A brick stove is not always installed to heat a wooden house. For small buildings, especially summer cottages that are not used all year round, compact metal models are quite enough. But the installation and operation of the latter requires compliance with some recommendations.

- Types of metal furnaces

- Where is the best place to put a stove in a wooden house

- Fire safety rules

- The need for a foundation for a metal furnace

- Varieties of foundations for the furnace

- Foundation installation principles

- Installation of the oven on the floor

- Chimney installation in a wooden house

- How to sheathe the walls and ceiling when installing an iron stove

- Professional advice

Types of metal furnaces

A metal stove is a long burning device. It can be used periodically and continuously. The body of the product is made of alloys that conduct heat well, therefore such a heater heats up the house much faster than a standard brick stove.

Plus iron structures - additional functions. By purpose, they are divided into 3 types.

- Heating - used only for heating. The stove itself conducts the heat. However, the device can be equipped with air pipes that transfer heat to adjacent rooms.

- Cooking and heating - more often found in summer cottages. The design is equipped with a hob, sometimes even an oven. It can be used as a kitchen gas stove and cooked on it.

- Household - this is the name of the most compact models, designed for quick warming up of the room. They are placed in a garage, shed, bathhouse, that is, in rooms where there is no need to maintain a comfortable temperature for a long time.

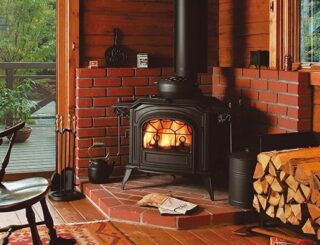

There are also other modifications of the stove. For example, products with furnace doors made of heat-resistant transparent glass are popular: the model replaces a fireplace. Products with nets for stones are chosen in the steam room.

Furnaces are also distinguished by the material of manufacture.

- Conventional steel is used more often for household structures. With prolonged use, the case burns out. The limiting heating temperature is + 400 ° С. If the model is used for less than 2 hours, then + 600 ° С.

- Heat-resistant steel - withstands long-term heating up to + 800 ° С. For the furnace, take steel with a thickness of at least 3 mm. Heat-resistant alloy models are used as heaters and as kitchen heaters. They are compact, very light in comparison with brick ones, they are installed anywhere in the room, but they must be supplied with a chimney.

- Cast iron is an alloy that conducts heat well and accumulates to some extent. Cast iron is very durable, does not lend itself to rust and is not afraid of water and steam. However, such a furnace weighs much more: for the manufacture they take material with a thickness of 6 to 25 mm. In addition, it is effective on an area of no more than 60 m².

All metal stoves are fire hazardous for a wooden house, since the body of such models is very hot.

Where is the best place to put a stove in a wooden house

How to put a metal stove in your home depends on several factors.

- Purpose - an air-heating stove, like "Buleryan", is mounted so that convection air currents move freely through the room. If it heats several rooms, it is mounted in an interior partition and air pipes are connected. The model with a water heat exchanger must be installed so that it acts as the lowest point of the heating system.

- The stove should be installed so that the chimney can be connected with the least difficulty.The latter should go straight to the roof and preferably without turns.

- To heat the stove, to clean it, you need a place. This is provided for in the selection.

- The body should be 110–125 cm away from heating surfaces, especially wooden ones. There should be a free space of at least 125 cm in front of the firebox.

If the stove is equipped with a firebox with a transparent door, it is worth placing it so that you can admire the flame.

Fire safety rules

Wood is a combustible material. When installing a steel or cast iron stove in a house, fire safety rules must be strictly followed.

- Installation is carried out on a protected floor: a metal sheet, a fragment of the floor lined with ceramics, a minerite substrate. The dimensions of such a surface exceed the dimensions of the case by 50–70 cm around the perimeter.

- A distance of 60-100 cm must be maintained between the wooden wall or furniture and the cabinet wall.

- The wall is protected from the stove in a wooden house with a heat-resistant material, like superisol, asbestos sheet. In this case, the distance between the body and the wall is reduced from 1 m to 20 cm.

- The chimney is led out through the ceilings and the roof using metal sleeves filled with non-combustible material. It is recommended that the ceiling in the place where the pipe passes, also insulate with asbestos or metal sheets.

- Leave a distance of at least 1.2 m between the ceiling and the top of the stove. There must be at least 1.3 m from the firebox door to the opposite wall.

If the family has small children, it is recommended to close the metal case with a decorative fence. The best solution in this case is brick cladding.

The need for a foundation for a metal furnace

If the stove weighs more than 750 kg, it is necessary to build a base for it. Often, a cast-iron stove with a volumetric mesh weighs 900 kg. With a weight of 600 kg, it is also advised to make a foundation, since over time, under the weight of the unit, the floor deforms and the stove can warp.

