The microclimate in the steam room and washing room of the bath complex depends on the type of stove that heats it. The owners build a brick oven in a bath with a water tank with their own hands, in order to simultaneously provide comfortable conditions and heat the liquid. The heat center is performed with or without a chimney, and the water container is placed above or below the firebox.

- Advantages of a brick oven

- Types of firebox

- Types of brick stoves

- Necessary tools for the job

- Tips for choosing materials

- Refractory bricks

- Ceramic brick

- Cement

- Clay

- Sand

- Water

- Stove stones

- Furnace masonry

- Foundation

- Base masonry

- Clay preparation

- Ash pan and firebox masonry

- Laying the heater passages and installing the water tank

- Chimney

- Plaster

- Basic safety requirements

- Ways to improve efficiency

Advantages of a brick oven

Ceramic stones give off heat for a long time, which cannot be said about a metal unit. The result is quality steam.

The brick structure is quite powerful, which is why significant spaces are heated.

The stoves have a high fire safety index.

Types of firebox

Peat, firewood, coal are chosen for the bookmark. Electric heating elements and mode monitoring devices are built into brick ovens. There are options that simultaneously use 2 types of heating material.

There are hearths with heating, depending on the type of organization of smoke removal:

- in black;

- in gray;

- in white.

The unique small saunas, which have a low ceiling, are used to heat them up in a black way. There is no washing chamber, all washing takes place in a steam room with a stove bench and a bench for sitting. The stove for such a bath does not have a pipe, and the combustion products are removed through a small window in the steam room. Sometimes several holes are made with a cross section of 10 cm, which are overlapped for adjustment. A brick ceiling is made over the hearth to prevent a fire.

In the gray version, they arrange a classic steam stove in the bath. The smoke is supplied to the attic area, then it is discharged outside the structure through the auditory openings. The room heats up quickly, but soot is regularly deposited on the stones.

In saunas with white heating, the stove is separated from the steam nozzle by a metal lid, so a closed hearth is obtained. The baffle is removed after the fuel has completely burned out. The stove can operate continuously if fuel is regularly added.

It is preferable to take firewood, since their combustion is easier to control than coal.

Types of brick heaters

Any heater has a firebox with grates. An ash pan is placed under the grate to collect waste and supply fresh air when the blower door is opened. Furnaces are of constant and periodic action, a container for heating water is built into them.

- Constant action. The structure is equipped with thin walls and few stones. Supports +300 - + 350 ° С, in such furnaces there is an automatic equipment for controlling and coordinating heating. They use liquid, solid, gas fuels, electricity. For the bath, an electric heater is placed with an iron box on top, where stones are placed.

- Periodic action. It is better to build a simple brick oven for a bath with your own hands in family baths with short-term processes. An economical heater heats the passing smoke in the lower layer up to + 1000 ° С, and in the upper one - + 600 ° С. In this mode, the soot on the walls burns out.Hotbeds of periodic action are heated before the bath procedure, after which no firewood is put. Hot cobblestones produce good quality dry steam.

Compact devices use firewood, coal, briquettes. The result is very hot steam, and the temperature in the steam chamber of the bath reaches + 140 ° C.

The peculiarity is that the secondary gases enter the upper cavity of the chamber through the slots, and the smoke comes out through the channels through the opening in front. The side walls are made double, hot air circulates between the shells.

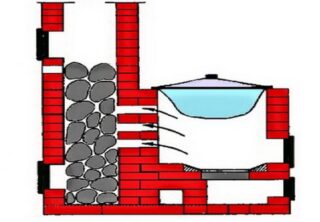

In a small-sized device, the volume for the tank and stones is 40 liters each, while in a sauna stove with an open brick stove, a water-heating container is placed next to the stones. The heating rate is controlled by an asbestos gasket between them.

Steel elements are placed in the bottom layer of stones for rapid heating. The slab is provided with a 47 x 20 cm cast iron slab with a thickness of 10 mm.

In order not to install a water heater separately, the heat of the furnace is used to heat the liquid. The tank can be positioned at the bottom or top of the structure.

