Fencing made of profiled sheet is a convenient and affordable option. The steel sheet is highly durable, requires minimal maintenance, and is weakly corrosive, since it is coated with a protective zinc layer during manufacture. In order for the fence to fulfill its function, you need to select and install a lock on the gate made of corrugated board.

General requirements

The locking mechanism on doors facing the street is subject to high stress. Strict requirements are imposed on it:

- The lock on the gate made of corrugated board must be resistant to the action of water.

- The model for a wicket door in the private sector should be small. The door to the courtyard from a profiled sheet is a thin sheet construction, a massive lock will not work here.

- Resistant to dust - the mechanism used outdoors gets dirty much faster. For gates, it is recommended to choose lever models, since they are best protected from dirt from getting inside.

- Burglary resistance - the lock must guarantee a certain degree of security.

If moisture gets inside the device, any option will freeze in winter. It is recommended to install a protective visor above the wicket or even directly above the lock.

Varieties of locks for wickets by type of installation

A lock on a wicket made of corrugated board with your own hands can be like this:

- Hinged - the body of the locking mechanism is a separate element. The actual locking is provided only by the bow of the lock. The model is the cheapest, but unreliable.

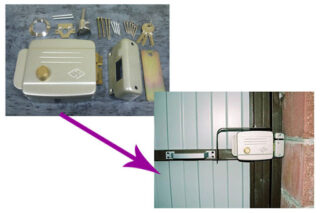

- Invoice - part of the mechanism is inside the wicket, regulating elements are outside. It is better to choose models that open with a key not only outside, but also inside, otherwise you will have to install an additional latch.

- Mortise - fixed to the front plate. The bar is securely fixed on the surface of the web, since it is it that provides resistance to burglary.

By the type of control, the following options are distinguished:

- Mechanical - opened manually with a key. Can be quite complex and reliable.

- Electromechanical or electrical - here the locking mechanism drives an electric current. While the battery is active, it is extremely difficult to hack the device - it is easier to destroy. Electric locks often do without a key, but are opened with a card or remote control. This drastically reduces the possibility of burglary, so that such a device is more often placed on the door of the house.

- Magnetic - the basis of constipation is an electromagnet. But unlike the previous version, this design has a drawback. If the electric one cannot be opened when the current disappears, then the magnetic one does not hold the leaf when it is turned off and the wicket turns out to be open.

A wicket made of corrugated board with a mortise or patch lock is the best option, combining quality and cost. Of these, preference is given to lever and cylinder:

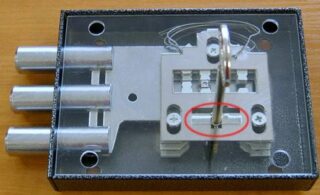

- Suvaldny is considered the most reliable option. When locking, several pins fit into the groove of the door frame and ensure a secure locking. In the event of a breakdown, the mechanism must be completely dismantled.

- Cylindrical - here the degree of protection depends on the complexity of the larva, which affects the cost. Plus the model is the ability to replace only the larva in the event of a breakdown.

A special modern version can be installed on the wicket made of corrugated board - smartlock or code. It opens with a code, a fingerprint, a retinal scan.

Installation of a mortise lock

The professional sheet is practical, but thin, you cannot insert a mechanism into the canvas here. The insert of the lock into the wicket from the metal profile is performed according to a different scheme.

Step-by-step plunge-cutting algorithm:

- The lock is measured and welded from steel in a 3 mm box. Its dimensions are slightly larger than the mechanism, therefore, gaps remain between the walls of the protective casing and the body.

- Mark the installation location on the profile and drill holes for the screws.

- In the casing and in the profiled sheet, grooves are made for the key, in the end - for the bolt.

- Bolt the box and lock. The bolts should be led out of the box on the inside of the wicket.

- A hole is made in the support post for the crossbar.

To embed a lever lock, you need several holes - for 3-4 levers.

Installation of the overhead product

How to put a patch lock on a wicket door made of a profile pipe depends on its design. If there is a horizontal bar of sufficient width, the constipation is placed on it. To do this, the body is fastened from the inside so that on the side where there are mounting holes, it goes beyond the bar, and on the other - with the larva and the handle, it turns out to be lower or higher.

- Installation is similar to installing a mortise lock without a protective box. Holes for self-tapping screws are drilled in the profile tube of the frame. If the swing leaf has not yet been sheathed with a profiled sheet, the device is screwed onto the bar with a screw and nut. If the profiled sheet is already standing, self-tapping screws are taken for fasteners and screwed in with a screwdriver.

- If the crossbar is missing or too low, proceed differently. In the place of fixation, an iron base plate is welded onto the frame. The patch lock is screwed onto the plate with screws, and then a key hole is cut in it and in the profiled sheet.

- Then the striker is attached. Its location is best determined when the mechanism has already been installed. Chalk or toothpaste is applied to the bolt of the lock, the gate is closed and the key is turned. The crossbar leaves a precise mark on the rack.

How to make a striking plate depends on what serves as a support post:

- Metal pipe of small section - an iron plate is cooked at the point of closure. A hole is made in it and in the pipe for the crossbar. The minimum plate thickness is 3 mm.

- Large diameter pipe - here you can do without reinforcement and cut holes directly in the pipe.

- Iron corner - a hole is cut out in the wide part, in the narrow part, a plate is first attached, and then holes are made.

Electric locks are mounted for the same laugh. But the installation involves installing the wiring and the battery.

Useful Tips

Installation of a mortise and patch lock is a relatively simple job, but it is carried out exactly according to the drawing. It is worth considering how much advice from professionals:

- You should not chase a high degree of protection. In such a wicket, the profiled sheet is the weak link. It is easy enough to cut, a complex lock will not help here.

- Modern modifications that open by fingerprint or code are simply more convenient.

- Although they put the locking mechanism on the frame, and not on the profiled sheet, preference is given to models with low weight.

You can choose and embed the lock on the sash yourself. It is important to choose a mechanism that is not too complicated, but practical and follow the installation instructions.