Not all owners of a land plot are satisfied with a deaf fence that does not allow light to pass through and gives a permanent shadow. The best solution in such cases are wire fences assembled from various types of mesh. As a rule, they are installed along the perimeter of adjacent territories, thus dividing the latter among themselves. In many cases, this allows you to avoid conflicts between neighbors due to the shading of someone else's site. It will not be difficult to build a welded mesh fence with your own hands, even for an inexperienced builder.

Mesh types

Accurately and efficiently mounted mesh fences reliably prevent unwanted guests from entering the fenced area.

Regardless of the type of mesh, all fences of this type:

- installed without much difficulty;

- do not require laying a heavy foundation; during installation, there are enough concreted pillars;

- can be used as a base for climbing plants;

- they are light-transmitting, which allows growing various agricultural crops and ornamental plants along them;

- due to the use of modern anti-corrosion and decorative coatings, they have a long service life.

In practice, welded meshes are used to equip mesh metal fences:

- gitter;

- welded mesh;

- masonry nets, etc.

All of them are distinguished by their high strength and successfully withstand mechanical and wind loads.

Welded mesh fences

The strength of the welded mesh, which is its main technical parameter, depends on two characteristics - the wire diameter and the geometric dimensions of the mesh. The smaller the cells, the stronger the web. Welded mesh with mesh sizes of 50x50 and 100x100 mm is widespread. There are also larger ones - 150x150 and 200x200 mm. The weight of the web is determined by the diameter of the wire from which it is made. They are light 3-6 mm) and heavy (8-40 mm).

On the market you can find:

- standard intake sections with dimensions 1.0x2.0 m, 1.5x3.0 m, 2.0x3.0 m;

- net in rolls up to 50 m long.

Most often, welded mesh is used for fences:

- non-galvanized;

- galvanized;

- with polyvinyl chloride coating;

- double protective coating (zinc + polymer).

Non-galvanized sheet is made of steel wire with a cross section of 1.2 to 10 mm. Having no protective coating, it quickly rusts and becomes unusable under the influence of climatic factors.

The application of a PVC coating to the non-galvanized welded mesh significantly increases its service life. Since the polymer is applied to the surface after welding, it does not corrode for a long time. Such a grid is used when fencing the territories of adjacent cottages or country houses as a continuation of facade fences that have a respectable appearance.

Galvanized steel mesh is most often used in the construction of country fences. The special zinc coating of the wire increases the service life of the fence.

Additional coating of galvanized mesh with polymer gives the fence an exquisite appearance and organically fits into the landscape of the site. Such a fence is practically not subject to corrosion.However, due to its high cost, it is not widely popular.

Installation of a welded mesh fence

When starting work on the construction of a welded mesh fence, you must first perform a number of preparatory work related to the availability of the necessary tools, the acquisition of the necessary materials, the marking of the route and the installation of supports for the future fence. Only after the completion of all these works, they begin to install the fence itself.

HIt is necessary to prepare the tools that you will need to perform simple work:

- shovel and bayonet shovels;

- plumb line or building level;

- Bulgarian;

- screwdriver or a set of screwdrivers;

- drill.

It is desirable that when installing the fence, it was possible to use a welding machine, a motor-drill and a concrete mixer. In extreme cases, the latter can be replaced with a container for the preparation of mortar.

The installation of a welded mesh fence is preceded by the selection and purchase of the necessary materials:

- Components for the preparation of mortar - cement, sand, crushed stone or rubble stone.

- Supporting metal posts (profile or round). As supports, you can use wooden poles, carefully treated before installation with an antiseptic.

- Fasteners - staples, metal plates, U-clamps, self-tapping screws, bolts with nuts and bolt hooks.

You may need a rigid wire with a diameter of at least 5 mm or reinforcement with a diameter of about 10 mm.

Perimeter markings

The installation of a welded mesh fence is preceded by marking its location. To do this, first, the territory on which the work will be carried out is cleared, and then the main line of the fence is outlined and the distance between its supports is determined.

The main line of the fence is marked with pegs, which are driven in at the points of installation of the pillars.

Supports are installed based on the height of the fence, the properties of the mesh, and the diameter of the supports.

Notes:

- The distance between the supports should not exceed 3 meters, which will avoid sagging of the canvas.

- The supports are installed in such a way that the joints of the canvases fall in the middle of the pillars.

- When erecting a fence from ready-made sections, the marking is carried out based on the dimensions of the latter.

Installation of pillars

The way the supports are installed depends on the type of soil and the total weight of the fence. In this case, the pillars can be installed by the following methods:

- full or partial concreting;

- hammering;

- backing, etc.

To install the pillars, pits are drilled with a depth of about 1/3 of the pillar length. In this case, the diameter of the pit should be several centimeters larger than the diameter of the support. A pit with a column previously inserted into it is poured with mortar, which is then leveled to the ground level. At the same time, using a plumb line or a building level, it is necessary to control the verticality of the installed supports.

The pillars are reinforced with spacers, which are dismantled after the mortar has completely solidified.

Fastening the fence

When attaching the fence fabric made of welded mesh, two design options are used: tension and sectional. In this case, the mesh in rolls can be cut-in, which provides for its preliminary fastening to the frame, or fixed directly to the supports, and then there is no need to cut it.

Fence made of rolled welded mesh

To fix the rolled welded web on the support pillars, you need to roll it out to its full length and leave it in this state for several days. They begin to stretch the mesh from the corner support, tying it on each pillar in several places with soft wire. To avoid sagging, a steel wire is pulled through the top row of cells and pulled between the posts.If necessary, the same wire is pulled through the bottom row of cells. This will somewhat increase the rigidity of the entire fence.

Having finally pulled the canvas, the soft wire is changed to special brackets or clamps. If the roll ends between the posts, it is spliced to the beginning of the other. If necessary, the excess mesh at the last support is cut off.

Roll mesh with PVC coating is fixed in a slightly different way:

- holes are drilled in the pillars for bolt hooks in advance;

- the mesh is fixed with hooks or press nuts.

To prevent the wire from jumping out from under the head of the screw, at the end of the installation work, the hooks are bent.

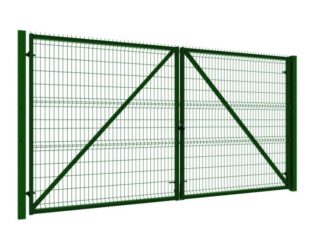

Installation of a fence made of sections with welded wire

You can significantly speed up the process of installing a welded wire fence if you use prefabricated panels. Usually they are purchased ready-made, but you can also make them yourself, using, for example, a masonry mesh.

Do-it-yourself sections and fences from a masonry mesh are made as follows:

- Rectangular frames are welded from the corners of 40x25 mm.

- All seams are thoroughly cleaned.

- A mesh cut to size is welded to the frame.

- Metal strips are welded to the previously installed supports.

- The fabricated sections are then welded to the metal strips.

- Upon completion of the installation work, the surfaces of the fence are treated with an anti-corrosion compound and painted in the desired color with enamel for outdoor use.

When using purchased sections, they are simply attached to the supports using clamps and brackets included in the delivery set of the fence. Also, these sections can be welded to the posts through additional metal plates.