In the cold smoking method, low temperature smoke acts on the food. As a result, meat and fish retain a layer of fat. Often they assemble a cold-smoked smokehouse with their own hands from a barrel in order to do the job efficiently, to ensure effective functionality. In models, a smoke generator is sometimes installed for the smooth movement of smoke. It is easier to care for cold smoke machines, they do not get as dirty as hot smokers.

- Benefits and working principle

- Tools and materials

- Varieties of smokers

- Hot smoking horizontal smokehouse

- With internal combustion chamber

- From barrel and blowtorch

- From two iron barrels

- Electric option

- For cold smoking

- Making a smokehouse with a separate firebox

- Scheme and drawings

- Barrel preparation

- Marking and sawing a barrel

- Cover and handle making

- Barrel stand

- Firebox

- Chimney

- Lattice and hooks

- Fat collection stand

- Making a smokehouse with a smoke generator

- How to make an electric smokehouse from a barrel

- Principle and scheme of work

- What can you make a heating source from?

- Electrical installation

- Sawdust container

- Professional advice

Benefits and working principle

In hot chambers, fish and meat delicacies are obtained by heat treatment at + 100 ° C. Such food is not stored for a long time. Cold units operate with smoke from +35 to + 50 ° С, therefore fuel is saved.

The disadvantage of this method is that for the impregnation of products with smoke, a longer time period is required; preparation sometimes takes 4–5 days.

Smoke is emitted from smoldering wood chips. The design of the unit assumes the internal placement of products so that they are in the path of smoke with a low temperature. Harmful components from the stream precipitate, and meat and fish get a subtle smoky aroma.

Carcinogens are eliminated when condensate appears on the inside of the chimney, they are bound by drops. Moisture comes out when the smoke moves through the chimney.

Tools and materials

Before you make a smokehouse from a 200 liter barrel with your own hands, you need to prepare a grinder, welding. You will need a measuring and control tool, for example, a tape measure, a level, a pencil.

Purchase materials:

- sheet metal;

- metal corner;

- pieces of reinforcement;

- awnings, handle, door bolt.

You will need chimney pipes with couplings.

They use large and small iron barrels, as a result, a smokehouse is obtained from a container that is not needed on the farm. A wooden barrel can also be used for a cold smoking chamber, since the low temperature of the smoke cannot ignite the material.

The area near the chimney in such a container is trimmed with metal, so the structure can stand longer and not collapse.

Varieties of smokers

The chamber of any model is equipped with a cover to keep the smoke for a long time. The detail is included in the design drawing, the dimensions are indicated. The most convenient option involves the use of burlap, which covers the camera.

Hot smoking horizontal smokehouse

A hot-smoked smokehouse from a barrel is located horizontally, while the top of the container is welded with a metal sheet, and the lid is made on hinges. There is a hole on the side for installing a chimney.

Inside, at the bottom, a grate is attached to the guide corners, and the fuel is placed on the bottom of the barrel. The tank can be placed over an open fire.

With internal combustion chamber

A two-hundred-liter barrel is used, which is installed in a vertical position.Perforations are drilled in the side in the form of holes to organize the blowing. At the bottom they cut down a square firewood hatch and put a door.

The edges of the hole are trimmed with a metal strip. The products are placed on a wire rack, and a double bottom is made in the container.

From barrel and blowtorch

It is a practical portable design. A small iron barrel is used for smoking; it can be rounded or square. Such a smokehouse is taken on a trip to a summer cottage. The thermal process is supported by the flame of a blowtorch, open fire or gas stove. To operate the device, it is equipped with a tripod support.

From two iron barrels

The upper barrel is considered in the form of a smokehouse (vertical arrangement), and firewood is burned in the lower (horizontal) barrel. They put grate bars in the firebox, a blower. Wheels are often welded to such a structure for movement on the ground.

A hole is made between the barrels for the passage of smoke. In this place, a filter is installed, a wet cloth, burlap is used.

