At a summer cottage intended only for a garden and a vegetable garden, there is always a need to leave garden tools somewhere. There is a need to sit out the bad weather somewhere, relax after work, sometimes even spend the night. There is no need to build a house for this, even the simplest one - the problem will be solved by a change house from a bar with your own hands.

Does it make sense to build a change house with your own hands

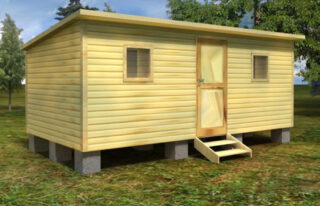

The change house is a cross between an outbuilding and a residential building. Its direct purpose is temporary housing. Change houses are used when a house is being built as a basis or for rare overnight stays in the country. Such a structure has minimal comfort, more often it serves as a workshop and warehouse.

In this capacity, ready-made building cabins, trailers, prefabricated panel houses are used in the country. However, more often buildings are erected independently from timber, boards and OSV sheets.

The advantages are as follows:

- the wooden structure is very light, it does not require a foundation;

- you can equip a mini-house with a veranda just according to your needs;

- do-it-yourself wooden change house retains heat well and does not need thermal insulation;

- the cost of construction is minimal.

If desired, the change house can be made mobile. To do this, a wooden house is installed on a frame made of a profile pipe and equipped with wheels.

Materials and approximate estimate

How much and what materials are needed for a 6 * 3 change house depends on the type of construction and height. There are several types.

- Shield is the simplest and cheapest option. Includes a primitive frame, essentially a plank frame and shields. After the need for temporary housing disappears, the change house is dismantled. For example, formwork is built from shields.

- Frame - a little more complicated, but stronger and more durable. The frame of the sections is built from a bar or double boards and the house is sheathed with plywood, OSV sheets, chipboard, clapboard. Sometimes the frame is sheathed even with corrugated sheet or metal sheets, but this is not the best solution. Iron conducts heat very well, so in spring it will be cold in such a house, and unbearably hot in summer.

- From a bar. In this case, the timber acts as a building element, like a brick. The bars are stacked on top of each other, forming walls. For construction, noticeably more material will be needed, so a log house is much more expensive. The change house weighs more, so for it you need to build a shallow or columnar foundation.

The calculation of the material for a change house with your own hands 3 by 3 meters is carried out taking into account the type of structure. If it is a frame, the bar is needed only for the frame: the lower and upper bundles, vertical struts. You will also need rafter boards and sheathing material.

If the change house is made of timber, the costs will be much higher. To calculate the required amount of material, it is necessary to divide the total area of all walls minus the window and door opening by the area of the front side of the timber. After counting, the value is increased by at least 15%, since damage is inevitable during construction and transportation of materials.

Choice of materials

The estimate for a change house 3x3 m also depends on the selected tree.

- Pine is an affordable, pretty beautiful wood. It is recommended to use pine, as it contains a large amount of resin, which makes it more resistant to dampness and decay. In addition, it is very easy to process and cut.

- Larch - they take it when the change house is going to be used for a long time. Larch is not only resistant to water, it only becomes harder under the influence of high humidity. Larch is not as beautiful as pine, but harder and more durable.

- The temp can be built from spruce. The wood is also resinous, so the structure will stand for several years in the rain. In terms of quality, spruce is worse than pine: it contains too many knots and tolerates high temperatures worse.

It is not recommended to build cabins from hardwood. Only medium and high density wood is resistant to water, like oak, beech, hornbeam, and is very expensive. Softwood - poplar, apple - are prone to rotting. Such structures need additional protection.

Step-by-step instruction

The step-by-step scheme for assembling a summer cottage from a bar is simple. Most often, a frame structure is made, since it is much cheaper.

