When building non-capital structures, saving money and the desire to do with improvised materials come first. A handmade potbelly stove allows you to solve the heating problem with minimal costs. Craftsmen offer many designs that are easy to replicate on your own. It is important to know the features of the stoves and avoid common mistakes.

- Features, advantages, disadvantages of a potbelly stove

- Furnace features

- Advantages and disadvantages

- Scope of application

- Calculation of parameters

- Popular solutions

- Gas cylinder oven

- Tools and materials

- Selection of a cylinder

- Freeing the tank from gas residues

- The procedure for making a vertical potbelly stove

- Working furnace

- Features of the sawdust oven

Features, advantages, disadvantages of a potbelly stove

It is customary to call a potbelly stove a metal stove designed to heat rooms with limited volume. The task of the device is to warm up as quickly as possible and give off heat to the room.

Furnace features

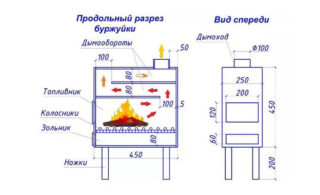

The design of a potbelly stove is simple and necessarily includes:

- a body that unites structural elements and limits the combustion zone;

- combustion chamber;

- ash pan;

- grate separating the firebox and ash pan;

- screen of the fuel chamber (partitions of the smoke circulation), which improves the efficiency of the furnace;

- chimney with an adjustable gate (valve);

- legs;

- brewing hole with lid (if necessary).

The shape and location in space of a homemade stove depends on the materials used. Gas cylinders, steel cans and barrels, rectangular containers and large diameter pipe sections are used as the basis.

A homemade potbelly stove in the manufacture should require a minimum of labor and purchased materials.

Advantages and disadvantages

The advantages of stoves include:

- simplicity of design;

- quick exit to operating mode;

- reliability;

- unpretentiousness to fuel, which is used as wood, waste from furniture workshops (chipboard and laminated chipboard), coal, mining;

- easy maintenance when using;

- compactness;

- various design options;

- versatility - heating rooms, cooking, warming up a steam room in a bath;

- ease of installation and mobility - the ability to remove the stove from the room during the warm season and use it for cooking outdoors;

- safety with correct installation and operation.

At the same time, the simplicity of the design leads to negative properties:

- potbelly stoves consume a lot of fuel;

- the device is suitable for heating one room;

- for work, it is necessary to regularly add fuel;

- hot gases quickly burn through the chimney and enter the room, which can lead to poisoning;

- average service life with regular use does not exceed 4–5 years;

- the surfaces of the body and the chimney are heated to high temperatures, and accidental touching them causes burns;

- it is impossible to accurately regulate the temperature in the room;

- it is difficult to select the combustion mode when cooking food.

It is not difficult to make a potbelly stove, therefore, at home, such designs are preferred even against the background of all the negative aspects.

Scope of application

Functionality, simple design and operation, low weight allow the device to be used in a variety of cases.A do-it-yourself potbelly stove for a summer residence will quickly warm up the room in any weather, and does not require maintenance between visits to the site.

The wood-burning stove in the garage only works for the required time and does not consume electricity. Potbelly stoves are used for heating temporary huts, construction cabins and truck bodies. Small devices can be taken on a fishing trip and used as a hob or smokehouse.

The device is not suitable for those places where it is impossible or difficult to control the round-the-clock operation of the unit. A working potbelly stove is not left unattended.

There is also an exception: a brick stove, built by hand, partially serves as a constant source of heat and can be used in rooms where it is necessary to maintain the temperature for a long time, for example, in rooms with farm animals.

Calculation of parameters

It is not possible to independently calculate the size of the stove, based on performance. The parameter will depend on many factors:

- type of fuel - wood species, moisture content of raw materials - and its amount in the furnace;

- exhaust capacity and valve position;

- installation site;

- the presence of partitions and screens in the combustion chamber;

- blower opening degree.

On average, textbooks on heating technology offer the following dimensions of the surface of the walls of the stove.

| Heated area, m³ | Wall area depending on the type of room, m³ | ||

| No outside walls | Corner | Freestanding | |

| 8 | 1,2 | 2,1 | 3,4 |

| 10 | 1,5 | 2,6 | 4,6 |

| 20 | 2 | 3 | 5 |

Based on the size of the combustion chamber, the chimney cross section is calculated. The minimum value in millimeters is calculated by multiplying the combustion chamber volume by a factor of 2.7. For a stove with a volume of 50 liters, the diameter of the chimney must be at least 50 * 2.7 = 135 mm.

For safe operation and reliable removal of combustion products, the following requirements are met:

- the height from the grate to the upper cut of the pipe is at least 5 meters;

- the number of turns at an angle of more than 30 ° - no more than 3;

- the maximum length of the horizontal section is 1 m;

- the minimum vertical section from the outlet of the potbelly stove is 60 cm;

- pipe material - stainless steel, asbestos cement;

- the distance to walls made of combustible materials is at least 50 cm, or more if the surface is heated above 45 ° C.

The above parameters are mandatory for buildings where stove heating is the only source of heat. Responsibility for deviations from the norms and the resulting negative consequences lies with the owner of the premises.

A non-combustible base is arranged under the stove, as a rule, a steel sheet is laid so that it extends 30 cm beyond the contours of the stove body.

Popular solutions

A drawing of a potbelly stove of different configurations is easy to find on the Internet. The most popular designs are from gas cylinders or barrels.

Depending on local conditions, attention is drawn to unusual fuels such as sawdust or waste oil. The options may be of interest to car services or woodworking workshops.

Sheet metal to make a potbelly stove with your own hands can be purchased at a reasonable price at scrap collection points.

