The hearth in the house is built only for heating or provides for the possibility of cooking, heating water. A brick stove for a house on wood heats the air in the room directly or a boiler is built into it, connected to a pipe system and radiators. A long-term combustion unit with an afterburner of evolved gases is installed. The stove is placed in a bathhouse, garage, a multifunctional Russian stove with a stove bench or a wood-burning fireplace is placed in the house.

- Features of laying the hearth with your own hands

- Furnace structure

- Advantages and disadvantages of a brick stove

- Types of brick stoves for home

- Options for installing the stove in the house

- The choice of brick for masonry

- Choice of solution and preparation of components

- Required tools

- Step-by-step instructions for laying the stove

- Layout and foundation arrangement

- Erection of the furnace body

- Chimney construction

- Features of the long burning furnace

- Popular bugs

Features of laying the hearth with your own hands

The furnace is a complex structure. It processes fuel, generates heat, and smoke and combustion products are removed outside the room.

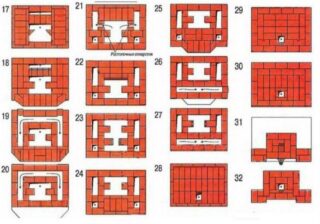

Independent work will require a layout for laying bricks in each row. Such drawings are called orders. The smoke inside the hearth goes through a difficult path - by heating the surface, it tends to exit. If the channels are folded incorrectly, the draft will disappear and the gases released during combustion will flow into the room.

For masonry, certain types of bricks are used, special solutions are used. Atypical materials are destroyed under high temperature conditions, carbon monoxide passes into the formed cracks.

Furnace structure

The foundation is placed below the level of the finished floor, it is isolated from moisture.

The design of a brick wood-fired stove for a home includes the elements:

- trenches are arranged on the surface of the floor, these are legs that contribute to the heating of the bottom;

- the blower delivers streams to the combustion area, there is an ash pan in it;

- fuel combustion occurs in the combustion chamber with grate;

- the firebox ends with a vault followed by the mouth of the furnace;

- further there is a pass and canals;

- there are two valves for cleaning;

- upstairs provide a stranglehold in the room, a chimney.

An internal cut is made in the chimney in front of the ceiling. At the top is the mouth of the smoke channel. Lining is provided inside to increase energy supply. The body and the lining are not tied, since the elements receive different temperatures when heated.

Advantages and disadvantages of a brick stove

The technical indicators of different models differ, but the general characteristics give an idea of the appropriateness of the application.

Advantages of a heating brick oven:

- large energy resource, which depends on the quality of the fuel;

- accumulation of heat by the walls, so the hearth gives off heat after the firewood burns out;

- beautiful view, the structure fits into the interior;

- low cost of construction;

- the possibility of long-term operation.

The disadvantages are the complexity of the masonry. It is necessary to build a foundation that is difficult to lay out in finished buildings, especially if the foundation is piled or columnar. A significant period of time elapses between laying, setting firewood and the beginning of warming up the room.

Types of brick stoves for home

Oven projects involve the integration of a cooking panel, a baking oven.The hearths are connected to registers, heating tanks are placed in them to obtain hot water.

When choosing, take into account the need for heating and other functions:

- Swede. Differs in efficiency and heating rate. Used in small areas or as additional heating.

- Small cooking stove-housekeeper. Combines heating, cooking food, drying food. Placed in the corner or in the center of the room.

- Kuznetsov's stove. Inside there are voids (hoods) where heated air collects, so the inner walls heat up more intensely.

The Dutch woman is a tall stove with a large firebox. It has no blower or grate bars, and air is supplied through an open door.

Options for installing the stove in the house

A brick heating stove for a summer residence or a private house is located near the internal partitions of the building. It is good if there are smoke channels in the walls that go out to the roof.

Location rules:

- the hearth is placed so that its walls give off heat to the room, an open installation simplifies the cleaning of the passages, maintenance;

- the structure is placed closer to the entrance in order to reduce the distance for the fuel tray;

- the stove is not placed near the outer wall with window openings, the massive structure darkens the room, the illuminated part of the room turns out to be filled with the stove.

If the structure is adjacent to the wall, a thickening (rough) is made on the reverse side, channels for heating the adjacent room pass through it.

The choice of brick for masonry

Only solid bricks are used. Any variety with internal holes, voids, lightweight versions does not transfer heat efficiently.

Types of bricks used:

- Refractory. Brick is placed on the inner wall of fireboxes, fireplaces, smoke channels. Heat-resistant elements withstand temperatures of + 1000 ° C without cracks, accumulate heat well.

- Ceramic red brick. The species is used for the device of the hearth body. Exterior masonry is carried out with decorative facing bricks. The brands M100 - M300 are used.

The smoke channels are laid out with baked clay stones. For lining inside the furnace, a refractory refractory variety is used.

