The owners, as a rule, carry out the construction of the bath on their own. Self-assembly of sandwich pipes in a bath is a simple and technologically advanced way of arranging a chimney. This design has advantages and disadvantages over other options for smoke removal systems.

- Requirements for smoke extraction systems

- Conditions for the correct operation of the chimney

- Varieties of chimneys

- External option

- Internal structures

- What material to choose

- Asbestos cement

- Black metal

- Brick

- Ceramics

- Glass

- Sandwich elements

- Arrangement of an internal chimney

- Design

- Preparing transitions

- Installation

- Frequent mistakes

Requirements for smoke extraction systems

Chimneys are needed not only for the removal of combustion products outside the premises of the bath. In addition to this task, they must meet the following requirements:

- be sealed so that poisonous gases do not seep into rooms where people are;

- reduce the likelihood of reverse thrust formation;

- ensure energy saving and energy efficiency, i.e. promote minimal heat loss for heating the outside air;

- be easy to maintain, namely, do not obstruct the removal of soot and soot;

- exclude the ignition of nearby combustible objects and roof;

- create conditions for a minimum amount of condensate on the inner surface of the pipe;

- reliably protect against the risk of burns in case of accidental contact.

Fulfillment of all requirements is achieved by correct design, selection of materials and adherence to installation technology.

Conditions for the correct operation of the chimney

To perform all functions, when installing sandwich pipes for a chimney in a bath, a number of conditions are observed:

- the minimum height from the grate of the stove to the upper cut should not be less than 5 meters;

- over the entire length, more than 3 turns at an angle of more than 30 ° are not allowed;

- the length of the horizontal section should not exceed 1 meter;

- the inner diameter is calculated based on the volume of the combustion chamber, if the wood-burning stove is homemade;

- the clearance must not be less than the outlet for prefabricated ovens.

Fire safety requirements affect the design and the materials selected.

Varieties of chimneys

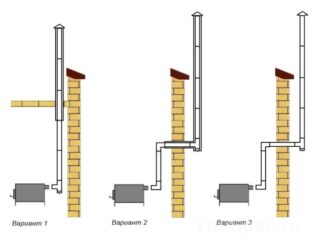

According to the method of installation, there are internal, external, combined chimneys. The type is determined by how much of the pipe is inside or outside the room. Each type has advantages and disadvantages.

External option

The structure consists of a small vertical inlet, a horizontal (or inclined) outlet through the wall and the outermost part, fixed on the wall or built as an independent structure.

Advantages of an external combustion products removal scheme:

- low probability of fire - the hot chimney does not pass through the wooden floor and roof sheathing;

- ease of construction if sandwich pipes are used;

- the cost of thermal insulation of transitions through floors and roofs is reduced;

- the chimney does not take up much internal space.

Outdoor chimneys have disadvantages, especially noticeable in the cold season:

- the pipe heats up for a long time, which is why the thrust does not arise immediately;

- in winter, condensate flows down the inner surface, which leads to corrosion of iron pipes or the gradual destruction of brick ones;

- cold walls slow down the combustion process, some of the substances are deposited on the inner walls in the form of carbon deposits;

- due to carbon deposits, frequent cleaning of the chimney is required.

Homemade metal chimneys are unattractive on the facades of buildings, so you have to buy factory components if appearance is important.

Internal structures

The scheme for constructing an internal chimney corresponds to the name

In the vast majority of cases, the chimney runs vertically upward, with the intersection of ceilings and roofs.

The internal option has significant advantages:

- lack of turns improves traction;

- the chimney heats up quickly, which reduces soot and soot deposits;

- for the most part there is no temperature difference between the outer and inner surfaces, which reduces the amount of condensate flowing down;

- part of the pipe is inside the room, accelerating the heating of the steam room, which reduces energy consumption.

The disadvantage is the increased cost of thermal insulation of the intersection of the floor and the roof. They buy ready-made cuts or make them on their own.

The mixed type refers to the smoke exhaust ducts located inside the brick walls. Due to the complexity of the design and the required large wall thickness in private buildings, this type of chimney is rarely found.

What material to choose

For the manufacture of chimneys, factory and home-made elements are used.

The rules for the arrangement of chimneys and the requirements for the microclimate of the premises are described in the Code of Practice 60.13330 of 2016. The title of the guidance document is "Heating, Ventilation and Air Conditioning".

The code defines the standards for the construction of stove heating only for places with a constant stay of people, however, it is not recommended to ignore the norms in rarely visited baths. Failure to comply may result in injury or fire.

Popular materials for the manufacture of chimneys are: asbestos-cement products, ferrous metal, brick, ceramic pipes, stainless steel. Exotic version of glass chimneys.

SNiP 41-01-2003 allows the use of heat-resistant concrete, refractory bricks, asbestos-cement or sandwich elements made of stainless steel for the manufacture of pipes.

Installation of chimneys from other materials violates the requirements of SNiP, and the owner of the building will be recognized as the culprit of the damage.

Asbestos cement

The main positive side of asbestos-cement pipes is their low cost.

Pipes are made only on production lines; products are distinguished by precise geometric dimensions and high-quality composition of raw materials.

As additional elements, the industry produces only straight couplings, which makes it difficult to manufacture turns.

For cutting, use a hacksaw for metal or a grinder with a cut-off wheel for a stone - this simplifies the installation of a bath stove with a chimney with your own hands.

Possible use cases:

- straight vertical sections of the internal chimney;

- vertical lines in external layouts.

In the second application, the asbestos-cement pipe must be insulated:

- wrapping with roll materials with the subsequent installation of protective metal covers;

- brickwork.