Electric option

A mains connection is required, and there is no need to open an open fire. Heating starts automatically when the button is turned on. In such devices, the possibility of coordinating the temperature inside the chamber is provided.

Electric smokers can be made with an open or protected heating element, provide for the use of a battery.

For cold smoking

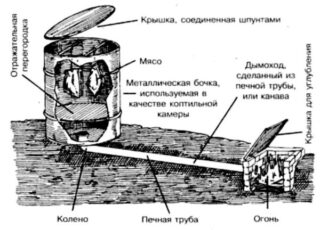

Before making a smokehouse out of a 200 liter barrel, you need to bring the pipe from the combustion source to the smoking compartment, for which they take a metal container for one hundred fifty to two hundred liters.

The longer the pipe, the lower the temperature the smoke will have. The main thing is to correctly calculate the distance so as not to get under-smoked meat. The firebox is built from bricks.

Electric models are smaller for increased portability. All cold smokehouses are distinguished by the degree of versatility. Homemade barrels are often used for different products, and purchased ones are for one type or are also intended for a large number of items. There are simple disposable designs for hiking or fishing.

Making a smokehouse with a separate firebox

The firebox and the smoking chamber are located separately; they are connected by a bypass pipe (about ten meters), through which smoke passes. A vertical pipe is also placed in the firebox to remove excess smoke and uniform heating of the smokehouse.

Attention is paid to the organization of traction; for this, the firebox is buried in the ground or forced ventilation is used.

Scheme and drawings

The structure is drawn on paper to calculate the size of the pipe.

The drawing indicates the installation locations:

- furnace compartment, top cover, door, chimney;

- areas for fastening pallets, hooks, metal gratings.

The smoke pipe is made at least 30 cm in diameter. The size of the barrel is chosen so that small and large carcasses, vegetables, mushrooms can be smoked.

The tank can have different dimensions, but the height of the smoking chamber is usually 3 times its diameter. In the cold smoking version, the container is slightly raised above the level of the firebox.

To install the smokehouse on the ground, make a brick support or weld a metal support. Doors are made from a cut-out side (placed on awnings), or made separately from a piece of steel.

Barrel preparation

Take a container of 200 liters such that it has not been in contact with chemicals, gasoline. If no other tank is available, the barrel is burned on a fire to remove residues on the walls and bottom.

Inside there should be no coating of paint, varnish, other plaque. Such layers are removed in front of the device, a stainless steel tank works better.

Marking and sawing a barrel

If the barrel is sealed at both ends, the top end is cut off. Before this, a line is drawn for an even seam.

Step-by-step instruction:

- sawing a hole for laying fuel 5 cm from the bottom;

- the cut out part is placed on the hinges to make a door;

- holes are made in the bottom for air supply;

- a round iron membrane with holes is fixed at a height of 25 cm from the bottom.

A hole is made for mounting the pipe.

Cover and handle making

The lid is made so that it sits as tightly as possible, the diameter is chosen 1 cm larger than the tank. For tightness, a water seal is made of iron tape around the circumference of the container, which is welded to the top at 45 °. Water is poured into the gutter. Without a water seal, the unit will lose some of the smoke. The handles are welded to the door, lid, placed on the sides of the barrel in order to carry it over a distance.

Barrel stand

Ceramic red fired brick is used, this solution is most relevant. Stones can also be used, but they must be chosen the same height. The bricks are placed in mortar or simply substituted as a temporary option. Otherwise, a stand in the form of a tripod is cooked from a corner, reinforcement or a profile pipe.

Firebox

A budgetary way to organize the combustion of firewood is to dig a pit in the ground. Firewood is placed in it, while the volume of smoke must be regulated.

Other options for the stove are made of brick, stainless steel, galvanized.

For the firebox, they take fired red or fireclay fire-resistant bricks on clay mortar. A square body is welded from metal, holes are made in it for a supply pipe to the smokehouse and a vertical chimney.