Choice of solution and preparation of components

For laying a brick stove on wood for a summer residence and at home, they take an earthen solution that contains fatty kaolin, rainwater, river sand.

Components are selected taking into account the qualities:

- Clay. Choose fatty varieties, pre-soak the material for three days. After that, stir until a creamy mass is obtained, filter.

- Sand. Use simple or chamotte sand, the second type is used for laying internal heated surfaces. The sand is sieved to remove stones and coarse debris.

Water is taken without a greasy film on the surface, impurities. Cement is added to the solution if a smoke channel is made, starting from the attic area, or foundation laying.

Required tools

The solution is prepared in a convenient container; an electric drill with a whisk is used for kneading. You will also need a sieve for sand and for filtering the clay before placing it in the solution.

Other tools:

- hammer-pick, trowel (trowel), construction hammer;

- jointing for decorating the shape of the seam, water and bubble level;

- plumb line, tape measure, carpentry square, cord.

For beginners, you will need wooden ordering. This is a rail, on which, for ease of use, risks are applied, indicating the arrangement of adjacent bricks. You will need a rule to correctly align the elements on the plane.

Step-by-step instructions for laying the stove

When erecting, check the horizontality of the rows, the verticality of the walls and right angles. Bricks are laid with bandaging of seams.

Construction order:

- preparation of drawings for laying the oven with your own hands;

- marking, base arrangement;

- preparation of the solution and laying out the blower, firebox;

- masonry of the stove body with channels, installation of a water tank;

- the device of the channel for the removal of smoke.

The seams of the inner surfaces are completely filled with clay mortar and slugs are removed so that condensation and fumes do not accumulate in irregularities. First, they put bricks in a row dry, after trying on, laying on a mortar is made.

Layout and foundation arrangement

For brick hearths, the base must be built, since the structure is heavy, and the soil or floor in the house is not designed for such a mass.

Construction rules:

- the foundation is buried in the ground not less than half a meter so that the stove does not sag, does not tilt from soil moisture during freezing;

- the size of the base is chosen so that the edges protrude beyond the oven by 10 cm from each side;

- the foundation of the furnace is not connected with the base of the house; a gap of 5 - 6 cm is left between them, which is covered with sand.

The material is concrete, brick, rubble concrete. The surface is covered with three layers of roofing material on bitumen mastic or molten resin.

Erection of the furnace body

The dimensions of the combustion chamber are chosen according to the volume of firewood loading. Below, on the border with the blower, grate bars are placed, they are placed below the door so that coals do not fall out at the moment of opening. A gap of 5 mm is left between the iron and the masonry to compensate for the expansion.

The rows are made according to the ordering scheme in order to receive channels traversed for the products of fuel combustion. Bricks are beaten to size with a pickaxe, the hammer is placed in the direction away from you, the elements are set on the edge.

The water boiler is installed according to the manufacturer's instructions. The inner boiler is surrounded by two layers of tubs to increase the degree and speed of heating.

Chimney construction

There are types of channels:

- mounted, when the pipe is a continuation of the furnace and is placed above the body;

- indigenous, if the smoke collector is installed on its own base, sleeves go to it from the stove;

- wall, which are located in the main vertical fences of the house.

Chimneys are made of bricks, concrete with heat-resistant additives, steel sandwich pipes. Asbestos-cement elements are used at a temperature not higher than + 250 ° C. Other materials are enamelled iron, vermiculite concrete, composite compounds.

Features of the long burning furnace

The structures increase the efficiency of the stove, which makes it possible to save on firewood. The principle of operation differs from a simple stove in that an additional compartment is provided, where the afterburning of the evolved gases occurs. Convenience is that after laying one portion of firewood, you can not open the firebox for a long time.

Types of brick stoves for long burning:

- a classic stove, this group includes the Butakov stove, buleryan, in them the gases go up, and the fuel is ignited at the bottom;

- mine structure, where smoke goes to the neighboring area, where it burns out and gives heat;

- a hearth stove, in it firewood is set on fire at the top, and the smoke goes under the burning layer through the channels.

In gas generating facilities, gases burn out slowly. Firewood does not burn with a large flame, for the most part smolders with a lack of oxygen. The design provides for a heat exchanger, up to two circuits can be connected.

Popular bugs

It is better to put a brick in the masonry, which is pre-soaked in water for several minutes. The stones partially absorb moisture, therefore adhesion is improved, the solution in the seam does not give them water.

Inexperienced bricklayers narrow the mouth of the smoke duct, so the draft is reduced. Raw firewood burns badly, dies out. The oven door is installed with a gap to compensate for changes in size when heated. If this is not done, then the perimeter of the entrance to the furnace will crack.

It is better not to use metal partitions inside the stove; instead, a brick is installed on the edge. The oven is not located close to the combustion chamber. It is equipped over the firebox through gaskets in order to achieve uniform heating.