- At the top of the stove, the smoke rising channel must be folded in a zigzag fashion in order to increase the contact time of the heated air with the masonry. Swirls from protruding bricks provide heat transfer. The damper is placed on top of the lifting channel, and the container and stones are covered with a light sheet steel cover.

- In a device with a bottom tank, the firebox has a greater length, and the volume of the chamber for laying stones is also increased. There is a kindling flap at the bottom. The lower position of the boiler is convenient for filling water and withdrawing it after heating. The heating rate is the most effective, since the end of the tank is in contact with the firebox, the other three sides are in contact with hot air.

You can do the laying of a sauna stove with your own hands simply and practically without a water heater. The chimney is passed through a stone valve. The tray for heating elements is made in the form of a container with inclined walls, which are heated from regularly circulating heated air. All attention is paid to the heating of the stones.

Necessary tools for the job

Other tools:

- jointing, level, plumb;

- tape measure, cord, square;

- wooden ordering with divisions, grater, rule.

For the solution, you will need a container, shovels, buckets.

Tips for choosing materials

The main material is solid brick. You cannot use lightweight elements with voids inside. Silicate bricks are not suitable, since the structures made of them absorb moisture and vapors, therefore they quickly collapse. Used bricks are thoroughly cleaned of soot and mortar, and their integrity is checked.

Refractory bricks

The material is used in the form of inner lining of fireboxes, chimneys, fireplaces. The elements insulate the walls from the flame, since they form a protective layer from the incandescent fuel.

Refractory bricks can withstand heating up to + 1000 ° C without losing their original properties, withstands repeated incandescence-cooling, and has low heat conductivity.

Ceramic brick

Received by processing clay and firing raw elements in ovens. Used for laying the main body of the furnace, chimneys. For the outer layer, a facing brick with improved decorative qualities is used.

In terms of strength, they are divided into grades from M100 to M300, the number after the letter indicates how many kilograms 1 cm² can withstand.

Cement

The cement-sand mass is not used for laying the furnace, it is used to prepare the base for the furnace, adding crushed stone to the mass. Prepare such a solution in small portions in order to lay it in the mounting position before setting.

Clay

Sand is added to the solution and a mixture is prepared at a concentration of 1: 1 or 1: 2, the composition is taken according to the fat content of the clay. Soak it 24 hours before stirring to get a mixture of the consistency of liquid sour cream.

The mass is filtered through a sieve, supplemented with sand, mixed until smooth. A good solution does not stick to the shovel and does not have lumps.

Sand

For the solution, the sand is cleaned of grass, gravel, roots, then sieved through a sieve. Small grains will give a thin seam when installing bricks. The amount of sand is determined by the fat content of the clay.

Water

You cannot take water containing silt, it must be low-mineralized and clean. Many minerals in the water cause stains to appear after the masonry dries. Such streaks are difficult to remove with plaster. It is best to use water collected after rain.

Stove stones

The first elements that come across will not work. Sauna raw materials should be heat resistant, high density and good heat dissipation. Wood stoves are equipped with stones of 7-14 mm, and electric ones - 5-8 mm.

For the heater, sea and river pebbles, basalt, volcanite, talcochlorite, jadeite, white quartz and crimson quartzite are used.

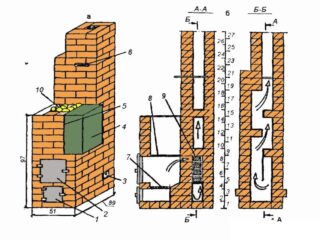

Furnace masonry

Before starting, they make the correct design of a brick oven for a bath with their own hands, the drawings of which can be taken from the Internet. Be sure to make a cut and a step-by-step plan for each row. When laying, check the rectangularity, horizontality, verticality, according to the instructions, the rule of bandaging the elements is observed.

They put the stove against the wall, where the smoke channels pass. The heating unit is not laid out near the outer wall with windows so as not to block the flow of light. Preparation consists in applying markings on the floor, digging a hole under the base of the stove.

