Installing sliding gates for a garage or garden area is attractive because there is no need to regularly clean the snow in the surrounding area. In addition, the design does not constrict the entry area. It is quite possible to mount such a system with your own hands, although it is more difficult than swing gates.

The device and principle of operation of sliding gates

Having decided to install sliding gates, you need to decide on the choice of a mechanism that allows the canvas to move along the plane of the fence, freeing up space for residents to enter or a vehicle to enter. There are such varieties of them:

- Rail mechanism with rollers attached to the bottom of the sash frame. The weight of the canvas is distributed between them. The sash moves along the guide. The design does not set limits for the values of the height and length of the web. The latter can be integral, or consist of several sections.

- The cantilever type of sliding gate also has rollers, but here they are fixed motionless. The canvas moves along them. This type already imposes restrictions on the dimensions and weight of the sash (it should not be too heavy), which affects the choice of materials.

- Suspended model, in which the canvas is suspended from the upper beam. It moves along it with the help of rollers, which can be installed both on the sash and on the beam. The latter method is typical for structures mounted in warehouses and industrial facilities. The disadvantages of this type are the limitation in height and high requirements for the strength of the beam. Plus: on one cross member, you can install several leaves moving in the same direction or in opposite directions.

- Console model with suspension. Includes a pair of supports to which lightweight sashes are suspended. The model is suitable for a small area with a limited width of the driveway.

In order for the system to serve for a long time, it is important to pay due attention to the quality of the fittings - constipation, rollers, catchers and other parts. The structures can be divided into several groups according to the width of the entrance part. If it is narrow (4 m or less), lightweight welded gates will do. This option is often used in private construction. The average width (4.5-12 m) requires a reinforced, strong frame. With an indicator of more than 12 m, an upper beam with reinforced rollers is installed.

Sliding models attract with their burglary resistance and immunity to wind loads. Their operation does not require constant snow removal from both sides. Many types of sliding structures do not require height restrictions. The disadvantage of the models is the need for some free space for rollback behind the front of the gate.

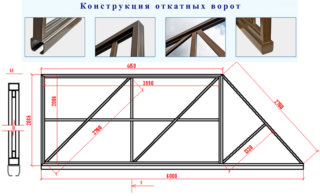

Schemes and drawings

The main parameters that must be indicated in the drawing include the width of the passage, the linear dimensions of the vehicles in use, as well as the distance between the machine and the fence supports (must be at least 0.3-0.5 m on each side). If the vehicle enters through the gate at an angle, the width is doubled. The height of the rollback segment is usually chosen so that it looks flush with the rest of the fence. A gap of about 0.1 m is left between the canvas and the surface of the soil.

Elements and accessories

System components can be easily purchased from specialized stores. The homeowner can choose a kit that is suitable for the operation of the planned weight of the canvas in a given opening width. In the absence of the necessary parts in local building stores, you can order them online.

The standard kit for the sliding structure includes top and bottom catchers, end and support rollers, holding platform and guide rail. It is also important to stock up on brackets and stubs. The channel makes the structure stiffer and prevents its deformation under the influence of wind gusts or accidental impacts.

Installation of sliding gates

The door insert is a 16th channel with concreting. In the general case, it is mounted at zero height of the arrival, but if the floor is planned to be tiled, the product is raised to its height. In order for the concrete mixture to completely penetrate under the channel during pouring, the formwork is made on the same level with it.

The depth of the mortgage is determined by the mark of soil freezing. In the middle lane, the structure is laid at a depth of 1.7 m, of which 0.2 m is diverted to a sand cushion. It takes 1 month for the concrete mixture to harden. After this period, you can start installing the gate.

To create a structure, the following types of equipment are needed:

- welding machine;

- grinder with a set of wheels;

- grinder and screwdriver;

- electric drill and fasteners for mounting facing material;

- building level.

The frame is welded from shaped pipes, while the cross members must be located on top of the vertical elements. This arrangement reduces the likelihood of corrosive processes. The crossmembers are equipped with plugs. A guide in the shape of the letter P is welded to the lower pipe. Then the frame is sheathed with a profiled sheet. Welding points are cleaned, and the frame is covered with a protective paint composition.

Only steel rollers are suitable for work. Plastic products should not be used. They do not tolerate low temperatures well. The parts are installed on the surface and the guide is rolled. It is also important to use the adjustment bolts. Some drives can stop the web at a specific location if the length is known. Steel catchers must be at least 304 mm thick. It is important to correctly adjust the bottom trap (it is placed last). When the sash enters it, the gate must rise 2 mm to relieve the rollers.

Plates for mounting rollers are welded to the channel in its center part, 10-15 cm from the edges. The trolleys are attached to them with bolts and nuts. After installing the gate, check the smoothness of the movement, make control measurements and adjust the position of the roller supports so that the structure is level.

If the system will be equipped with an automatic unit, you need to think about the wiring. This is done before pouring the base. The wire is placed in a hose with a corrugation and mounted in the foundation structure. You also need to lay the cables where you plan to mount the drive. Free endings are displayed above the base mark by a meter and a half. To successfully connect automation, you must strictly follow the manufacturer's recommendations.

On some models of sliding gates, the hole where the oil is poured may be plugged with a plug.This is done to prevent leakage during transportation. Before the starting start on the plug, unscrew the screw located on the side. Otherwise, oil will be squeezed out through the gaskets if the engine overheats. If, when trying to connect the drive, it does not work, you need to check the fuse located inside.