In construction, strict rules apply to the vertical and horizontal surfaces of residential and ancillary spaces. Without reaching the ideal plane, the finish will not lie down or will look ugly and untidy. The installation of beacons for floor screed helps to achieve the desired result. These small but practical fixtures are essential when pouring concrete floors or leveling deformed slabs in residential, commercial and office environments.

The need to install beacons

Any construction or repair begins with measurements and leveling of surfaces. Its essence lies in the uniform distribution of the solution or bulk materials over the surface so that the difference in heights over the area of the room is absent or is within the acceptable technology limits. The installation of beacons for pouring the floor allows you to create extremely flat surfaces.

Benefits:

- Reducing filling time and improving its quality. The master does not need to control the horizontal lines of the mortar used. In addition, after it dries, you do not have to get rid of irregularities.

- Convenience of laying ceramic tiles. Fragments are easier to fit together, glue consumption is reduced to a minimum, since it is not used to level the horizontal.

- High-quality joining of laminated panels and boards with a lock connection. In the presence of curvature, the connections simply will not snap into place.

- Screed savings. The work is carried out not with visual analysis, but exactly according to calculations and marks, excluding material overruns due to thickening of the fill layer.

The decision not to install beacons can only be made by experienced craftsmen with many years of experience. It is extremely rare for them to take risks when urgency comes first.

Preparatory work

Installation of beacons on the floor is carried out immediately before pouring concrete. Before this, it is necessary to carry out a number of technological measures necessary to prepare the base for the arrangement of the screed.

- Remove the skirting boards and remove the old trim. If it is linoleum, laminate, parquet or solid board, you need to act carefully, since these materials can be sold or reused. With a tile, you can not stand on ceremony and chip it off by any means.

- Examine the base for nails, cracks, cracks and fragile fragments. If there are any, remove them with a chisel. Chisel off strongly protruding protrusions.

- Clean the surface from dirt, dust, oil stains, rust and paint.

- Seal joints, holes and large cracks with cement mortar. Fill small ones with sealant.

- Treat the floor slab with an antiseptic and deep penetration soil. This will prevent mold growth and moisture penetration from underneath.

- Lay a waterproofing coating. Attach it to the perimeter base with any suitable adhesive.

If you plan to pour a screed in a room with decoration on the walls, which you want to keep, you need to fix cellophane or oilcloth around the perimeter at a height of at least one meter.

Definition of zero level

To correctly install the floor leveling beacons, you must set the zero level.

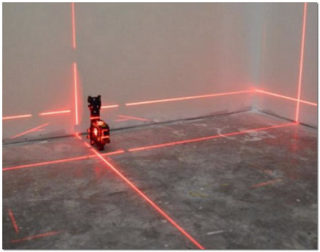

- Using a laser, oil or hydraulic level, marks are affixed to each wall in the same plane.

- The points are connected by lines. This will be an absolute horizontal line.

- The smallest distance to the slab is found. A horizontal line is drawn from it. Ideally, the line should go to the starting point. This is the zero level.

- The distance corresponding to the thickness of the screed recedes from the zero line, another line is drawn. It will be a reference point for the upper part of the lighthouses.

Then you can do the markup and prepare the inventory for the next stage of work.

Varieties of beacons for floor screed

When making a screed, it must be remembered that the subfloor is a surface with a single insulating layer. It is not recommended to violate it. But if you can't do without this, you should use silicone gaskets or mastic in the places where the hardware is screwed into the base. There are several types of orientation jigs that can be used to align the horizontal line before pouring.

With dry screed

Dry backfill is used for leveling and warming floors in multi-storey panel and wooden houses. Expanded clay, perlite, expanded polystyrene, vermoculite, foam glass, as well as their combinations are used. After leveling and tamping, strong plates with interlocking at the edges are installed on top of the screed. A feature of the process is the strong pressure to which the material is subjected during compaction. Therefore, you should choose durable products and fasten them so that the possibility of their movement, breakage and deformation during the laying of the bulk mixture is excluded. The best solution is metal products.

