The cold smoked wood smokehouse allows you to spend time in nature and cook delicious food. It is not difficult to make a wooden smokehouse with your own hands, but this process has its own nuances and features that must be taken into account in order to achieve a good result.

Features of cold smoking

Smoking is one of the methods of cooking and simultaneously preserving products of animal and plant origin. Its essence lies in the effect on the raw supplies of the smoke emanating from smoldering firewood. During this process, meat and vegetables are disinfected, saturated with a specific aroma and enveloped with a thin oil film that protects against the penetration of insects and microorganisms.

Smokehouse made of wood for drying is used to process the contents with smoke, the temperature of which does not exceed 40 degrees. With such an effect on the products, all the useful substances are retained in them, and the shelf life due to the duration of cooking is much higher than that of hot-smoked supplies. Curing in the smoke takes several days, but the cost and patience are well worth it.

Smokehouse made of wood

Advantages of a wooden smokehouse:

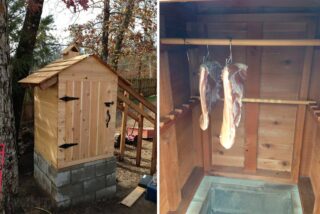

- The wood is easy to handle. It can be given any shape and size. The body of the house looks good with carvings, firing and external decorations.

- Interesting appearance. The construction gives the site exoticism and originality.

- Good thermal insulation properties. Due to this, a constant temperature is maintained inside the chambers.

- Availability of material, the possibility of making it with your own hands, maintainability.

There are few negative sides. It is necessary to equip a long underground chimney so that the gases cool down until they come into contact with food. The next aspect is fire safety. Dried wood can ignite at the slightest spark. In addition, the boards deteriorate from dampness; you can extend the service life of the structure by arranging a canopy that will protect the smokehouse from rain, snow and ultraviolet radiation.

Do-it-yourself cold-smoked smokehouse made of wood is made in a stationary and mobile version. Regardless of the type and size, the structures have the same structure.

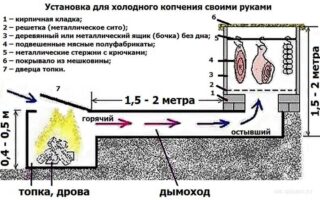

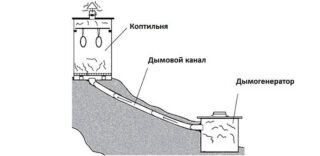

- Firebox (smoke generator). It is a metal container or just a hole in the ground. The niche is closed with a lid to minimize the access of oxygen to the fuel. This causes the wood to smolder, giving off little heat and a lot of smoke.

- Chimney. It is made of steel or ceramic pipes, and is also made in the form of a ditch, covered with a deck. The length of the channel depends on how efficiently the combustion products will cool in it.

- Smoking chamber. Made in the form of a box made of solid wood. Inside, the structure is equipped with shelves, stands, nests for the location of various types of provisions. The door, as a rule, is made on the facade, but it can also be installed from above.

- Exhaust pipe. Designed to create sufficient draft to ensure the movement of smoke from the firebox to the working chamber. It is made of any materials except asbestos and plastic.

The principle of operation of the smokehouse is simple, as well as its design - hot smoke from burning wood is drawn into the channel, cools down in it to an acceptable temperature in the direction of movement, and then enters the chamber with the products, where it gives them taste and color. Then it comes out of the chimney and disperses in the air.

Smokehouse in the form of a house with a pitched roof

If the smokehouse will be operated regularly throughout the year, it is advisable to stop at a permanent, capital-type structure. As a base for the house, you can use supports made of bricks, pipes or timber. It is advisable to choose materials that are resistant to natural factors. The supports themselves are left as they are, sheathed or used as a base for a small cabinet. The box can be used to store smoking devices, firewood, and various small items needed in the household.

If a portable model is chosen, it should be made compact, lightweight and collapsible on grooves, hinges and locks. To make the hut look good, the shed roof is made one-piece, and the exhaust pipe is attached to the back or side. This will not affect the quality of the drying process. The flooring itself is made of thick planks with grooves that are tightly connected to each other. Copper tiles can be used as a decorative element. It weighs a little and looks out of place.

Schemes, drawings and dimensions

For the procurement of large batches of pickles, it is necessary to build chambers with a volume of 100 liters or more. To create the required amount and concentration of smoke, it will take a lot of firewood, and this is effort, time and money.

The owner is quite capable of designing a smokehouse and making a drawing on his own, there is nothing complicated here, the calculations are simple, errors are permissible. To save time, you can use ready-made projects that, after implementation, have shown themselves well in business.

Necessary materials

- pipes for chimneys with a diameter of 100 mm;

- planed boards 20-30 mm thick;

- timber 40-50 mm;

- fittings - handles, hinges, thermometer;

- self-tapping screws;

- roof covering;

- metal grill;

- hook wire;

- a pallet of their iron.

For the manufacture of a smoking chamber, you should use wood that does not contain resins:

- cedar;

- oak;

- alder;

- Linden;

- Birch;

- aspen.

Alternatively, waterproof plywood is suitable.

When buying boards, you need to pay attention so that there are no knots in them. Over time, they shrink and fall out. Chipboards should be categorically abandoned. When heated, they emit harmful substances and quite soon exfoliate.

The master will need the following devices:

- hacksaw;

- jigsaw;

- drill;

- screwdriver;

- level;

- roulette;

- square;

- pencil.

It is imperative to use protective goggles and gloves.

Manufacturing process

Following step-by-step instructions, any master is able to build a high-quality, beautiful and durable smokehouse.

A collapsible structure is erected in the following sequence:

- Marking is carried out on the ground.

- A ditch is made for the chimney. A pipe is placed in it and buried.

- A pit is dug under the base plate. The bottom of the ditch is compacted, a cushion of sand and gravel is poured onto it.

- Slabs, bricks are installed or concrete is poured.

- The firebox is equipped, the chimney pipe is brought into it.

It remains to make a camera, put it on a pedestal and connect the pipes.

Smokehouse with a smoke generator in the ground

The structure is being erected in the following order:

- Digging a trench with a length of at least 300 cm. Laying bricks on its bottom to make a channel.

- Ditching with steel or concrete slabs. Backfill on top of the earth.

- An excerpt from the far edge of the pit, installing a smoke generator in it.

- Construction of a house, starting with the arrangement of the foundation and ending with the laying of the roof.

In all cases, the final stage is the decoration of the structures.

Recommendations for manufacturing and operation

Initially, you need to choose the right place for construction. The smokehouse should not be located next to residential buildings and above underground utilities. It is advisable that the smoke does not go to the neighbors. The lumber needs to be treated with an antiseptic, this will significantly extend its service life.

Since the structure must work continuously for several days, the smoke generator should be covered with a thick burlap or tarpaulin so that smoldering does not stop, but the fuel does not run out quickly.

While the structure is not in use, it is advisable to cover it with a cover to protect it from moisture, sun and insects.