Foundation

The brick stove is massive and heavy, so they build a foundation. The base is buried at least 0.5 m into the soil so that the structure does not tilt and sag when the earth is moistened and frozen.

The size of the foundation is 10 cm larger than the oven on each side. A gap of at least 5 cm is left between the foundations of the stove and the supporting wall of the house, which is sealed with sand.

They choose a concrete or concrete base, in dry soil they are laid from ceramic bricks on a cement-sand mortar. The surface of the foundation is equal to a similar solution, covered with roll insulation in 2-3 layers on mastic.

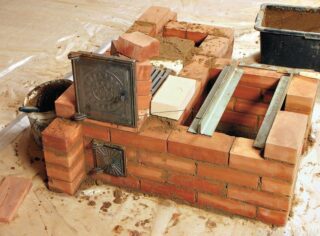

Base masonry

An asbestos sheet is laid on a clay solution, metal is placed on top. Put the first row dry, check the size and location of the seams. After that, the bricks are placed on the mortar, first corner elements, then along the lace - ordinary elements. The thickness of the wall (in ¼, ½, 1 brick) depends on the design of the stove.

Clay preparation

Frozen clay, which was outdoors in the winter, is better suited. The clay is pre-soaked in rain water, the period is 2-3 days. For this, boxes made of wood are used, upholstered inside with iron.

For bricks, a sandy-clay solution is taken; for plaster, the same mixture is used with the addition of lime.

Ash pan and firebox masonry

The dimensions of the chamber are chosen depending on the volume of one fuel load. The firebox is connected to the ash pan by grate bars. The grate is placed below the door so that burning elements do not fall out when opening.

The firebox is made with inclined walls so that the ash rolls along them into the blower. A gap of 5 mm is made between the metal and the brick so that the firebox does not collapse with different expansion of the materials.

Laying the heater passages and installing the water tank

The rows are laid exactly according to the ordering drawings in order to obtain passages passable for smoke. Gases can go inside the room if they do not find a way out due to the wrong location of the passage or dead end.

The boiler is installed in accordance with the design; with the internal version, two-layer masonry is used to increase heat transfer.

Chimney

Use internal channels in the wall or mount sandwich pipes with socket connections.The first element is connected to the outlet of the stove chimney, the rest are fastened with clamps to the walls.

A hole is made in the ceiling so that the pipe does not touch the wooden structures. A sleeve with a layer of thermal insulation is put on the chimney. They are fixed to the roof, covering the joint with a skirt made of rubberized material.

Plaster

The layer is applied with a thickness of about 15 mm. The stove is heated before use to speed up the drying time. The surface is moistened with water, a continuous first layer is applied. Wait for setting, apply a second layer. The area is rubbed with a plaster float to make it look even. After drying, they are whitewashed with lime.

You can heat the first time when the structure is completely dry. To do this, leave open views, blower doors, combustion chamber for a week in order to increase the circulation of fresh flows within all passages. If the oven is not dry, cracks will appear on the inside when heated.

Basic safety requirements

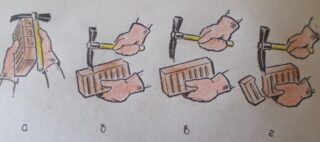

The brick is beaten off with a pickaxe in the direction away from you, placing it on its edge. The tool must be firmly attached to the handle (wedged) and secured with a nail or self-tapping screw. Handles should not have burrs, chips.

Scaffolds, floorings must be securely connected in order to be stable. The materials for the solution are filtered to remove small pieces of glass, sharp stones.

Ways to improve efficiency

The functionality of the stove can be increased by keeping it in good condition and regularly cleaning it from carbon deposits. Choose the right fuel, more often dry firewood is used for brick heaters. Use the correct combustion mode.

When designing, an effective way of transferring heat from the combustion chamber to the hot water boiler, heating stones is laid so that energy is not wasted on long transitions in the masonry.

The battery bursts accordingly within 2-3 years, the heater fails.