Beacon selection options:

- Galvanized steel CD profiles, which are used in the installation of plasterboard walls and ceilings. Products are installed upward with an opening, which is subsequently also filled with backfill. After the end of the arrangement, the screed remains in its mass.

- Profile pipes. They are characterized by high strength and resistance to deformation. They are used when tamping is carried out by mechanical devices.

- Corner for the formation of door and window slopes. Fastening is carried out with an upward angle. The product serves as a convenient guide for the movement of the rule or the oil level.

Landmarks can be set on hardware or mortar. In the second case, it is advisable to use gypsum-based mixtures that harden within a few minutes.

For semi-dry and wet screeds

The use of such materials does not imply the application of vertical forces. The procedure consists in leveling the mixture until the proper thickness and leveling is achieved.

In such cases, you can make beacons of this design:

- Mortar profiles. Depending on the strength and flexibility of the guides, the fasteners are made pointwise or in a continuous line.

- Supported pipes. As a substrate, wooden blocks, bricks, plastic and plywood scraps are used. Fixation is carried out with quick-drying glue and screws.

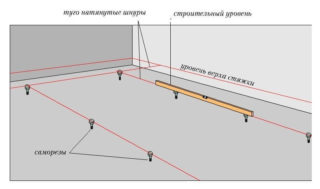

- Self-tapping guides. This method is more time consuming, but allows you to achieve high strength and accuracy of installation of beacons. Fastening is carried out on the base or boards pre-nailed to the floor, located at intervals of 90-100 cm.

- Strips of solidified solution. The guide is a wire stretched between self-tapping screws screwed in one level. After the mixture has hardened, it remains to load the solution and level it with a rule.

- Point mounds. Elevations are made from cement, starter filler or alabaster. It is advisable to reinforce structures in order to avoid breakage of their tops upon contact with the rule.

- By self-tapping screws.This method is used when concrete is poured onto a layer of solid insulation. After the mortar has solidified, the hardware is unscrewed, and the traces of the caps are sealed and rubbed with cement mortar.

When using solutions and adhesives, it is necessary to wait for the crystallization period specified in the instructions for the product. Otherwise, landmarks will be destroyed, and time and money will be wasted.

For self-leveling floors

Pouring polymer floors allows you to get a beautiful, smooth and shiny surface. However, there is one nuance here - the frozen mass is completely or partially transparent. This completely excludes the possibility of using any embedded and removable parts that will be visible through the polymer layer. In such cases, a decision is made to supply benchmarks - professional devices designed specifically for decorative surfaces. They are tripods, inside which there is a bolt, with the help of which the filling level is deduced. The installation process is simplified and accelerated to a minimum. When the mixture is ready for use, you need to install the floor screed beacons and adjust them in height. Immediately after reaching the required thickness of the mortar, the products are removed, and the places of their installation are rolled with a needle roller.

For one-time use, it is not reasonable to buy benchmarks, since they require at least one per square meter. It is easier to rent them for one day, which is quite enough for arranging a self-leveling floor, even over a large area.

DIY installation features

If you pour the screed without using beacons, you get a surface with differences in height, you have to spend time and effort to eliminate the marriage.

It is recommended to adhere to these rules:

- at the beginning of the repair, draw up a detailed, step-by-step work plan;

- put beacons at a shorter distance than the length of the device that is used to level the mixture;

- use durable parts that can withstand the pressure from the solution and the rule;

- do not save on materials, as this can lead to breakdowns and violation of the pouring plan;

- observe the technology for handling fixing compounds, haste in such matters leads to negative consequences;

- if the solution tends to settle after hardening, the beacons will serve as guidelines for re-alignment;

- when using wood as props, it must be carefully treated with hydrophobic agents or several layers of waterproof paint.

Subject to the technology of making screeds for beacons, you can count on obtaining a smooth surface on which you can lay a coating of any complexity of assembly.