When building a bath in a summer cottage, there is no point in equipping a capital structure. It is more expedient to install a frame structure, which is no worse to cope with the performance of the functions assigned to it. It is erected from a well-dried timber or boards with a cross section of at least 50x100 mm. If necessary, this structure can be thoroughly insulated and the sauna can be used at any time of the year.

General rules for warming a frame bath

The frame bath belongs to the category of pre-fabricated structures, the walls, floor, ceiling and roof of which are a cake made of insulation, as well as layers of steam and waterproofing. Insulation of such a frame structure is carried out as it is constructed, starting from the walls and floor. The last to insulate the inside of the bath - the ceiling and the steam room.

Before starting work on insulating the frame bath with your own hands from the inside, install and insulate the outer walls, and upon their completion, equip a ventilated facade. So it will be possible to remove moisture outside.

All gaps and gaps between the insulation boards must be filled with polyurethane foam.

Insulation types

Materials used as insulation for a bath must have low thermal conductivity, moisture permeability, and flammability.

In addition, they must provide a long service life and be environmentally friendly. These can be organic (peat, wood waste, reeds, etc.) and inorganic materials.

Organic

Among the materials of natural origin, plates are most often used as insulation:

- wood fiber;

- reed;

- chipboard;

- peat.

They also include slabs of kostramite and wood concrete, made using lightweight concrete. It is also possible to use fiberboard boards, which are based on a compressed hardened mixture of wood chips and cement.

Inorganic

Mineral or glass wool is used as a heater of inorganic origin, as well as finished products based on them:

- soft boards and mats with synthetics;

- rigid slabs with bitumen;

- perlite materials (perlite concrete, glass and gypsum perlite).

Glass wool is also used to make stitched mats and slabs on a special resin.

Heaters made of inorganic materials are resistant to any external influences, practically do not wear out and do not rot.

Plastic heaters

Plastic heaters are widely used. These include:

- foams;

- poroplasts;

- honeycomb.

They are characterized by good thermal insulation properties, high moisture resistance and low weight.

Heat insulator selection

The choice of insulation for a bath depends on the availability of material, financial capabilities and personal preferences of the owner. Affected by the presence of certain skills in those who are engaged in construction. Most often they choose as insulation for a frame bath:

- reed slabs;

- basalt wool;

- linen fiber mats;

- a mixture of sawdust with cement, gypsum or clay;

- synthetic materials.

Reed slabs are of natural origin and have excellent characteristics. They are characterized by resistance to high temperatures and a wide variety of design sizes. All this, along with a low weight, allows you to choose the most suitable option for a specific version of a frame bath. The undoubted advantage of reed slabs is also the complete absence of harmful secretions even at the highest temperatures.

Mats from pressed flax fibers began to be used as a heater relatively recently. They do not contain any additives, so they are absolutely harmless to health. The dense compaction of the fibers ensures a high density of the material and the ability to save heat. In addition, linen mats perfectly absorb and release moisture.

Wood sawdust mixture with cement, plaster or clay - the most affordable type of insulation. With all its variants, one proportion is used - 10: 1. This mixture is used to insulate any part of the bath, however, certain rules must be followed.

Basalt slabs (rolls) - one of the most popular materials used to insulate baths. Differs in increased service life, high density, low water absorption and long-term preservation of its characteristics. In addition, it is safe for human health even at high temperatures.

Of synthetic materials the most popular is polystyrene. It has a cellular structure, does not allow moisture and cold to pass through, and also practically does not load the foundation. Polystyrene has a long service life and does not emit fumes hazardous to health when heated. The only drawback is that it needs to be laid on a pre-aligned base.

Warming of the main elements of the frame bath

Thermal insulation of a bath is a laborious and complex process, during which it is necessary to take into account a wide variety of factors. If the bathhouse is operated constantly, it can be insulated, guided by the principles typical of ordinary residential buildings. If the bath is used periodically, moisture will accumulate in its structural elements. This applies only to the steam room, the rest of the rooms can be insulated using traditional methods. In any case, the insulation of the frame bath begins from the floor and walls, gradually rising to the ceiling.

Floor insulation

They start with the simplest operation - warming the space under the floor. A layer of expanded clay or furnace slag is poured. In dry rooms, a solid floor is laid, reliably retaining heat. Lay in succession:

- lags;

- sub-floor boards;

- insulation, which can be foam or basalt wool slabs;

- waterproofing film.

Further, in dry rooms, a finishing floor is mounted from a grooved board or ceramic tiles.

In the steam room, at least two layers of waterproofing are laid on a layer of insulation, on top of which a concrete screed is then made with a thickness of at least 5 cm.To increase its strength, the screed can be reinforced with a steel mesh. After the concrete hardens, proceed to the installation of the finishing floor.

Wall insulation

Thermal insulation of the walls of the bath does not present any particular difficulties. Thermal insulation is laid on the mounted lathing, which is then covered with a layer of hydro and vapor barrier, and then sewn up with clapboard or siding.

The insulation layer must be at least 100 mm. In some cases, you can use insulation 50 mm thick, while laying it in two layers. For additional protection, foil is placed between the layers.

Thermal insulation of a steam room in a frame bath is carried out taking into account a number of features. For example, attention is paid to the area around the stove. Insulation and waterproofing are mounted on the walls, and then thin sheet aluminum or foil is additionally laid.It would be useful to additionally clad the walls around the stove with refractory bricks, which will prevent possible ignition of the thermal insulation.

Ceiling insulation

The ceiling in the bath is insulated as follows:

- A PVC membrane is laid, which is designed to remove moisture to the outside.

- A foil membrane is attached to the floor beams to retain heat inside.

- Install the crate.

- Insulation is mounted between the battens of the battens, the layer of which should be twice as thick as on the walls.

- Laying waterproofing.

- Lay a layer of foil-clad material (vapor absorber) that will reflect heat from the ceiling surface.

- Lay the topcoat (cladding panels or wooden lining).

To release air and condensate, an exhaust hood is installed near the ceiling or a special hole is made.

It is advisable to install a stainless steel screen above the stove. This will protect the ceiling from overheating and deformation.

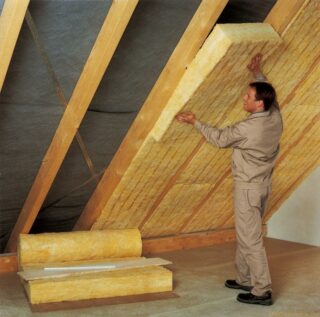

Roof insulation

Reliable heat and vapor insulation of the ceiling will not allow heat loss through the roof, therefore, after the roof is erected, four layers of insulation will be enough:

- plank flooring;

- thermal insulation material;

- vapor barrier material;

- external cladding.

When arranging the roof, traditional methods of laying insulating materials are used.