Varieties of foundations for the furnace

A weight of 750 kg or more as a foundation load is not so great. However, the specifics of the design itself limits the choice. There are 3 options.

- Monolithic is the most popular. The depth of occurrence should be below the freezing point, in most cases 50 cm is sufficient. The dimensions of the base exceed the dimensions of the furnace body by 30 cm around the perimeter. Such a foundation ensures absolute stability of the apparatus. In northern latitudes, the depth of occurrence can reach 2 m. In this case, most of the pit is covered with sand and gravel and compacted, and the slab itself is made ordinary.

- Belt - involves digging a trench around the perimeter of the base and the construction of formwork. In this case, less materials are consumed, but the need to construct complex formwork and reinforcement negates the advantages of a lightweight foundation.

- Block - a pit for the foundation is dug as for a monolithic foundation, but filled with bricks or, more often, with large ready-made blocks. The cheapest option.

It is also possible to install the stove on the foundation in the finished building, but for this you will have to first disassemble the floors.

Foundation installation principles

Construction technology is the most common.

- A pit is dug under the stove with a depth of about 50 cm or more and dimensions that exceed the dimensions of the body by 20-30 cm.

- A layer of sand and crushed stone with a thickness of at least 20 cm is compacted to the bottom.

- Formwork is made from boards or plywood and fixed inside the pit.

- Spread out the bottom layer of large pieces of rubble 30 cm thick and fill the voids with fine gravel.

- The formwork is poured with liquid cement-sand mortar.

- Spread the next layer and re-fill with cement. Do-it-yourself operation is repeated until 6-7 cm remains to the floor surface.

- The last layer is poured with a concrete screed. Until the concrete sets - 3 weeks, it is periodically moistened and covered with polyethylene.

Foundation waterproofing is performed more often with roofing material.

Installation of the oven on the floor

If the model is lightweight, it can be placed directly on the floor, provided that there is sufficient thermal insulation.

A sheet of iron, asbestos, minerite is placed under the body of the device. You can lay a square on the floor with ceramics, facing bricks, clinker. The dimensions of the sheet exceed the dimensions of the product by 30-50 cm.

How to decorate the wall behind the stove in a wooden house depends on the nature of the summer cottage. In the bath, the fragment is covered with a screen made of metal or asbestos. However, it is recommended to use more decorative materials in the living room, for example, cladding with ceramics, natural stone, brick.

Protection in the form of a brick barrier is allowed - cutting, or a protective shield made of minerite, which is installed around the stove, with the exception of the side of the firebox.

Often, the stove in the bathhouse or in the kitchen is bricked up, but this increases the total weight of the heater. A foundation may be needed.

Chimney installation in a wooden house

The chimney for an iron stove is chosen from special steel that can withstand high heat and the action of chemically aggressive substances. The chimney can go both horizontally and vertically, and even with turns, but it is more profitable to place it vertically: better draft and less hassle with cleaning.

- Holes for the pipe in the ceiling are made right before installation.

- Adapters - glasses are inserted into the hole in the overlap.

- The ceiling and floor in the attic, if the chimney goes through the attic, is sealed with a metal plate at the transition point.

- The chimney is passed through the sleeve and in the same way taken out to the roof - through the glass. The space around the channel on the roof is also covered with metal.

You can also bring the chimney outside through the wall. The technology is the same.

How to sheathe the walls and ceiling when installing an iron stove

How to protect wooden walls from a stove in a house is determined by the style of the room, purpose and budget. Finishing does not preclude the erection of a protective screen. But if the stove is located far enough - 100 cm, it is allowed not to install thermal insulation, but to choose the material for finishing.

- The most obvious solution is to treat this part of the wall with fire retardants. This does not give a 100% guarantee, but it reduces the flammability.

- A panel made of natural or artificial stone looks beautiful.

- In a loft, techno and rustic room, brick cladding is quite suitable - textured or facing.

- A drywall sheet serves as quite sufficient protection.

It is forbidden to use flammable coatings for finishing, such as oil impregnation, varnishes, oil wax.

Professional advice

Steel and especially cast iron stoves can have very beautiful designs. Such products should not be bricked or protected with a screen. You need to worry about their successful placement in advance.

- A structure for heating several rooms can be placed directly in a wall or partition. Such an installation is more complicated and involves bricking.

- When installing the stove and chimney, make sure that all structural units are freely accessible. There should be no difficulty in cleaning and inspecting the elements.

Heating a wooden building with a metal stove is a completely rational solution for a country house or summer cottage. The structures are lightweight, compact, very effective, but a number of rules must be followed during installation.