To make a door to the bath with your own hands, you need to imagine what requirements are imposed on the structure in connection with the conditions of its operation. Usually at least 2 canvases are installed: an external one and one leading directly to the steam room. Large rooms have other doors (for example, leading to the dressing room).

Basic requirements when installing doors to a bath

The main purpose of door structures in this case is to keep heat in the room. It should not penetrate outside through the canvas or crevices next to it.

The door to the steam room must have a wooden handle. You can also make a simple flap to prevent swinging. Other materials will not work for these purposes: metal can burn the hand, and plastic will emit harmful fumes under the influence of high temperatures. The external entrance door can have a handle and a lock made of steel, coated with anti-corrosion compounds.

It is also important that the structure is not subject to deformation under the influence of humid air and high temperatures.

All used wooden elements should be treated with antiseptics and flame retardant impregnations. Oily and varnish compositions cannot be used: in conditions of high temperatures, poisonous substances will be released. We need special impregnations suitable for bath rooms.

Internal doors are placed at a certain height (about 5 cm) from the floor, but this can be neglected if a ventilation system is planned to be installed in the building.

The structure leading to the steam room should swing outward. This is important as it makes it easier to get out of the premises in case of dangerous incidents.

Door parameters

Before you make the door to the bath, you need to imagine its size. For better heat retention, it is recommended to choose dimensions slightly smaller than usual. The length of the structure in this case will be 1.5-1.8 m, and the width - 0.65-0.7 m. Tall people will need to bend down when entering the room, but such parameters minimize heat loss. In addition, there will be less material consumption. The optimal thickness of the wooden sheet is 0.1 m.

Types of doors for a bath

In the old days, bath doors were made of solid wood. Now the use of glass, metal, as well as modern types of building materials is becoming more widespread. External structures are also made of metal-plastic.

From glass

For door structures, only tempered glass is used, which is characterized by increased strength and less injury risk compared to conventional glass. The sheet thickness is usually 8 mm. This cloth is especially popular in the equipment of saunas. The Russian steam room is distinguished by high air humidity, so condensation settles on the glass, it has to be constantly removed with a rag. The canvas can withstand temperatures up to 300 degrees. Also, the material is good in that it does not swell at high humidity and is not affected by fungal and mold colonies, unlike wood. The installation of such a door is carried out in a box that is not equipped with a sill. As a result, a clearance of 0.5-0.7 cm is obtained between it and the floor.

With double-glazed windows

At the entrance to the steam room, you can put a wooden structure equipped with a double-glazed window. The building material in such products is carefully processed, as a result of which it does not swell when exposed to water and does not crack. It is easy to take care of the door leaf - it is enough to wipe it with a rag. Moisture is removed from double-glazed windows with a dry cloth after the end of the bath procedure. As needed, they are cleaned with a window cleaner.

From the lining

The lining is attractive for the manufacture of doors due to its lightness. The load on the fasteners when using this design will be less than when installing a board from an array. But the material is not very durable, so a frame made of bars is needed for the door. Sheets are stuffed on it from both sides. It is recommended to fill the gap between them with insulation.

The choice in favor of lining is often made also because of its price: even linden material is not very expensive. Also, a plus is the minimum susceptibility to cracking and other deformations associated with the peculiarities of the microclimate of the bath.

Handles and other hardware components are poorly held in the doors from the lining, therefore, parts for reinforcement are laid in the configuration.

MDF

From an environmental point of view, this material is not the best choice. Under the influence of high temperatures, it releases compounds harmful to humans. Therefore, it is not very suitable for interior doors. The same applies to plastic structures and fittings.

Making and installing a door to the bath with your own hands

The easiest way is to make a door for a bath with your own hands from a solid wood. Linden and ash are best suited for this. Coniferous building materials are not the best choice, as resin in a high temperature environment can burn the skin. If, nevertheless, it is decided to use such raw materials due to the unavailability of other options, they are processed to prevent the release of gums. The opening for the door is provided at the drawing stage.

Instructions for making a bath door with your own hands:

- Smooth grooved boards with a thickness of 50 mm are prepared. You can do this yourself or purchase building materials in the store.

- They put them in a row and trim. From the end parts of them you can see the annual marks. The adjacent boards are laid so that they have opposite directions of the rings. This makes it less susceptible to moisture.

- Marks are made for the selection of grooves (the latter should have a truncated conical shape). These elements will go deep into 25-50% of the total thickness of the board. The lower part is 50 mm wide, the top 35.

- Saw the grooves at 45 degrees. To control the uniformity of the slopes, a bar that was cut with the specified bevel angle is suitable.

- The wood is removed between the cuts and thick (at least 50 mm) keyboards are mounted.

- The structure is assembled and its evenness and strength of the joints are assessed.

- The dowels are punched into the groove slots (you can use an adhesive). Their endings need to be cut off.

After that, you can proceed with the installation of the structure. First you need to choose the dimensions. If the door itself is 8 cm thick, for box racks this parameter will be 5 cm, and the width - 12 cm. It is necessary to prepare a pair of vertical and transverse elements. The latter should have a section of 8x5 cm.

Step-by-step guide for work execution:

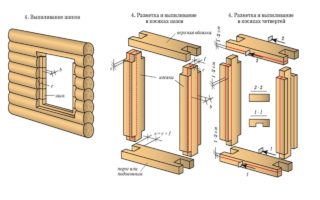

- The bars are prepared and the quarters for the door body are cut into them with a chisel. They should be parallel to the longitudinal sides of the elements and form a single plane. This minimizes the chance of gaps appearing.

- The outlines of the latter are marked on the hinge stand. Landing sites are being milled.

- Large blanks are laid out on the table, quarters are placed on top. On the hinge side, a clearance of 2-3 mm is made, in other cases - 5 mm.For this, wood wedges are used. This is necessary so that the structure opens easily.

- Measure the length of the contour lines in accordance with the distance between the sides of the verticals. Excess trimming is done with a hacksaw.

- Make quarters in the corners and start assembling the box. Having attached the canvas, the hinges are mounted in their proper places and a gap is created using wedges. Check the correctness of the corners of the structure (they must be perfectly straight).

Self-tapping screws are used to fasten the box (pair per joint). To prevent the nearby places from cracking, the holes should be 0.5 mm wider than the maximum section of the self-tapping screw (in the fastened quarter, on the contrary, they are 2 mm narrower). If the structure opens easily, and no gaps appear when closing, the work is done correctly.

Possible installation problems

You should not make a door to the steam room immediately after assembling the log house. You need to wait at least six months, otherwise the structure will become distorted over time. Do not immediately fill the gaps of the door frame with foam, otherwise, as the building shrinks, the tightness will be lost. At first, a simple tow is used for this purpose. After 3-5 years, the foam can be used.