The lattice for the openings in the walls of the gazebo is made in order to shade the space inside and improve the appearance of the structure, making it original. Wooden trellis gazebos create an impression of privacy, but retain the feeling of being outdoors. Cloth barriers, plastic barriers or metal barriers made of bars are not a complete substitute for wood trellises.

Main functions

The lathing is used in the construction of the gazebo, not only in openings, but also placed on roof sections. The technique helps to cover the area inside the building, but does not interfere with the movement of air currents and sounds. Such a visual barrier allows you to enjoy the weather, the noise of foliage, the roar of the waves, while remaining closed to uninvited observers.

The gazebo trellis performs the following functions:

- decoration of the building;

- shelter from views;

- giving additional strength;

- supports for climbing plants.

Crossed rows of wood strips give the gazebo an elegant look, visually lighten the structure. Architects use a good technique to make the object look complete. The integrity of the composition is obtained due to the fact that the lattice connects the details of the structure into a common ensemble.

Wood is a fairly strong material, so the interlacing of the slats can be considered as an element that increases the rigidity of the arbor frame. This increases the durability and reliability of the structure, since unstable supports wear out faster.

On the elements are plants that grow well and bloom on a lattice of wood. Such decoration further enhances privacy, while the person can observe the surroundings, while remaining invisible to others.

Wooden trellises are placed on gazebos made of different types of wood, and are also used on buildings made of other materials. Wood is combined with brickwork, concrete, stone walls. Sometimes the lattice weave is supplemented with forged iron elements.

Features and Benefits

Wooden gazebo mesh is available in single or double versions. In the first case, straight and cross elements of the crate are placed on the frame. On the bars of the box, a fold is made in the thickness of the doubled width of the rail (if mounted with an overlap). The depth is taken at the level of 1 - 2 cm, the accuracy of the adjustment of the rack ends depends on this. If inaccuracies in dimensions are made, the error is compensated by deepening the elements within reasonable limits.

A double structure is a structure containing 2 frames, which are made similarly to each other. Subsequently, planks are placed in the frames in opposite directions. For example, longitudinal rails are mounted in the outer frame, and transverse elements are nailed into the inner frame. The assembly of the ends is carried out with an overlap or in a groove, a careful fit is needed.

Advantages of wood for arranging gazebo trellises:

- ease of processing - the material is easily sawn, drilled, cut to size;

- strength of the finished lattice, resistance to strong wind;

- low cost of the product;

- versatility for the manufacture of structures of any design;

- ecological cleanliness of wood.

The main positive quality of wood is its aesthetic appeal.The textured pattern, the color of elements of different breeds can vary, this is also influenced by the method of processing the raw materials. For the lattice, a species of lumber is chosen, which is organically combined with the wood of the walls of the gazebo by design.

The planks are painted with enamel, stain is used, varnished. Sometimes an antiseptic impregnation is enough, which does not change the appearance, but protects against destruction.

Types of lathing

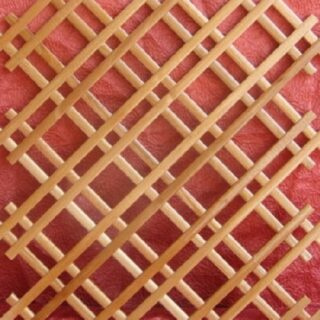

The wood mesh for the gazebo is made with a closed and open frame frame. The strips are superimposed on each other in two planes when crossing or connected, choosing recesses for placing one strip in another. The second method is more laborious, but the design takes up less space in thickness. If you need a beautiful and elegant product, the elements are joined into a groove. The first option is useful if you need to build a gazebo with trellises quickly.

By the type of crossing, lattices are distinguished:

- with rectangular weave or square type;

- with diagonal braiding.

In appearance, the products are arched, square or rounded. The developer chooses the type, he also determines the functionality (sun protection, decoration). What matters is the type of strips for the lattice, the angle of joining, the method of connection.

The grid pattern can combine diamond-shaped cells. Painstaking work takes a lot of time, since templates cannot be used. Such a model requires, when making with your own hands, a drawing for lathing the gazebo. For this, the opening is measured, the dimensions are transferred to scale on paper, and the layout of the rails is drawn up. A sketch is needed to calculate the length of small bars and their number.

Glass, cellular or solid polycarbonate is inserted into square cells, diagonal links can also be glazed, but you have to work hard. Carved lattices with patterns formed by folk craftsmen look beautiful. Such options can also be supplemented with standard rails.

Materials and assembly process

Various breeds can be used for arbor trellises. Durability, appearance of products depends on the quality of wood.

Use wood:

- Oak. The durable material is stained to enhance the design and tone. The wood is hard, difficult to handle by hand.

- Larch. Strength is not much inferior to oak, but the wood is soft, so it is more convenient to work with. Differs in resistance to moisture.

- Beech. The pinkish shade can simply be varnished in several layers. The tree is easy to plan, saw and grind. It quickly absorbs water, therefore it requires preliminary impregnation with protective agents.

- Ash. Heavy and durable material has medium density. Easily sawn, drilled, but deteriorates from atmospheric moisture, prone to decay. Before installation, treatment with antiseptics is needed.

- Coniferous materials. Spruce and pine contain resins that repel moisture. The wood has a pleasant smell, soft, medium strength.

- White alder. After sawing, it turns yellow, acquires a uniform color, in the air a beautiful orange color can be obtained without additional staining.

