a vapor barrier for a floor

One of the reasons given priority in favor of wooden buildings is its ventilation properties. The material is able to take excess moisture from the air inside and let it out. This ensures that a constant level of humidity and a healthy atmosphere is maintained in the house. Since most of the moisture potentially enters the building from the soil beneath it, the main efforts to protect the structure are focused on this structure.

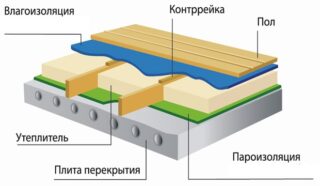

Vapor barrier is a layer whose task is to cut off the fumes coming from the ground from the floorboards and insulation, keep them dry, and ensure constant air circulation. To achieve this, materials are used that trap water vapor on one side, but freely pass it on the other. In fact, it is a canvas containing a huge number of microscopic valves that act as a dry-type drainage system. There are enough of such products on sale, but not all of them are suitable for arranging high-quality vapor barrier.

The need for vapor barrier for the floor in a wooden house

For a wooden house to be beautiful, cozy and comfortable, it is necessary to take care of each of its elements even at the design stage. It will be very difficult or simply impossible to add the missing details later, since destructive processes can become irreversible. This fully applies to vapor barrier. This part is small, inexpensive and does not require a lot of installation time. The consequences of ignoring it can be simply disastrous for both the building and the people living in it.

This is explained by the following factors:

- A steam coming from the ground needs a way out. If it settles on the logs, they will rot. Accumulation on waterproofing is also not good. This is a wet basement, soil, fungus and unpleasant odors.

- There is an excess of moisture in the room from time to time. This happens during rainy weather, washing, cooking, cleaning floors and walls. Water accumulates under the floorboards and penetrates into the insulation. Membrane sheets provide steam escape from the inside, acting as a passive floor dehumidifier.

A vapor barrier for a floor in a wooden house is a vital structure that directly affects the health of people and the functionality of the building.

Varieties of vapor barrier

The trade network offers a wide range of materials that are presented as vapor barrier. Each of them has a certain list of performance characteristics, in one way or another corresponding to the intended use of the coating.

When choosing a canvas, you should pay attention to its compliance with the following requirements:

- breathability;

- strength;

- durability;

- resistance to dampness;

- immunity to fungus and decay.

Manufacturers are announcing these types of products as a possible option for vapor barrier flooring:

- Polyethylene film. A material with a wide range of applications, used for decades in internal and external work. Differs in absolute impermeability to air and moisture. It is an excellent waterproofing layer for water, but it is categorically unsuitable for the floor, as it promotes the formation of dampness. In addition, cellophane breaks easily, at low temperatures it loses its elasticity and collapses. Experts do not recommend polyethylene for use.

- Polypropylene film. A modern coating designed specifically for interior work in wooden buildings. It has a multi-layer structure containing an anti-condensation layer of cellulose and viscose, which absorbs and retains significant amounts of moisture. Due to its high hygroscopicity, condensation does not create drops, and the absorbed moisture gradually dries out. When buying, you should abandon models that do not have an absorbent layer, since they form drops that are absorbed into the wood.

- Diffuse membranes. An innovative material that ensures complete tightness while simultaneously removing moisture from under the floor space. The fabric is made of non-woven artificial fabric, it is distinguished by its strength, durability, resistance to temperature extremes. The fabric can consist of several layers, where their number directly affects the effectiveness of dehumidification.

When choosing products for styling, it is recommended not to save money, but to take the best, albeit expensive, models. Their cost is incompatible with the cost of repairs with the possible replacement of all floor elements.

Preparatory work

Vapor barrier can be installed both at the stage of building a building and during its operation. In the second case, this must be done as quickly as possible. To do this, you need to take out all the furniture from the room, carefully remove the baseboards and floorboards.

Then you need to do the following:

- Remove the insulation from the frame.

- Conduct a survey of the lag and strapping.

- Remove mold, dirt, traces of insects and rodents.

- Fill up existing gaps and holes.

- Treat the wood with an antiseptic and impregnation.

Further work can be carried out after the beams are completely dry.

Required tools and materials

To lay the membrane film, you will need the following set of tools and materials:

- roulette;

- double-sided and aluminum tape;

- scissors;

- furniture stapler;

- a hammer;

- slats for counter battens;

- screwdriver;

- self-tapping screws;

- paint brush;

- antiseptic;

- impregnation.

The calculation of the film and rails is done in accordance with the developed scheme, a margin of up to 15% is made for errors in operation and damage to the material during storage.

Laying vapor barrier for the floor with your own hands

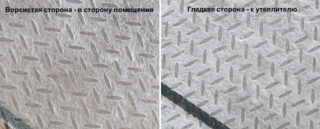

Initially, you need to decide which side to put the canvas on. It should be smooth at the bottom and rough at the top. Usually such inscriptions are made by the manufacturer on the material.

It is recommended to lay the canvas in the following sequence:

- Laying the bottom layer between the lags. Leaving slack for insulation.

- Placement of thermal insulation. Sealing cracks with polyurethane foam.

- Bonding around the perimeter of the room on the walls of double-sided tape.

- Laying the canvas and fixing it with staples. The next strips are superimposed on the established ones by 10 cm, the joints are glued.

- Setting the edges on the walls and gluing to the tape, from which the protective strip is first removed.

- Installation of a counter-lattice.With a step of at least 30 cm.

Finally, the flooring is neatly laid and the skirting boards are attached.

Instead of a vapor barrier, you need to change to a membrane

Moisture is condensed steam from living quarters that enters the insulation from the house due to a leaky vapor barrier (it is almost impossible to make it airtight). Moisture that gets into the insulation is squeezed by films from both sides - it has nowhere to go. Remove the bottom film, leave the air vents open and the insulation and logs will always be dry for many years. In this case, the lower membrane is not needed, it is harmful, condensate accumulates on it. If it does not exist, all the steam that has got into the insulation from the side of the heated premises is calmly evacuated underground and eroded out through the vents.