Uninsulated ceiling is the main part of the building that allows heat to pass through. When building a bath, it is necessary to take care of the thermal insulation of this structure, since it is important to maintain a high temperature in the premises for a short time.

Do I need to organize the insulation of the ceiling

Thermal insulation of the wooden ceiling in the bath is necessary for the following reasons.

- The temperature in the steam room is higher than the temperature in the living room. To retain heat, it is necessary to insulate the floor, ceiling and walls.

- The steam room maintains a humidity of 50–70%. To prevent the penetration of condensate into the ceiling cake, it must be insulated and waterproofed.

- The tree in the bath is treated with fire retardants, antiseptics, special compounds against decay and mold. All of them are partially destroyed at high temperatures and release harmful substances. This can be prevented by insulating the ceiling.

Isolation can be carried out in the attic and inside the bath.

Features of heaters

A number of requirements are imposed on thermal insulation in a bath:

- high temperature resistance;

- resistance to water - partially solved by waterproofing;

- health safety;

- mold resistance.

In practice, the requirements are met only partially, and a more complete effect is achieved by a combination of various materials.

The following ceiling heaters are used for the bath.

- Slabs - polystyrene, penoplex. The material is easy to install, is not afraid of moisture, steam, temperature changes, but its vapor permeability is very low. Which makes it difficult to ventilate the room. This disadvantage is compensated for by installing good ventilation.

- Roll - mineral, basalt wool, glass wool. Loose fibrous material with high thermal insulation characteristics. It can withstand high temperatures. It is completely safe, has good vapor permeability, but mineral wool is afraid of water. Therefore, such insulation is carefully waterproofed. Since such an operation is still performed, this is not difficult.

- Bulk materials - kerazmite, perlite. Very cheap material in the form of light porous stones. It is poured from the side of the attic space in a thick layer. They are not exposed to the action of water and steam, and therefore such thermal insulation does not need protection.

The choice of material is influenced by the size of the bath, material, financial capabilities, ceiling design.

Varieties and design features

The ceiling cake in the bath is chosen depending on the size of the room and the type of building.

- Plank - rough boards serve as its basis. They are attached directly to the walls. There are no beams and logs. The thermal insulation and waterproofing foil is bonded directly to the subfloor. The option is very cheap and affordable. It has significant drawbacks. Firstly, this is only suitable for small rooms, since long boards will begin to sag over time. Secondly, the attic can no longer be used.

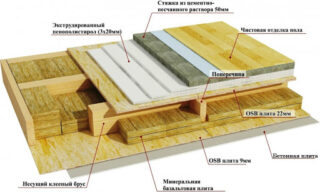

- A false ceiling is more versatile. The basis is a frame made of lags or beams. Such a structure is hemmed from below with insulation, waterproofed and trimmed with boards or clapboard.The false ceiling can be insulated from the outside: in this case, the finishing boards are fixed from the bottom to the beams, and the heat insulator is laid from the attic or attic side.

- Panel / panel board. The ceiling is formed by finished panels. The latter act as a composition of inner sheathing, vapor barrier, insulation, waterproofing of the external ladder - sheathing from the attic side. Shields are installed on the top harness and fixed to the walls.

For panel boards, it is preferable to use mineral wool as thermal insulation, since it weighs little.

The choice of insulation

Ceiling insulation for a wooden bath is selected according to its thermal insulation characteristics. The same degree of insulation is created by 9 cm of polyurethane foam, 15 cm of mineral wool and 165 cm of expanded clay concrete.

The method of insulation is also important - from the top or from the inside.

How to insulate outside

For external thermal insulation, that is, from the attic side, you can use mineral wool, foam plates and bulk materials. The latter are much cheaper.

- Expanded clay is a porous material obtained by firing clay. Small, light stones create a loose pad that retains air well. Expanded clay insulation is most often used for concrete floors. Their bearing capacity is very high and the material can be poured in a thick layer.

- The grandfather's method of thermal insulation is a mixture of cement with sawdust or hay. The addition of such a material makes the solution heat insulating. Clay may be used instead of cement.

- Perlite is a volcanic ore of almost the same density. Its porosity reaches 70–90%.

- Penoizol - loose. An organic insulator produced in the form of granules. Non-flammable, not afraid of moisture and does not absorb it. Penoizol is more expensive, but more effective.

Bulk insulation is laid on the rough flooring of the attic between beams or logs and waterproofed.

How to insulate from the inside

It is recommended to use rolled fibrous materials to insulate the wooden covering in the bath, although the latter are more prone to getting wet. However, in this matter, the vapor permeability of the insulation turns out to be a more important parameter.

Mineral wool produced from basalt, other rocks, and slag. Depending on the source, the thermal conductivity and strength of the fibers differ. The fibers stick together to form a loose, airy structure. It is distinguished by high heat and sound insulation properties, allows air to pass through, does not burn, which is very important for a bath, and does not grow moldy.

The disadvantages include poor resistance to high humidity. When wet, the material loses its properties, drying does nothing. In addition, mineral wool attracts rodents.

For steam rooms and saunas, they often choose foil insulation... It is made of expanded polypropylene or polyethylene coated on one side with a thin aluminum sheet. This finish retains heat due to the porous texture of the insulation and thanks to the foil: the aluminum layer reflects infrared radiation into the room, thus preventing heat loss.

Foil heat insulator allows you to hem the ceiling with a much thinner layer of material. At the same time, he is not at all afraid of water, steam, high temperature.

Popular slab insulation - Styrofoam... It is produced in the form of sheets that fit end-to-end on the ceiling. The material retains heat much more efficiently than mineral wool, but it is vapor-proof and flammable. Insulation with such material is allowed only with a sufficient ceiling height. This option is preferable in steam rooms, where electric ovens are installed without a chimney.

Installation of thermal insulation

The instructions for installing thermal insulation from the inside are the same for all materials.

- Insulation can be placed between logs or beams. If a flooring ceiling is made, a frame is laid on the rough flooring.In this case, the height of the bar should correspond to the thickness of the insulation.

- The surface is waterproofed. Usually they use plastic wrap, but it is better to take membrane materials.

- The insulation is fixed. Plates can be glued, mats are placed in a spacer. Sometimes they are fixed with special dowels.

- A vapor barrier film is laid over the thermal insulation. The joints are glued with tape.

- A counter-lattice is stuffed, since a ventilation gap must be maintained between the ceiling cake and the finishing flooring.

- Fix the lining, boards on the counter-lattice.

Outside, the ceiling in the bath is insulated in the same way, but in the reverse order.

Dry method of insulation

An interesting method was proposed by Yu.P. Sosnin. and Bukharkin E.N. - dry insulation of a cold attic.

- The grooved boards are installed on beams and treated with linseed oil twice.

- Sheathed with clapboard, leaving a gap of 3 cm - to drain moisture.

- Waterproofing is laid on top of the structure - plastic wrap, roofing material. It is best to take foil-clad material.

- The next layer is sand or slag 20 cm thick.

In such a cake, it turns out, as it were, 2 layers of insulation - air and sand.