The decorative lathing of the gazebo is assembled manually with a rail. Connect the slats to each other and to the frame with nails or glue. For coating, antiseptic preparations, acrylic and pentaphthalic varnishes, paints, and stain are used.

The work begins with the manufacture of the frame, the docking places are lubricated with carpentry glue, the rectangularity of the ends is verified with a square. Self-tapping screws are screwed on the joints, nails are hammered. For self-tapping screws, holes are drilled, which are 0.5 mm less in diameter than the size of the hardware.

With the angular position of the ends, they are cut using a miter box at 45 °. The gazebo is fixed to the frame with wood screws. They are attached to the brick wall with dowels, to the iron pergolas are drilled with self-tapping screws for metal.

Connection of lattice elements into a single structure

After assembling the frame, thin slats are taken, which are placed diagonally or at right angles. The gaps between the elements are not standardized, they are accepted at will, the main thing is that the step is the same in all areas. An accurate template helps so that the geometry is correct, and the finished product is neat.

Similarly, other frames are filled with slats, they are then connected to each other with glue, screws, screws or inserted into the opening. Grilles are installed on walls, roofs, window openings. Sometimes the door entrance is framed with an incomplete lattice.

The order of work when connecting a groove to a groove:

- bait the initial rail, mark the junction with the second;

- the marked places are milled to half the thickness or cut out with a saw;

- do the same with the joints on all strips;

- coat the joints with glue;

- the rail is placed in a frame frame, fixed with small glass nails, so all the strips are mounted;

- the product is covered with stain and varnish.

Before manufacturing, the lumber is impregnated with preservatives, not forgetting to process the ends of the strips. Frames with a groove-to-groove connection are placed in one layer, so the second frames are not prepared. The rail is cut on a sawmill from a board of 50 mm, 120 - 150 mm wide. It is preferable to dry the material under a canopy before sawing.

Is it possible to do without a frame

There is an option when the lattice of rails for the gazebo is attached directly to the wall opening. The grids are set at 45 °, the size of each strip is pre-measured, sawn off exactly along the length, so as not to overspend on additional trimming. All sheathing rhombuses must have one slope, and their area must be equal to that of the neighboring cell.

Step-by-step instruction:

- make templates in the form of strips of various sizes for the convenience of subsequent marking;

- the slats are impregnated with an antiseptic, waiting for absorption and drying;

- the first bar is fixed to the window frame, checking the angle of inclination with a protractor, several such strips are stuffed along the width of the window;

- fasten to the frame with small studs;

- the top layer of elements is placed on top of the first, the slats are connected with glue;

- in openings with even ends, the decoration is not performed, and in the curly ones on top they place a decorative glazing bead;

- the assembled lattice is processed by the selected method.

The ends of the strips are cut at 45 ° after fixing the first longitudinal element, a mold made in advance helps in this. The length of the hardware is determined so that the edge does not protrude on the other side of the window frame. Otherwise, the leftovers are removed with nippers, and the problem area is soaked with linseed oil so that rotting does not begin.

Self-production

The corners of the frame are connected at 45 °, sometimes the groove-in-groove method is used. In the first version, the ends are marked with a protractor, the triangles are cut off. In the second case, wood at an angle of 90 ° is chosen at flat ends. The material is cut to half the thickness of the bar, the same is done with the end of the other part. For the frame, take a bar or rail 20 x 40 mm or 20 x 50 mm. This section is enough for the frame to be strong and not look heavy.

The frame is placed in the walls of the arbor in the following way:

- the formation of grooves and spikes;

- on hardware;

- with the use of an additional bar.

The first method works reliably, but it requires dexterity and skill in carpentry. The grooves are not formed by hand, but on a sawmill in order to obtain precise details. If there are errors during cutting, the joint will stagger. In this case, nails are used, from which the caps are bitten off or cut off so that they are not visible on the frame.

After fixing the strips in the box, the ends are cut off with a hacksaw for wood. When installing the ends in closed openings, there is no need to form folds. Overhead lathing is placed from two frames with nets, while the location of the slats is changed horizontally and vertically.

Rectangular cells are quicker and easier to make, but diagonal links look prettier.After using the tool, the places of the cuts are sanded with emery, but so as not to violate the size of the element.

Decorative techniques

Decorating is carried out with waterproof paints and varnishes for external work, preparations are used for impregnating wood based on mineral and synthetic oils with the addition of wax.

Use the techniques for arranging cells on the plane of the lattice:

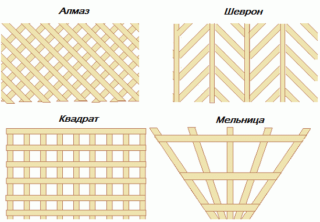

- Diamond shaped links. Parallel stripes are set at an angle, so this design looks impressive. Reducing the step between the parts leads to a dense curtain that is impervious to daylight.

- Chevron. This is the name of an ornament when a pattern is obtained by combining inclined planks and vertical elements. The structure is robust but difficult to manufacture.

- A cut rhombus. In this version, diamond-shaped cells are used, but their borders are formed by a number of parallel running strips.

The strips are placed not only in parallel, but placed so that their ends below are connected in the center, and upward diverge in the form of a fan. Such a drawing is called a mill. It almost does not block the visibility, but gives comfort thanks to the original cut.