Chimney

The pipe goes under the product chamber, and the diameter and length are important. You can make a chimney out of bricks and run it under the soil to ensure airtightness. A long pipe made of asbestos, a metal, is usually unstable, so it is fixed in the center on an additional stand. The support is made of brick or reinforcement.

Lattice and hooks

The grill is made removable, they take an improvised part from the refrigerator, use a masonry mesh. The cells are selected in such a way that small products do not fall through.

For large carcasses, stainless steel hooks are used, they are hooked onto the transverse rods. The carcasses should not touch one another, so three bars are sufficient.

Fat collection stand

The pallet is made with sides along the edges so that fat from fish and meat does not drip onto chips. This will eliminate fuel attenuation. The size of the pallet is made one centimeter less than the diameter of the barrel, it is performed in the same way as the lid. For him, they put a tripod inside to raise it above the wood. Place the pallet with the sides up.

Making a smokehouse with a smoke generator

The device increases the draft inside the unit, as a result, the smoke goes evenly and enters the smoking compartment. A compressor is used which is installed in the fish tank. You can use a used one or buy a new one. The device is mounted using a double-sided pipe, which is welded into the barrel.

To build a smoke generator chamber, use any container, for example, a milk can, a fire extinguisher cylinder, a large thermos, a steel pipe. Dimensions are different, depending on the power. Shop devices have a technical passport, where everything is indicated. Home-made devices count on a certain power, the indicator depends on the volume of the smokehouse.

For the correct connection of self-made installations, a trial test is carried out so that the dimensions of the tank and the smoke generator match. Connection drawings can be found on the Internet. To connect the pipe to the generator, fittings are used that are welded into the hole in the tank snacks. Can be replaced with a threaded connection if possible.

How to make an electric smokehouse from a barrel

The assembly will take one working day, it is necessary that the parts are at hand and there is a planning drawing of the connection of the elements.

You will need:

- iron barrel;

- wheels for moving the container;

- heating element;

- wire with plug for connection.

They also prepare a thermostat, a container for sawdust, a thermometer, a grate, a pallet.

Principle and scheme of work

The electric smokehouse consists of a heating element and a sturdy body. The element receives power from the mains, heats up the sawdust, they begin to smolder. The fuel gives off smoke which warms up delicacies in the chamber. The body is represented by an iron tank, and the heater is taken from any household appliance.

What can you make a heating source from?

The spiral or metal heating element is removed from the old iron, kettle, electric stove. The main thing is that the ten can still serve for a certain time. The plug of the device is removed from the socket, then the device is disassembled, the heater is removed.

Electrical installation

The element is connected to the barrel using wires that are placed in the holes at the ends. Two holes are drilled on the heating device, the power cable is inserted taking into account the plus and minus. Check the operation of the heater by putting some sawdust on it. A good design is one that gives off smoke after 5 to 6 minutes.

Sawdust container

The tank is the place where small wood waste is placed. Sawdust burns here, so the walls are made of non-toxic materials that do not emit toxic substances. The chamber must have a certain strength, use cast-iron old pots, high pans, iron bowls.

Raw meat of any kind is put into the barrel, for example, poultry, beef, pork, rabbit. Fish is well prepared, and you can take fatty and not very varieties. It is allowed to smoke lard, pre-pickled offal, seafood. The grill is used for smoking vegetables and mushrooms.

Professional advice

The main thing is to cool the incandescent gases to the desired temperature. A pipe of the required length is used, which is sometimes chosen in a practical way.

The second cooling method is the use of a flowing liquid. A water cooler is made from tubes, the material is brass.

The third way is to create pipe bends. It is used when using logs as fuel, not suitable for sawdust.

Take an electric motor with a pulley. Above the pulley, you vertically fasten a pipe with a diameter of 150..200 and a length of 300..400. You put a chock in the pipe, the chock stands on the pulley with its butt end. Everything turns on the motor, from friction the chock smokes, smokes, dry ones are burnt.