Foundation

For a frame makeshift, it is not needed. However, contact of the tree with the ground must be excluded. For this, a site is created under the temporary hut. Remove the soil in the selected area for 1 bayonet of a shovel, fill the space with a layer of sand of 10 cm and crushed stone of 10 cm. Fill it with cement mortar. The site can be concreted, but it takes longer to dry.

The 3x3 m block can be placed directly on the prepared base. You can simply tamp the earthen pad, build supports from a couple of bricks and install the structure on them. This option is allowed in areas with dry climates.

If the temporary hut is completely assembled from a bar, a columnar foundation is erected. The step-by-step instructions are standard: they dig holes for the supports - usually at a distance of 1.5–2 m, compact the sand on the bottom, put the formwork and fill it with concrete. It is allowed to make brick posts.

Assembling the frame

Building materials for the change houses are treated with an antiseptic. If necessary, impregnation is done twice. The assembly instructions depend on the type of foundation and structure.

- If the temporary hut is placed on the site, the lower frame is made of a bar with a section of 150 * 100 mm. The connection is simple - half-wood, duplicated by metal corners. If the change house stands on a columnar foundation, the grillage serves as a strapping. In this case, when installing the posts, anchors are embedded in them, then the supports are waterproofed with roofing material and the posts are connected with a massive bar, fixing it to the anchors.

- Corner posts are placed - from a bar with a section of 100 * 100 mm or double boards.

- For bearing racks, a slightly smaller bar is taken - 100 * 50 mm. The verticality of the racks is checked with a level.

- The upper strapping is carried out by laying a bar with a section of 100 * 100 mm on the ends of the racks and pulling it together. If the roof is equipped, it serves as a Mauerlat.

- Fasten vertical racks with horizontal and diagonal crossbars according to the scheme. For fixation, nails of 80 mm are used.

- Install a box for window and door openings.

- The roof in the change house can be single-pitched or dual-pitched, in the first case, the opposite walls have different heights, and the entire roof structure is reduced to a row of boards vertically installed on the upper strapping.

For a temporary barn, a gable roof is sometimes built from a bar. To do this, the boards are cut at the selected angles, the trusses are assembled. You can do it easier: temporarily fix the ridge at the desired height on the clamps and attach the rafters directly to it on the metal corner on one side, and on the other, cut them into the Mauerlat.

The roof is laid with slate, profiled sheet, galvanized iron. Sometimes they use cladding material - chipboard sheets, for example.

Finishing work

When erecting a frame house, it is recommended to first build a roof, and then lay the floor and ceiling. This is a feature of this technology: here the frame is not part of the floor. However, in some cases, it is more convenient to immediately make the floor.

- Bottom rail or inner frame. If there is one, they attach the logs, plank the floor.

- If the roof is gable, it is recommended to fix the ceiling joists and sheathe the ceiling from below. If it is pitched, the roof protrudes as a ceiling.

- Walls are sheathed with OSB panels, plywood, chipboard, clapboard, ordinary grooved boards.

- If desired, the house can be painted, the lining can be varnished.

If necessary, the temporary hut can be insulated. In this case, mineral wool, waterproofing and vapor barrier films are laid in the space between the timber and the walls are trimmed from the inside. The floor will also have to be insulated.

Tips for building change houses

Manufacturing of building cabins according to drawings does not require a specification of materials, but it implies compliance with fire safety rules and some building recommendations.

- The wooden shelter is a fire hazardous facility. It should not be placed next to other wooden structures or a warehouse with flammable materials.

- If electricity is supplied to the change house, you must install your own shield and calculate the load correctly.

- The wires are hidden in a temporary hut in metal or plastic boxes.

- It is recommended to reinforce the attachment points with additional cross members.

- The change house should not be combined with a toilet or shower. However, it is permitted to install a summer shower tank on the roof.

A do-it-yourself temp at the dacha often turns into a stationary structure. Here they store inventory, store materials, spend the night, rest after work. In addition, the temporary accommodation can later be converted into a sauna, car repair shop and even a guest house.