There are several ways to install support pillars during the construction of a fence: driving into the ground, concreting, backfilling. These methods are not interchangeable. A method is chosen taking into account the nature of the soil on the site and the weight of the fence.

When filling posts is advisable

Backing up posts for a summer cottage fence means filling the hole under the post with crushed stone or other hard material - expanded clay, brick. This option is much more reliable than simply digging into the soil, even with compaction. Crushed stone dries quickly during floods and after rain, since water does not linger in the loose rock layer. Accordingly, the pillars are not washed away by groundwater, and the fence made of profiled sheet or picket fence does not deviate from the vertical.

Backfilling is used in the following cases:

- Too loose soils - light loam, sandy loam, sand. Such soil absorbs moisture in winter, the water freezes, expands and literally pushes the column out.

- Heavy soils - prone to freezing.

- With a high level of groundwater, crushed stone acts as a kind of drainage.

Recommendations are relevant for regions with low winter temperatures.

Advantages and disadvantages of butting

Dry concreting technology has a number of advantages:

- The main advantage is that the technique is universal and is used to install pillars made of wood, iron, plastic, asbestos cement.

- Backfilling ensures the stability of the fence in all soils.

- The crushed stone layer acts as a drainage cushion and removes flood and rainwater from the fence.

- The pillow prevents the soil from moving when the temperature changes. Crushed stone or brick acts as a buffer between the soil and the pillar.

- Efficiency - crushed stone is cheap, and such installation takes a minimum of time. In addition, after backfilling, there is no need to wait for the material to set, as it happens when pouring concrete.

The cons are as follows:

- Labor intensity - a hole 70 cm deep must be filled with a stone and compacted. This is hard work.

- Instability to strong wind loads - under really strong gusts of wind, the pole hesitates and looses.

When backfilling, crushed stone is mixed with sand to give the base some plasticity. This compensates for ground movements around and below.

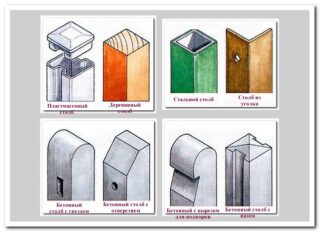

The choice of pillars for installing a fence without concreting supports

You can do without concreting on any soil. However, the material of the support is of some importance.

Crushed stone provides a good base for a relatively light stance. The stone backfill simply will not hold a concrete rack 2 m high, such supports need to be concreted. The rest of the options are quite suitable for backing up:

- Iron pipes - both round and shaped. They are installed using the same method. However, for fixing the mesh or lags, pipes with a square cross section are more convenient.

- Piles are metal or concrete pillars designed for heavy loads. With a sufficient immersion depth, crushed stone backfill quite copes with the role of the foundation.

- Timber or log - easily held by a stone layer.

Backfilling is especially recommended if iron pipes or profiles are used. The crushed stone layer quickly removes water, so the metal is less exposed to moisture and rusts much more slowly.

Required tools and materials

- shovel for digging a hole;

- tape measure and plumb line to check the verticality of the post;

- scrap or log for ramming;

- bucket with water;

- ravine sand.

You can fill the hole with crushed stone, gravel, limestone.

Post backing material

More carefully you need to approach the issue of choosing crushed stone. According to GOST, the minimum allowable stone size should be 5 mm, and the minimum allowable strength should be M200. In addition, it is necessary to take into account the resistance of the material to frost - at least F250.

The following breeds are used:

- Granite crushed stone - provides resistance to load bearing.

- Limestone - is obtained from sedimentary calcium rocks. Less durable, therefore it is used for backing only wooden posts.

- Gravel is mined by screening quarry soil. It is somewhat inferior in density to granite.

- Crushed concrete - made by recycling old concrete structures. This material is recommended for use on swampy soils and loams.

Brick fragments are often used. However, such a mixture obtained by hand is rarely uniform.

Preparing for backing

Shooting of fence posts begins with marking the site and calculating materials. Often, markup is done before calculations. Since this allows in practice to determine the required number of supports.

- Then the immersion depth is calculated depending on the type of soil.

- Dig holes under the pillars. The diameter of the trench should exceed the size of the support by 12 cm.

- Calculate the volume of each pit, calculate the amount and amount of crushed stone and sand required.

The calculated volume should be increased by 15%.

Rules for backing up pillars for a fence with rubble

The technology is very simple.

- A layer of sand, expanded clay and crushed stone 10-15 cm high is compacted to the bottom of the pit. It serves as drainage.

- Install the support. If it is a wooden rack, its lower part is coated with bitumen, wrapped with roofing material. If it is metal, it is treated with an antiseptic and a primer. A plug is placed on the pipe.

- Temporarily strengthen the post to keep it upright.

- The filling is done in layers: 10-15 cm of crushed stone or gravel is laid and covered with sand. Then fill in with water and repeat the operation.

- Experts advise to pour the top layer of the base with concrete to strengthen it.

After the installation of the pillars, the corrugated board, the lattice, the mesh-netting are fixed.

Backing up the support posts is a simple and reliable installation method. This is how metal and asbestos-cement pipes, wooden racks, metal profiles are installed. The technology is used on any soil.