Such structures dramatically increase the cost of construction, which minimizes the savings when buying the asbestos pipe itself.

Black metal

Thin sheets of ferrous metal get red-hot during the heating process, which can cause burns and fires. At the same time, iron burns out quickly, and leaked gases can cause poisoning.

It is not recommended to make a chimney of ordinary iron, even in a rarely heated bath. After a short time, you will have to replace the entire structure.

Brick

Brick chimneys are inherent in capital buildings.

Among the positive properties are noted:

- low temperature of the outer wall, which excludes burns and fires;

- attractive appearance;

- long service life due to the large wall thickness and the minimum amount of condensation.

These designs have many disadvantages:

- the construction of a capital foundation will be required;

- the walls must be carefully plastered - soot quickly settles on rough surfaces, requiring frequent cleaning;

- the pipe heats up for a long time without giving off heat inside the premises, which leads to an increased consumption of firewood;

- building external chimneys will require the skills of a bricklayer.

In addition, high costs will be required for the purchase of building material.

Ceramics

Ceramic chimney pipes must be taken as a marketing gimmick.

In reality, it will not work to build a chimney only from ceramic pipes. It will require an external protective layer of brick or insulation.

Thus, ceramic parts are used as chimney inserts.

Among the advantages of such a constructive solution:

- smooth inner walls, on which soot is weakly retained, which reduces the frequency of cleaning:

- low thermal conductivity contributes to a small amount of condensate, helps the quickest heating of the pipe and the exit of the furnace to the operating mode.

In a similar way, polymer chimneys work, which also represent nothing more than liners in the main pipe.

Glass

Glass in chimney pipes is exotic, the distribution of which is limited due to the high price.

Glass pipes cannot be put on the furnace outlet; a transition of about 1 meter from other materials is required.

Sandwich elements

Assembling a pipe for a bath from sandwich elements is within the power of any builder.

Sandwich pipes consist of three layers: external and internal from stainless steel, between which there is a layer of thermal insulation. Elements are produced in various diameters, which allows you to select products for furnaces of various capacities.

To create a chimney of the required configuration, parts of various lengths and additional elements are purchased, which are ash pans, corners and turns.

Material advantages:

- fire safety, since the outer layer does not heat up to a dangerous temperature;

- the material does not emit harmful substances;

- simple assembly;

- a price comparable to the arrangement of insulated pipes made of asbestos cement;

- minimum amount of condensation due to good thermal insulation;

- smooth inner walls;

- attractive appearance;

- availability of prefabricated and manufactured cuts.

When self-assembly, you must pay attention to the recommendations of the manufacturer and experienced builders.

Arrangement of an internal chimney

The erection consists of several stages:

- design;

- preparation of crossings through building structures;

- installation of brackets;

- assembly of the structure;

- roof and floor insulation;

A test run ends the process.

Design

The operability and ease of maintenance of the chimney depends on the correctly chosen solution.

An important parameter taken into account in the design is the inner diameter of the pipe. The minimum internal section depends on the power of the furnace: for devices up to 3.5 kW, choose a section of 140x140 mm or an internal diameter of 150 mm. Furnaces from 3.5 to 5.2 kW are equipped with chimneys 140x200 mm (or 200 mm in diameter).

Gate valves for any furnaces should not be less than 15x15 cm. The distance from the pipe to the walls made of combustible materials is 260 mm, to brick or block structures 200 mm.

After a test furnace, the temperature of the surrounding objects is measured. If it is above 40 ° C, then a non-combustible heat insulator is additionally laid.

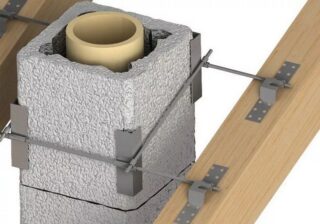

Preparing transitions

Having decided on the location of the stove and chimney, they begin to make solid holes in the ceiling and roof. Plumb lines are used so that the chimney is located strictly vertically.

The diameter of the holes is 400 mm larger than the outer diameter of the pipe, which is necessary for arranging thermal insulation.

They purchase factory cuts or make a box of the required size, which, after installing the pipe, is filled with a heat insulator.

Installation

Installation of a chimney from sandwich pipes through the roof in the bath begins from the bottom, gradually rising towards the roof.

Joints are made "by condensation": the joints of individual parts should not prevent the drops from rolling down from top to bottom. The upper pipe should go into the lower one.

If necessary, the structure is attached to the walls using brackets.

At the end of the installation, the cutting is insulated, the roof is waterproofed and the removed roof elements are installed.

If there are buildings made of combustible materials within a radius of 5 m from the head, a spark arrester must be installed. The same element is required for a roof made of combustible materials.

The pipe outlet is equipped with a deflector or an umbrella head.

Frequent mistakes

Possible errors when installing a pipe on a stove in a bath are associated with non-compliance with the installation technology:

- the pipe must be collected "by smoke" and not "by condensate";

- use materials not permitted by the Code of Rules;

- do not comply with the recommended number of turns or their maximum angle;

- do not insulate the structure;

- do not make thermal protection of combustible walls, do not use cuttings for ceilings.

Chimneys from sandwich pipes, assembled in compliance with the technology, are safe for health and cannot cause fires. Chimneys from such elements are comparable in cost to other options, but they last longer, have an attractive appearance, and are assembled in the shortest possible time.

Comrades, do not get fooled by advertising. Make only a brick pipe in the bath. In this case, the brick can be laid on its side. Everything works. The main thing is to have a good solution on which to lay the brick. All metal chimneys are simply dangerous with fire. After 4-5 years they need to be changed. Brick can always be shifted. There are situations where the oven code leads.