Gas cylinder oven

You can cook a simple stove in a couple of hours from an old gas cylinder or barrel. At the stage of choosing a design, they pay attention to several points:

- with high ceilings, a vertical arrangement of the body is used, so it is more convenient to heat the stove;

- in low rooms, the unit is placed horizontally, so the room will contain most of the pipe, which gives off a lot of heat;

- it is easier to make a straight hob on a vertically standing cylinder, but the pipe will have to be brought out from the side, which will complicate the manufacture;

- stoves made from a barrel serve no more than 2-3 years, depending on the intensity of use;

- to work with thin-walled metal, you will need gas welding or a semiautomatic device; it is impossible for a non-professional to make sealed seams with an electric arc device.

Having decided on the design, drawing a drawing of a stove stove or finding a suitable one on the Internet, they start manufacturing.

Tools and materials

To work with a gas cylinder you will need:

- electric welding, mask, electrodes of a suitable diameter;

- grinder, protective screen for eyes, cutting and grinding wheels;

- gas or adjustable wrenches;

- drill with a set of drills;

- measuring instruments.

Additional materials are selected:

- steel pipe with a diameter of 100 mm;

- cast iron grates or pieces of reinforcement, with a diameter of 14 mm;

- steel corners for a homemade grate;

- door hinges;

- if necessary, parts for the manufacture of the hob - cast-iron lids, a piece of pipe along the diameter of the cooking utensil;

- pieces of reinforcement or profile pipe for the legs.

Selection of a cylinder

For the manufacture of a fully functional device, cylinders of 40-50 liters are chosen, stoves from a container of 12-15 liters are not enough for heating, frequent laying of firewood will be required.

Small cylinders are used to make portable cooking devices or products for heating KUNGs (unified body of zero dimension) or for van bodies of cars.

An alternative to a gas tank can be a freon cylinder used for refueling air conditioners or split systems.

Freeing the tank from gas residues

It is important to properly prepare the cylinder before starting welding.

Gas may remain in the container and explosive condensate is necessarily present, therefore, the order of work should be as follows:

- Open the valve, let the remaining gas evaporate. Work is carried out outdoors, away from fire and electrical appliances. Turning the cylinder over, drain the condensate.

- Unscrew the valve and try again to drain the remaining liquid fuel.

- Two or three times fill the bottle with water under the neck, displacing the gas.

After rinsing, the container can be operated safely.

Condensate has a persistent unpleasant odor, and spilled water is quickly absorbed into the floor and fizzles out for a long time. It is necessary to work in the fresh air.

The procedure for making a vertical potbelly stove

The vertical version occupies a smaller horizontal surface, which is important for small rooms, with an equal area, the heat transfer is higher compared to the horizontal arrangement of the case.

Work algorithm:

- According to the drawing, the holes for the doors of the combustion chamber and the ash pan with an ash pan are marked. For cylinders with other sizes, the proportions are observed.

- Doors are cut out with a grinder.

- A grate is made according to the inner diameter of the cylinder. If the farm has a pipe bender, then the fittings can be bent with a snake. Another option is to make a grate from segments of the desired length.

- The grate is welded to the walls, dividing the combustion chamber and ash pan, or placed on pre-welded supports.

- In the upper part of the body from the side of the side wall, a hole is cut for the chimney pipe.

- A 90 ° steel turn is welded, directing the outlet towards the further installation of the pipe.

- If necessary, cut a hole for the hob along the diameter of the prepared cast-iron lids.

- The front covers are welded or bolted on and sealed with an asbestos cord.

- Attach the pipe.

- A test furnace is carried out, if necessary, the places of smoke leakage are sealed.

After eliminating the deficiencies, the oven is ready for operation

The efficiency of the furnace can be increased by welding a horizontal partition into the combustion chamber. It increases the residence time of gases in the chamber and promotes their complete combustion.

A similar algorithm is used to make potbelly stoves of a horizontal arrangement.This configuration is more suitable for cooking ovens required, for example, for steaming feed in households.

Working furnace

Waste oil burns efficiently with a large amount of oxygen, therefore, furnaces using this type of fuel should be assembled according to schemes with two containers: an oil tank, also known as an evaporator, an afterburner and a secondary chamber for pyrolysis afterburning of gases.

Fuel is poured only before firing up or after the furnace has cooled down. To supply oil, it is advisable to make a steel pipeline with a tap, which allows you to extinguish the furnace at any time, and not wait for the oil to completely burn out.

It makes sense to make a stove from a 50-liter cylinder only for rooms with an area of about 90 m².

The thickness of the walls for furnaces during mining should not be less than 1.5 mm, otherwise through-burning occurs quickly.

Features of the sawdust oven

Sawdust-fueled stoves are economical and have a longer burn-out time. Putting sawdust in a 60-liter oven is enough for 7–8 hours of warm-up.

Structurally, such devices are performed according to a different scheme than ordinary wood-burning stoves.

The walls do not heat up to high temperatures, so any barrels are suitable for construction.

The simplest design includes:

- body;

- a partition with a central hole 5–10 cm in diameter;

- firebox door;

- cover;

- combustion products exhaust pipe;

- cone for laying sawdust.

Furnace algorithm:

- A cone is inserted into the opening of the partition in order to exclude the ingress of sawdust into the furnace.

- Sawdust is laid, at the same time tamping each layer.

- Carefully so that the sawdust does not crumble, remove the cone.

- Dry chips are lit in the firebox so that they give fire through the hole in the partition.

- When the sawdust begins to smolder, close the top cover, limiting the access of oxygen.

- Regulate the air supply to the furnace.

In operating mode, sawdust should smolder and not burn with an open flame.