Smoking is a well-known cooking method. It takes time, but smoked products acquire a unique taste and are stored for a long time. A homemade smokehouse is made from a variety of materials.

- Differences between hot and cold smokehouse

- How the balloon smokehouse works

- How to make a smokehouse

- Schemes, drawings and dimensions

- Which cylinders are suitable

- Preparing the cutting cylinder

- Marking and cutting

- Cover making

- Making and welding of legs

- Chimney and furnace manufacturing

- Chimney draft regulator

- Painting

Differences between hot and cold smokehouse

There are 3 smoking options: hot, semi-hot and cold. The difference between the first 2 options is small, so only 1 and 3 methods are carried out at home.

Hot smoked features:

- the temperature of air heating in the chamber is 90–125 ° С;

- short shelf life - no more than 7 days, since the meat is not only smoked, but also partially baked;

- the meat becomes softer and more juicy, the taste intensifies;

- products after cooking do not need to be dried;

- as the food is baked, the amount of nutrients it contains is reduced.

Hot smoking is especially suitable for fish. It retains more moisture, becomes softer and softer. The skin also becomes softer.

Cold smoking parameters:

- heating temperature no more than 25 ° С;

- the cooking time is longer;

- the shelf life is much longer, since the product is not baked, but dried;

- after the end of smoking, fish and meat should be additionally dried;

- the meat becomes drier, the taste is closer to the dried product;

- with cold smoking, more nutrients are retained.

Food is also prepared in different ways. Before cold smoking, the meat should be salted for 2 weeks, before hot smoking - marinated.

How the balloon smokehouse works

For a hot smoked smokehouse, 2 gas cylinders are needed. Smoking on an open fire is prohibited, the firebox and working chambers must be separated from each other. In addition to cylinders, a chimney, frame, skewer stands are required.

Smoking is done in this way.

- The working chamber is made from a larger cylinder. It is placed horizontally. Since the dimensions of the container are standardized and not too large, you cannot hang food here, meat and fish are strung on skewers.

- The combustion chamber is made from a smaller cylinder. Chips are burned here.

- The chambers are connected in such a way that the resulting smoke is fed from below into the smoking compartment.

- The cooled exhaust gas is discharged through the chimney. It is better to make it higher so that the smoke does not interfere with the inhabitants of the cottage.

The main disadvantage of this design is obvious: you need to monitor the operation of the furnace manually and constantly.

How to make a smokehouse

A do-it-yourself smokehouse from a gas cylinder has a simple design. However, it is made by welding. In addition to the welding machine, assembly will require a drill with a set of metal drills, a grinder, wrenches, fasteners and pipes for the chimney.

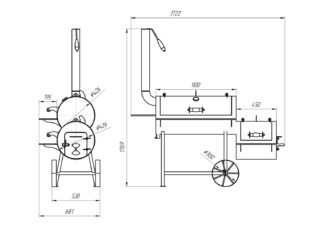

Schemes, drawings and dimensions

The dimensions of the smokehouse completely determine the dimensions of the gas cylinder used. The dimensions of the chimney must be calculated taking into account the volume of the resulting chamber. There is no need for a high draft; the smoke must remain in the chamber for some time and gradually be removed.

A drawing for a smokehouse can be done on paper or use any editor. Using such a scheme, it is easier to calculate the required amount of additional materials.

In the drawing, a direct and lateral projection of the working chamber is made.The structure of the firebox is much simpler. Here, only direct projection is sufficient. Calculate and indicate the number of blowing holes, the height of the cut. Be sure to note the physical dimensions of each part.

Which cylinders are suitable

Any cylinders are suitable for a smokehouse if they meet the following requirements:

- volume - not less than 20 liters;

- lack of rust, dents, scuffs;

- the inside of the case must not be damaged.

For aesthetic purposes, gas cylinders are cleaned of old paint. The vigorous red shade is not very attractive, and the coating will still need to be updated before use.

Preparing the cutting cylinder

It is imperative to completely empty the container of gas prior to use. Even with simple cutting, the metal becomes very hot, if some amount of blue fuel remains in the cylinder, a fire is possible.

Several methods are used:

- Fill the balloon with water through a hose and then drain. Liquid is denser than gas and displaces it.

- Immerse the container in a bath filled with water.

- They put the balloon in a hole 2 m deep and set fire to the wick leading to the body. In this case, the remaining gas is burned out. The method is risky, so it is better to partially fill the cylinder with soil and not approach the pit while the gas is burning.

When bleeding gas, water must be poured onto an area without vegetation.

Marking and cutting

They begin to make a smokehouse from a bottle of freon or natural gas with do-it-yourself markings.

- The door opening is placed horizontally and provides convenient product placement.

- The hole should have straight lines as the nets or skewers should be exactly parallel to the bottom.

- The incision should be less than ½ of the volume of the balloon.

After marking with a grinder, part of the cylinder is cut out. A door is then made from the fragment obtained. The same operation is performed on the second smaller cylinder.

Cover making

The lid is easy to make. To do this, a handle or two is welded to the cut out piece of the balloon. The roof can be removable or hinged. In the latter case, it is put on hinges. The hinges may not be welded, but riveted.

Making and welding of legs

The structure is placed on props - legs. For them, a profile pipe is taken, cut to length. The legs are bolted with male bolts or welded to the bodies of both cylinders. If a collapsible smokehouse is made, the support structure is welded and a cylinder is installed on it.

Parts of a foot sewing machine, car disks are used as a supporting frame. The mobile structure is mounted on bicycle wheels or casters.

Chimney and furnace manufacturing

The assembly of the structure is carried out according to the instructions:

- In both cylinders, holes are made for air supply. They are welded or hinged on the lid.

- In the main container, a part with a valve is cut off. The diameter of the hole must correspond to the diameter of the future chimney.

- A smaller cylinder, usually freon, is placed slightly lower than the working one. Their ends overlap by about 1/3. The bodies are welded to each other, and then a hole is made through which the smoke will enter the smokehouse. You can make a hole in advance.

- When legs or a frame are made, it is taken into account that the containers will be located at different heights.

- A grate is installed in the firebox, on which sawdust is placed.

- Holes are cut along the outer edge of the smokehouse for installing skewers.

- A vertical chimney is inserted into the hole and welded to the "petals".

The smoking cabinet can be complemented by grates for products, shelves for firewood.

If a cold smoking chamber is being set up, a tray is placed under the skewers to drain the fat and excess water.

Chimney draft regulator

When cooking different products and in different ways, it is necessary to regulate the flow of smoke and draft. For this, a hole is made in the firebox and a damper is installed.The lever from it should be located outside, so the flap is made large, and the cut for it in the body is cut out long.

Painting

Heat-resistant paint is used for staining, since the metal case heats up quite a lot, and the smokehouse should work for a long time.

Old paint is removed first. They clean the surface from rust and degrease with white spirit. Then they are primed and painted in 2-3 layers. You can use the smokehouse only after the coating has completely dried.